A kind of treatment method of electrolytic aluminum carbon-containing waste residue

A treatment method and technology for electrolytic aluminum, applied in the direction of improving process efficiency, etc., can solve the problems of recycled product graphite, low fluoride purity, inability to achieve harmless carbon residue, incomplete harmless treatment, etc. The effect of full contact, low cost and low running cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The carbon slag is processed in a tunnel kiln.

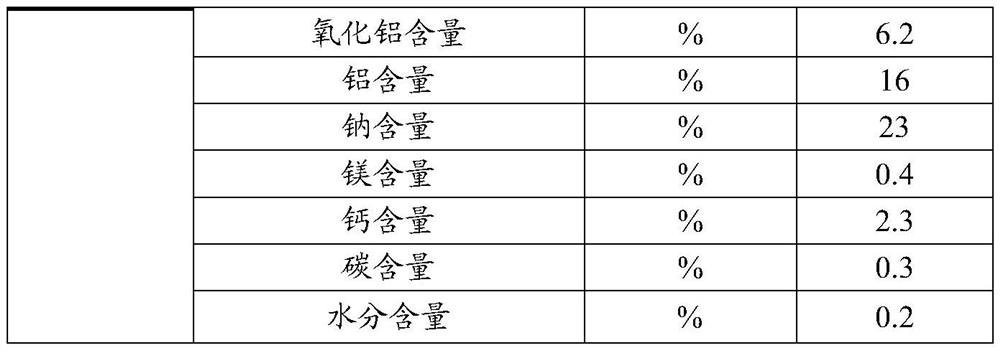

[0034] The carbon slag is broken and sprayed with the catalytic liquid for 5 minutes. The mass percentage of the catalytic liquid is: NaCl 15%, KCl 10%, NaF 5%, VCl 2 1%, the rest is water, using a 35-meter-long tunnel kiln, the kiln car advancing speed is 2.2h / car, the loading capacity is 660kg, the pretreatment section is 10 meters, the temperature is 350°C, the oxidation section is 15 meters, and the temperature is controlled at 670-680°C , after 12 hours of oxidation, carry out the slagging section. The oxidized residue weighs 528kg, and the residue is mainly fluoride. The detection indicators are shown in Table 1.

[0035] Table 1

[0036]

[0037]

Embodiment 2

[0039] Tunnel kiln is used to process carbon slag flotation carbon mud.

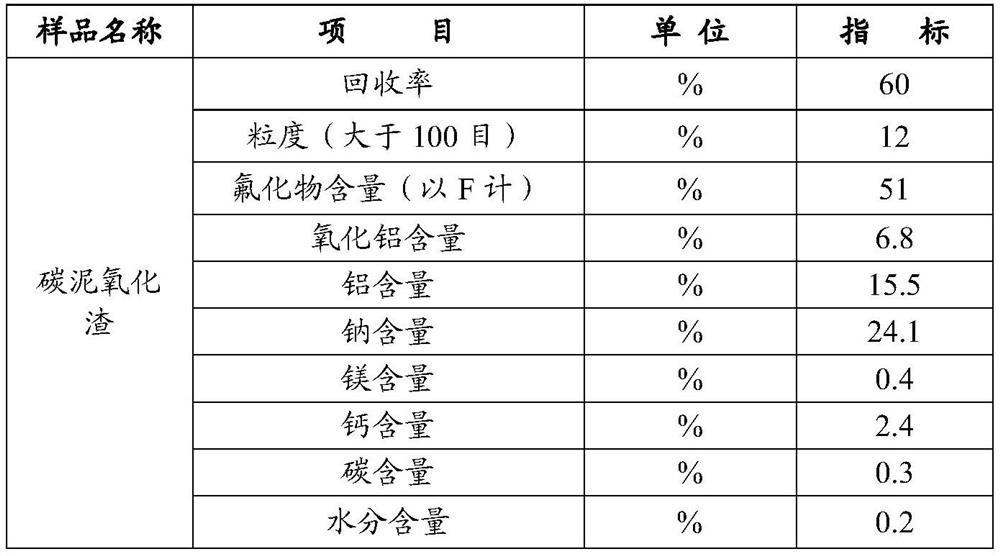

[0040] The flotation carbon mud is sprayed with catalytic liquid for 5 minutes, and the mass percentage of catalytic liquid is composed of: NaCl 18%, KCl 5%, NaF 15%, VCl 2 1%, the rest is water, using a 50-meter-long tunnel kiln, the kiln car advancing speed is 1.5h / car, the loading capacity is 650kg, the pretreatment section is 10 meters, the temperature is 350°C, the oxidation section is 20 meters, and the control temperature is 650-685°C. After oxidizing for 10 hours, carry out slag discharge. The oxidized residue weighs 390kg, and the residue is mainly fluoride. The detection indicators are shown in Table 2.

[0041] Table 2

[0042]

Embodiment 3

[0044] Rotary kiln is used to process the scrap cleaning material.

[0045] The residual electrode cleaning material is sprayed with catalytic liquid for 8 minutes, and the mass percentage of catalytic liquid is composed of: NaCl 12%, KCl 6%, NaF 7%, VCl 2 2%, the rest is water, using a 60-meter-long rotary kiln, the rotary kiln speed is 0.4r / min, the loading capacity is 650kg, the pretreatment section is 10 meters, the temperature is 350°C, the oxidation section is 32 meters, and the control temperature is 650-685°C. After oxidizing for 8 hours, carry out slag discharge. The oxidized residue weighs 390kg. The residue is mainly fluoride and iron impurities. The detection indicators are shown in Table 3.

[0046] table 3

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com