A high-temperature-resistant oil casing for hot steam injection heavy oil thermal recovery well and its manufacturing method

A technology for thermal recovery of heavy oil and oil casing, which is applied in the field of low-alloy oil casing steel and its production field, can solve the problems of low toughness, rare earth content without considering the welding problem, long heat preservation time, etc., and achieves high plastic toughness, The effect of shortening heat treatment time and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with specific embodiments.

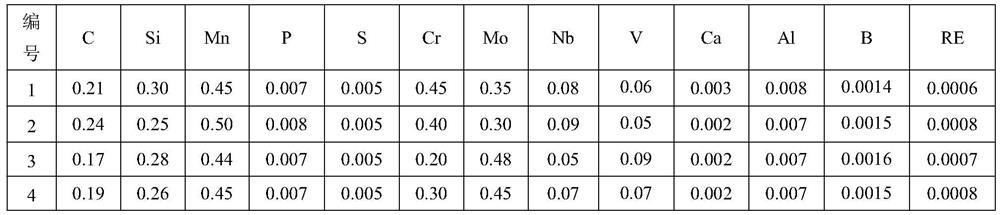

[0034] Raw materials were prepared according to the chemical composition in Table 1, and the weight percentages of the raw materials were: 80% of blast furnace molten iron and 20% of high-quality steel scrap.

[0035] Specific manufacturing process flow: molten iron pretreatment→top-bottom combined blowing converter smelting→LF furnace refining→VD vacuum treatment→slab continuous casting→controlled rolling into coils→steel strip slitting→FFX forming→HFW welding→hot stretching Diameter → sawing → online quenching → high temperature intermediate frequency heating and tempering → medium temperature tempering in the furnace → cooling bed → straightening → flaw detection → threading.

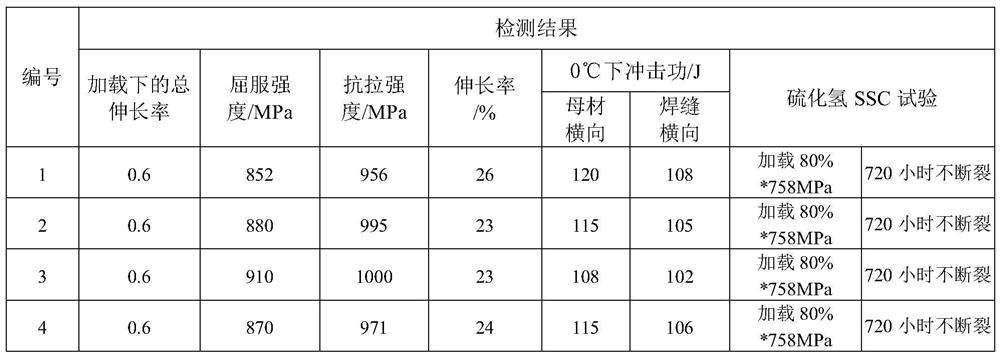

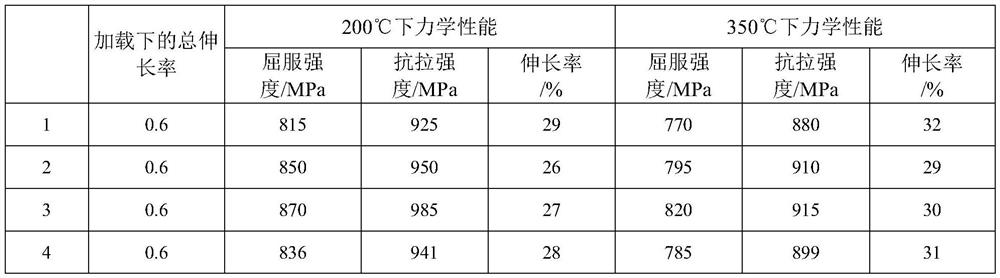

[0036]The results of the examples are shown in Table 1, Table 2, Table 3 and Table 4 below. Table 1 shows the smelting chemical composition of the test steel, Table 2 shows the mechanic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com