Polymer microsphere/endogenous microbial/biological surfactant ternary composite flooding type method for improving crude oil recovery efficiency of low-permeability oil reservoir

A technology of endogenous microorganisms and polymers, applied in drilling compositions, chemical instruments and methods, mining fluids, etc., can solve the problems of large radius of gyration of polymer molecules, waste of activators, loss and waste of activators, etc., to achieve The effect of enhancing oil recovery, increasing sweep coefficient, and improving oil washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

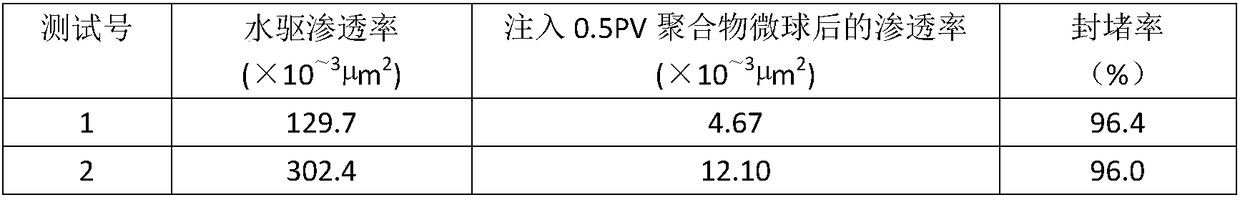

[0025] Example 1 Polymer Microsphere Swellability and Plugging Performance Test

[0026] (1) Experimental method: In the polymer microsphere expansion experiment, the polymer microspheres were added to the formation water, and a polymer microsphere solution with a mass concentration of 0.6% was prepared, stirred and dispersed for 30 minutes, and the dispersed solution was measured by a laser scattering particle size analyzer The primary particle size of the polymer microspheres. After aging for 20 days at 40°C, the particle size was measured.

[0027] In the plugging performance test of polymer microspheres, the polymer microspheres were added to the formation water to prepare a polymer microsphere solution with a mass concentration of 0.6%. After aging for 15 days at 40°C, a 25mm×500mm single sand-filled pipe was used to conduct the test. Blocking experiment. Under the condition of 40°C, first water flooding until the water cut reaches 98%, then inject 0.5PV polymer microsp...

Embodiment 2

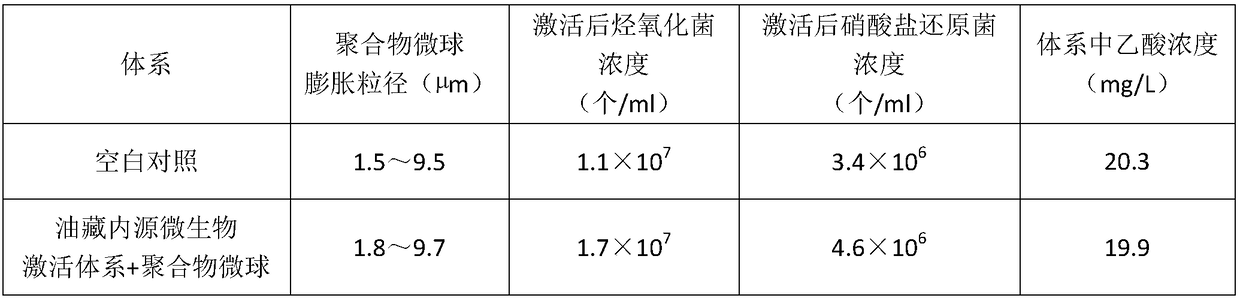

[0032] Example 2 Compatibility Test of Polymer Microspheres and Oil Reservoir Endogenous Microorganisms

[0033] (1) Preparation of oil reservoir endogenous microbial activator: prepare 10× endogenous microbial nutrient, yeast extract (industrial grade), molasses (industrial grade), sodium acid (industrial grade), rice milk dry powder (industrial grade) respectively added into the formation water, and mixed evenly so that the concentration of each component (by mass percentage) is 0.5%, 4%, 3%, and 4% respectively. Add 10×endogenous microbial nutrient into the oil well production fluid, so that its concentration (by mass percentage) is 10%.

[0034](2) Experimental method: Add polymer microspheres to the oil reservoir endogenous microbial activation system, the final concentration of polymer microspheres in the system is 0.6%, and the activation system without polymer microspheres is used as a blank control. Cultured at 40°C for 15 days. Detect the concentration of hydrocarb...

Embodiment 3

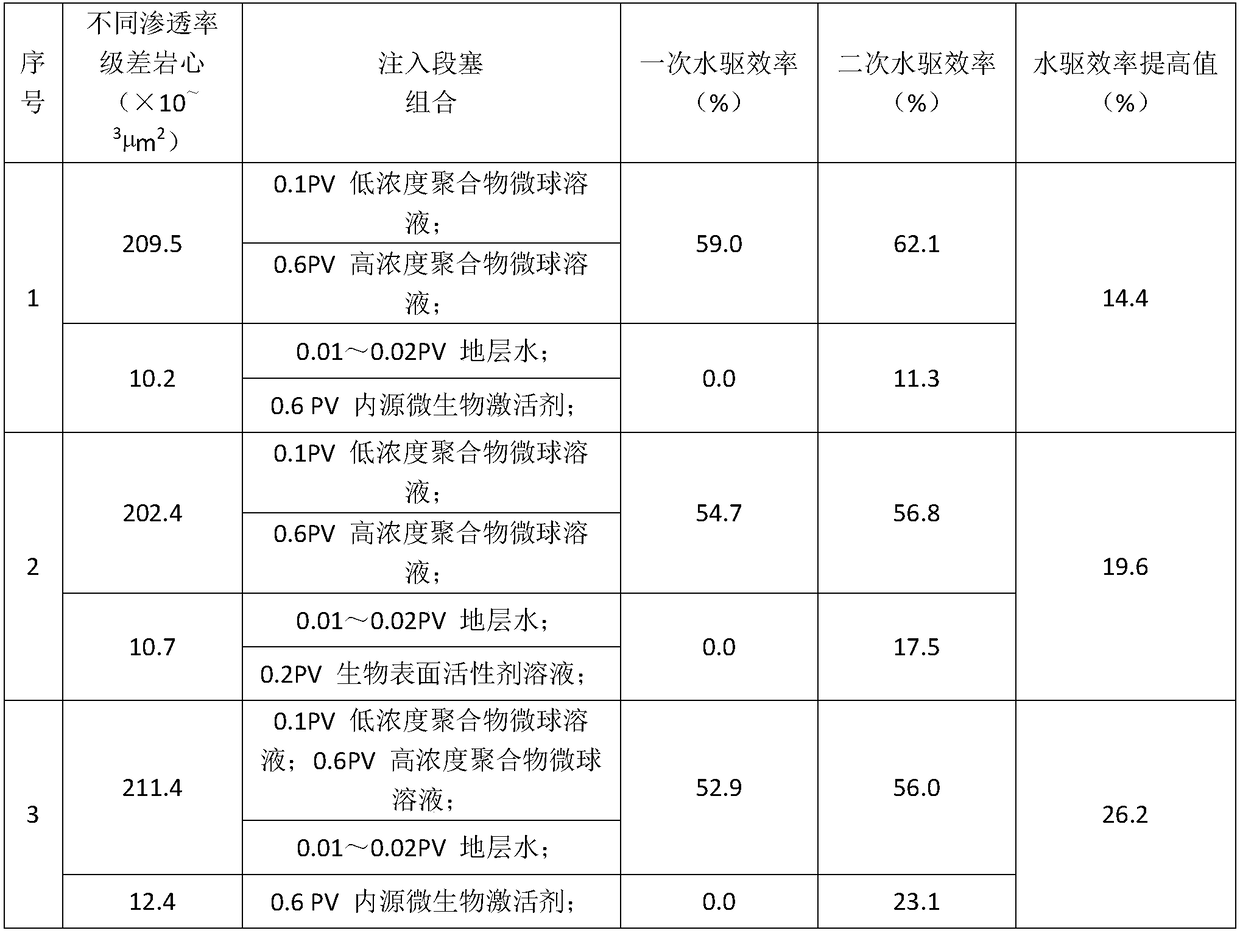

[0037] Example 3 Displacement experiment of the physical model of integral heterogeneous parallel sand filling pipes

[0038] (1) Polymer microsphere solution preparation: polymer microspheres were added to formation water to prepare polymer microsphere solutions with a mass concentration of 0.2% and 0.6%, respectively, and aged at 40° C. for 15 days.

[0039] (2) Preparation of oil reservoir endogenous microbial activator: as described in Example 1.

[0040] (3) Biosurfactant preparation: lipopeptide biosurfactant (industrial grade) and rhamnolipid (industrial grade) are added to formation water respectively, mix, make lipopeptide biosurfactant and rhamnose Lipid concentration (by mass percentage) is 20%.

[0041] (4) Experimental method: In a constant temperature box at 40°C, the average permeability is 106.8×10 ~3 μm 2 (Layered permeability is 204.8×10 ~3 μm 2 , 8.8×10 ~3 μm 2 ), 109.9×10 ~3 μm 2 (Layered permeability is 209.5×10 ~3 μm 2 , 10.2×10 ~3 μm 2 ), 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com