Preparation method and application of nife-ldh oxygen evolution electrocatalytic material

An electrocatalytic material and oxygen evolution technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problems affecting the catalytic performance and stability of electrodes, raw material toxicity It can improve the catalytic activity and stability, the preparation process is simple and feasible, and the condition requirements are low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

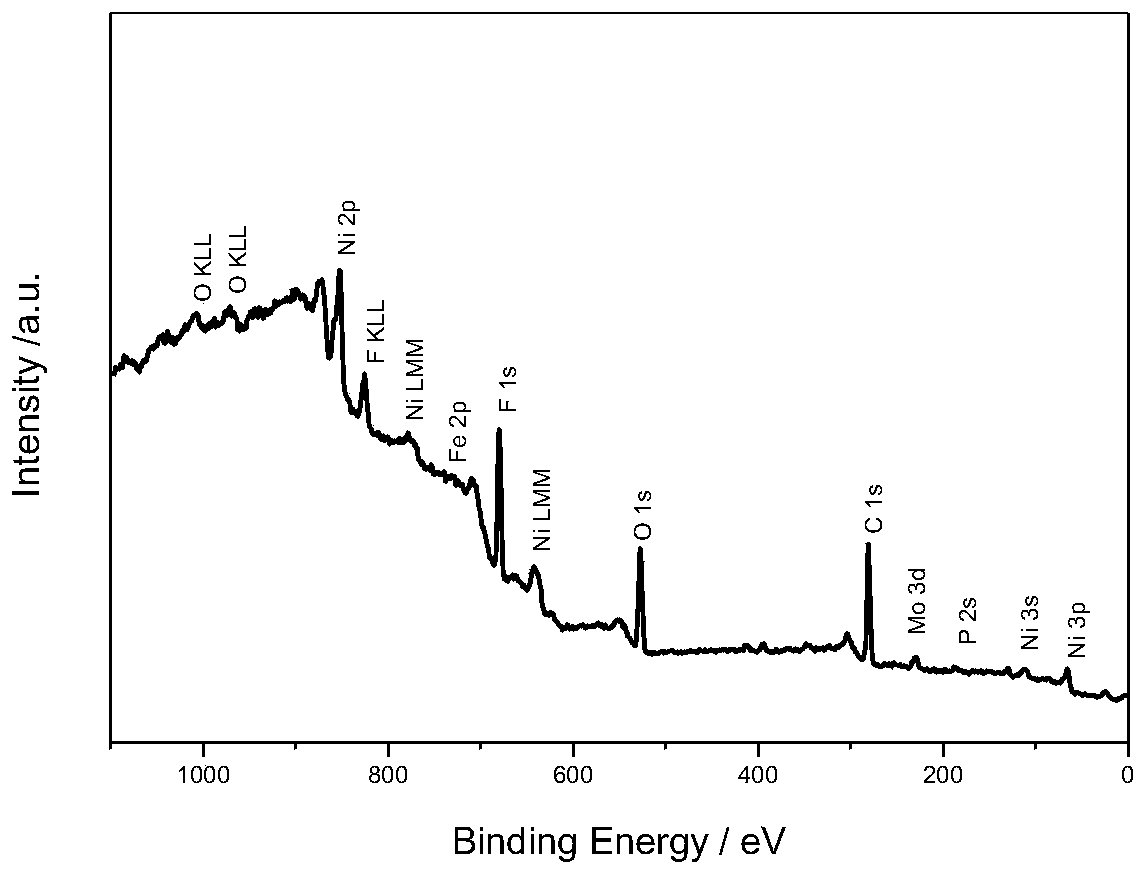

[0036] (1) Pretreatment of the substrate: the Ni-Fe alloy substrate is cut into a rectangle of 3.5cm×0.5cm, the 1.5cm of the upper half is used as the clamping part, and the 2cm of the lower half is used as the actual use part. Soak the cut sample in acetone for 20 minutes, then immerse it in isopropanol for 20 minutes, and finally immerse it in alcohol for 20 minutes. Soak the cleaned substrate in absolute ethanol.

[0037] (2) Anodic oxidation of the substrate: the electrolyte composition used in the anodic oxidation process is 2wt% NaF, 4wt% (NH 4 ) 2 MoO 4 , 20 wt% H 2 O, 30 wt% glycerol and 44 wt% phosphoric acid. The lower half of the substrate pretreated in step (1) is immersed in the electrolyte, and the clamping part is connected with the anode electrode. The anodizing device is SP-150 electrochemical workstation, using a three-electrode system, the substrate is used as the working electrode, the platinum electrode is used as the counter electrode, and the saturat...

Embodiment 2

[0046] (1) The pretreatment of the substrate is the same as that of step (1) in Example 1.

[0047] (2) Anodic oxidation of the substrate: the electrolyte composition used in the anodic oxidation process is 3wt% NaF, 7wt% (NH 4 ) 2 MoO 4 , 20 wt% H 2 O, 30 wt% glycerol and 40 wt% phosphoric acid. The lower half of the substrate pretreated in step (1) is immersed in the electrolyte, and the clamping part is connected with the anode electrode. The anodizing device is SP-150 electrochemical workstation, using a three-electrode system, the substrate is used as the working electrode, the platinum electrode is used as the counter electrode, and the saturated calomel electrode is used as the reference electrode. Boost the voltage from the open circuit potential to 7.5V at a rate of 15mV / s, keep a constant voltage at 7.5V for 3min, and then -2 Maintain a constant current for 20 minutes under the current density, and the temperature of the electrolyte is 25°C.

[0048] (3) After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com