Structure and Construction Method for Reducing Pile Length in Deep Soft Soil Layer by Forming Composite Foundation

A technology of composite foundation and construction method, which is applied in the direction of foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of prone to bending damage, difficult construction, complicated process, etc., achieves convenient operation, saves materials, and overcomes pile body The effect of length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

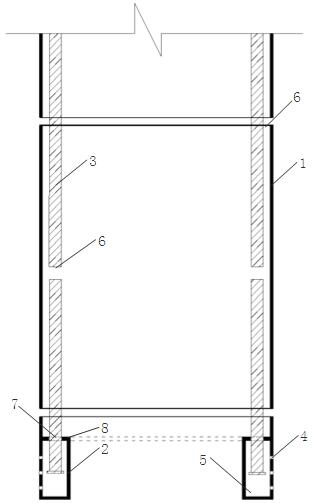

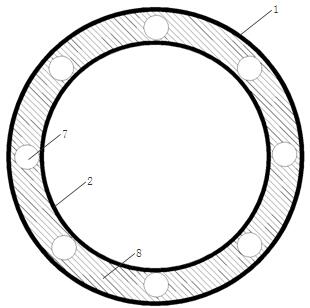

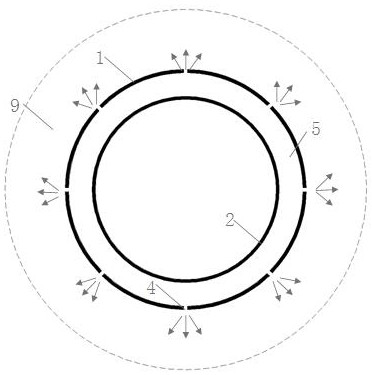

[0042] Step 1: On the basis of three connections and one leveling of the site, according to the data of the building survey control network and the foundation layout plan, determine the grid control network of the pile position axis and the elevation reference point, determine the center of the pile position, and take the center as the center of the circle , take the pile body radius plus the casing thickness as the radius to draw the circle of the upper part (that is, the first section), and the lime sprinkling line is used as the pile hole excavation dimension line, and four pile central axis controls are drawn out of the pile hole along the pile center position Points are marked with solid wooden stakes;

[0043] Step 2: Manual excavation of pile holes should be carried out layer by layer from top to bottom. First dig the middle part of the soil, and then expand to the surrounding area to effectively control the section size of the excavated pile holes. The height of each se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com