A kind of aqueous phase preparation method of maleic anhydride-conjugated diene copolymer

A technology of maleic anhydride and conjugated diene, which is applied in the field of aqueous phase preparation of maleic anhydride-conjugated diene copolymer, can solve the problems of environmental and human health impact, pollution and toxicity, and improve the reaction Efficiency, the effect of improving the induction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

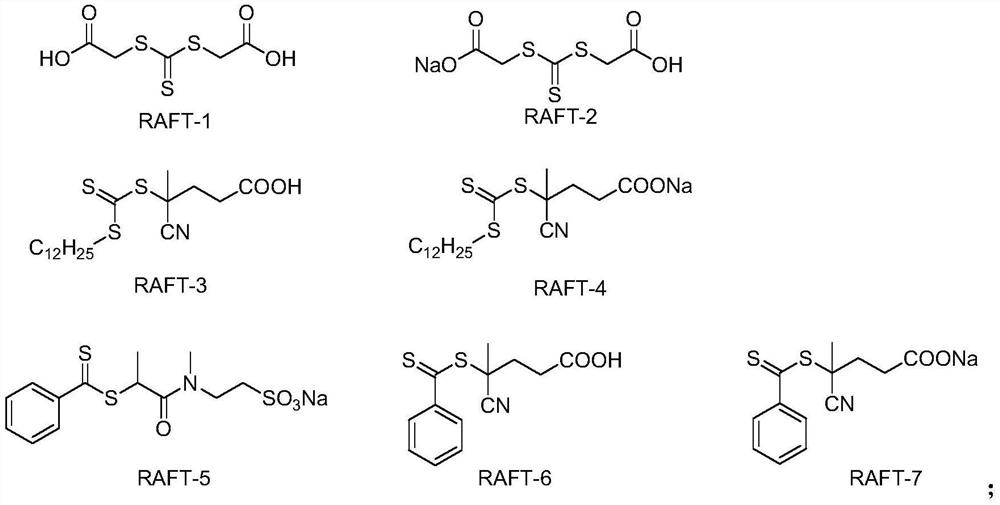

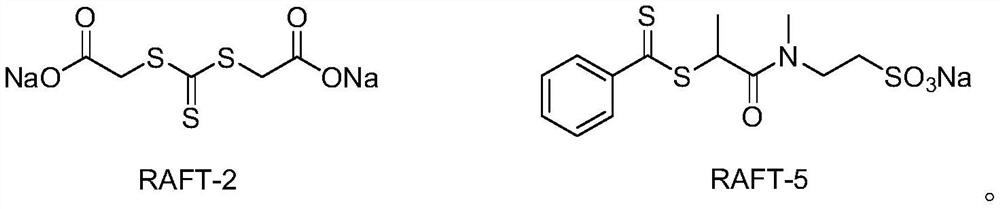

Method used

Image

Examples

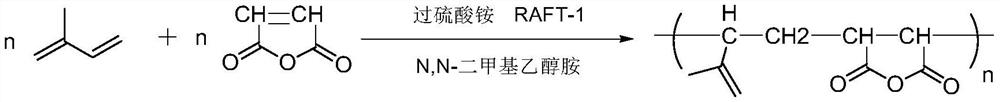

Embodiment 1

[0036]

[0037] Add 9.806g maleic anhydride, 0.304g RAFT-1, 0.108g N,N-dimethylethanolamine and 40.000g distilled water into the reactor and stir to dissolve; heat up to 60°C, slowly add 5.409g isoprene and 0.304 g ammonium persulfate initiator, stirred at a constant speed; after the dropwise addition, the temperature was raised to 95-100°C to continue the reaction for 2 hours; the temperature was lowered to room temperature, and the pH was adjusted to neutral with alkali to obtain an aqueous solution of maleic anhydride-isoprene copolymer. The viscosity average molecular weight is 19700, and the molecular weight distribution is 2.0.

Embodiment 2

[0039]

[0040] Add 9.806g maleic anhydride, 0.304g RAFT-5, 0.108g N,N-dimethylethanolamine and 40.000g distilled water into the reactor and stir to dissolve; heat up to 65°C, slowly add 5.409g isoprene and 0.304 g ammonium persulfate initiator, stirred at a constant speed; after the dropwise addition, the temperature was raised to 95-100°C to continue the reaction for 2 hours; the temperature was lowered to room temperature, and the pH was adjusted to neutral with alkali to obtain an aqueous solution of maleic anhydride-isoprene copolymer. The viscosity average molecular weight is 18000, and the molecular weight distribution is 1.8.

Embodiment 3

[0042]

[0043] Add 9.806g maleic anhydride, 0.304g RAFT-1, 0.108g pentaerythritol triacrylate and 40.000g distilled water into the reactor and stir to dissolve; heat up to 70°C, slowly add 5.409g isoprene and 0.304g ammonium persulfate Initiator, stir at a constant speed; after the dropwise addition, raise the temperature to 95-100°C to continue the reaction for 2 hours; cool down to room temperature, adjust the pH to neutral with alkali, and obtain an aqueous solution of maleic anhydride-isoprene copolymer with a viscosity-average molecular weight of 18,500 , molecular weight distribution 1.7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com