Composite cathode and preparation method thereof as well as application of composite cathode in biological electro-Fenton method

A composite cathode and mixed salt technology, which is applied in chemical instruments and methods, special compound water treatment, biological water/sewage treatment, etc., can solve the problems of rare catalysts, achieve excellent catalyst performance, wide pH adaptability, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Soak the carbon felt in concentrated nitric acid solution, oxidize at a constant temperature of 100°C for 2 hours, then rinse with water until the pH of the cleaning solution is neutral, and dry to constant weight.

[0035] Then dissolve 0.75 mmoL ferric chloride hexahydrate, 0.25 mmoL manganese sulfate monohydrate and 0.25 mmoL hexahydrate and cobalt chloride in 100 ml distilled water, stir to dissolve. The clean carbon felt modified by surface oxidation was immersed in the mixed salt solution of iron, manganese and cobalt, and ultrasonicated for 1 h.

[0036] 2) Slowly add 15mg / mL sodium borohydride aqueous solution dropwise at a rate of 0.5mL / s. While adding the reducing agent, shake the solution at a speed of 300rpm / min.

[0037] 3) The electrodes were left to stand, rinsed with water, and then dried in a vacuum oven at 50°C for 12 hours.

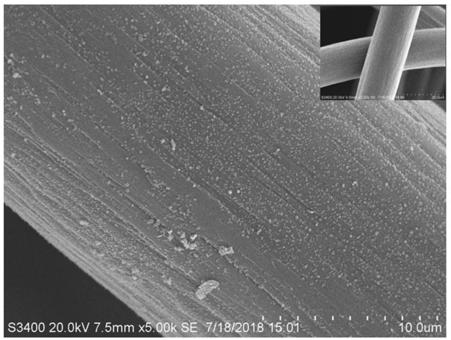

[0038] figure 1 For the SEM figure of the composite electrode that this embodiment 1 makes, by figure 1 It can be seen th...

Embodiment 2

[0040] 1) Soak the carbon felt in a concentrated nitric acid solution, oxidize it at a constant temperature of 80°C for 3 hours, then wash it with water until the pH of the cleaning solution is neutral, and dry it to a constant weight.

[0041] Then, dissolve 5mmoL ferric chloride hexahydrate, 2.5mmoL manganese sulfate monohydrate and 2.5mmoL cobalt chloride hexahydrate in 100ml distilled water, and stir to dissolve. The clean carbon felt modified by surface oxidation was immersed in the mixed salt solution of iron, manganese and cobalt, and ultrasonicated for 1 h.

[0042] 2) Slowly add 10mg / mL potassium borohydride aqueous solution dropwise at a rate of 0.1mL / s. While adding the reducing agent, shake the solution at a speed of 200rpm / min.

[0043] 3) The electrodes were left to stand, rinsed with water, and then dried in a vacuum oven at 40°C for 10 hours.

Embodiment 3

[0045] 1) Soak the carbon felt in a concentrated nitric acid solution, oxidize it at a constant temperature of 90°C for 1 hour, then wash it with water until the pH of the cleaning solution is neutral, and dry it to a constant weight.

[0046] Then 2.5mmol of ferric chloride hexahydrate, 2.5mmol of manganese chloride tetrahydrate and 2.5mmol of cobalt chloride hexahydrate were dissolved in 100mL of distilled water, and stirred to dissolve. The clean carbon felt modified by surface oxidation was immersed in the mixed salt solution of iron, manganese and cobalt, and ultrasonicated for 1 h.

[0047] 2) Slowly add 20 mg / mL hydrazine hydrate aqueous solution dropwise at a rate of 1 mL / s, and shake the solution at a speed of 250 rpm / min while adding the reducing agent.

[0048] 3) The electrodes were left to stand, rinsed with water, and then dried in a vacuum oven at 80°C for 5 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com