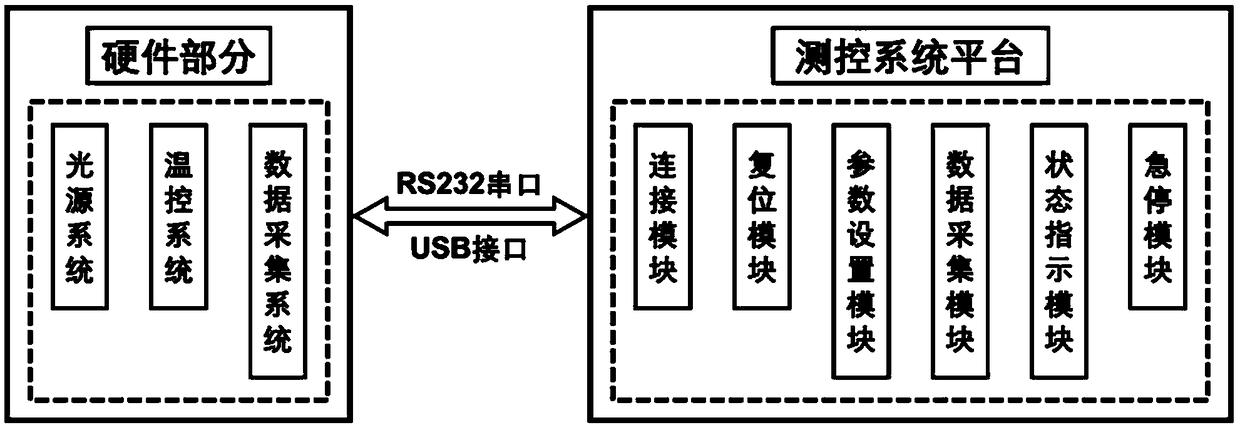

LabVIEW-based multi-functional optical test system and method

An optical testing and multi-functional technology, which is applied in general control systems, control/adjustment systems, and material analysis through optical means, can solve problems such as errors, unrealistic human operations, poor test stability and repeatability, etc., to improve Efficiency and reliability, reducing human error, and achieving the effect of programmed settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

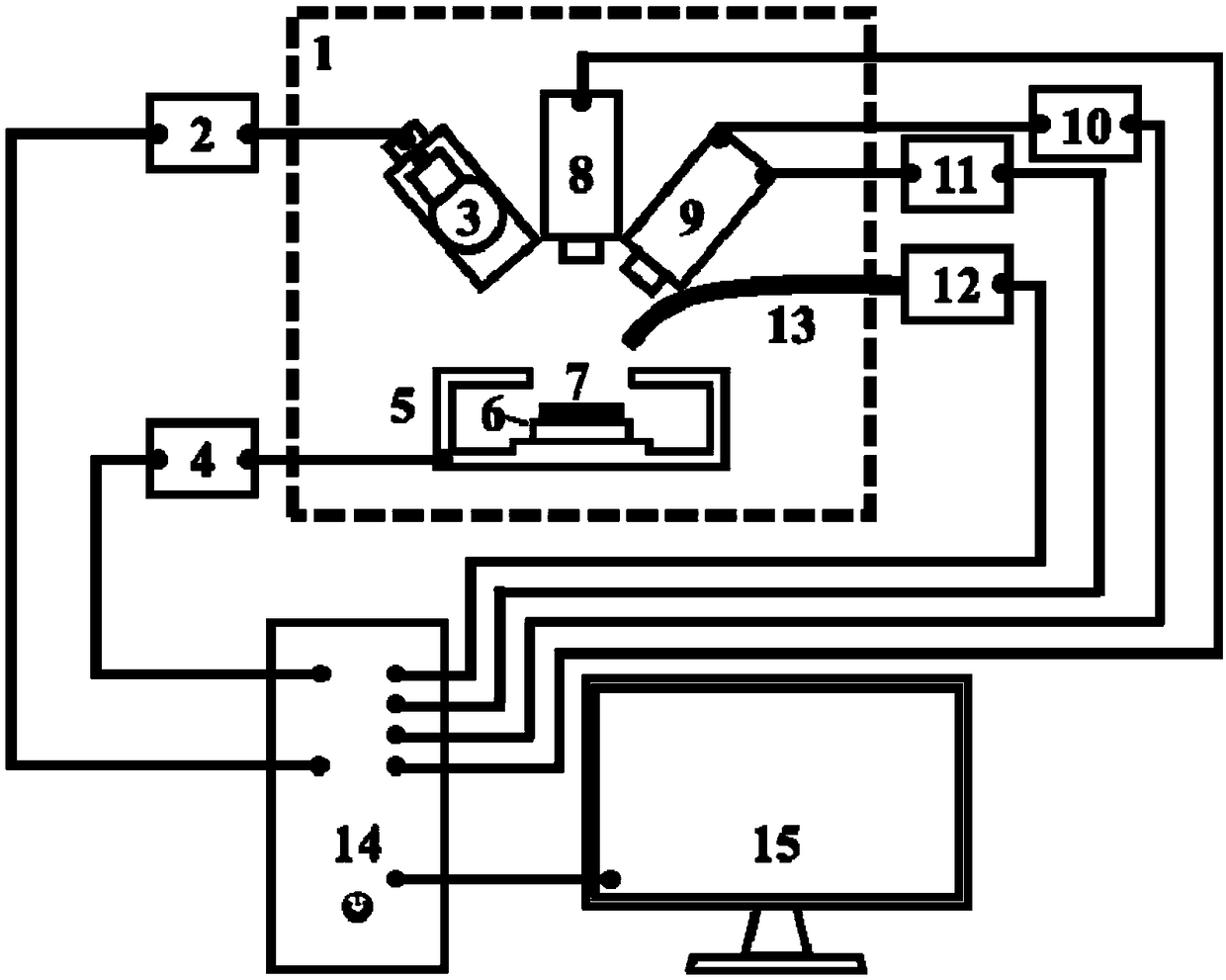

Method used

Image

Examples

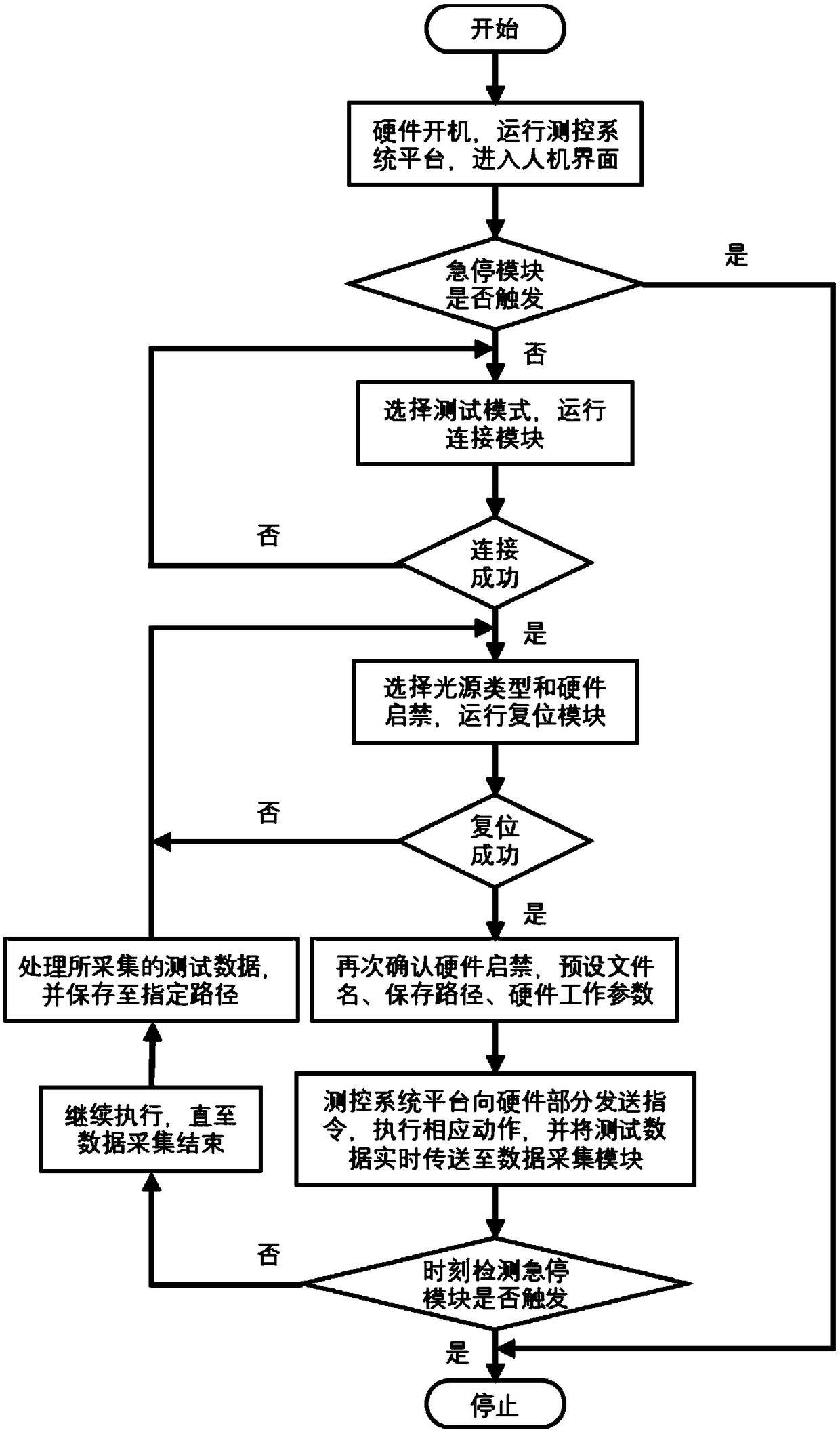

Embodiment 1

[0039] This is an example of long-lasting luminescence performance test. Run the measurement and control system platform, select the long afterglow test mode (the hot and cold stage is disabled by default), and run the connection module. Select the xenon lamp as the excitation light source, enable the dark field luminance meter, photomultiplier tube and fiber optic spectrometer, and run the reset module. The pop-up box reconfirms the hardware activation and prohibition, the preset file name and save path, the preset working voltage and working mode of the photomultiplier tube, and the background of the fiber optic spectrometer. After preset hardware working parameters, click the setting completion button to run the parameter setting module. Click the start button to run the test system: turn on the xenon lamp and wait for it to light up to excite the sample for about 12 seconds; turn off the xenon lamp after 30 seconds of excitation; after 2 seconds of stabilization, the dark ...

Embodiment 2

[0041] This is an example of a thermoluminescence performance test. Run the measurement and control system platform, select the thermoluminescence test mode (the dark field luminance meter is disabled by default), and run the connection module. Select the xenon lamp as the excitation light source, enable the hot and cold stage, photomultiplier tube and fiber optic spectrometer, and run the reset module. The pop-up box reconfirms the hardware activation and prohibition, the preset file name and save path, the preset working voltage and working mode of the photomultiplier tube, and the background of the fiber optic spectrometer. After preset hardware working parameters, click the setting completion button to run the parameter setting module. Click the start button to run the test system: the hot and cold stage drops to the excitation temperature of 280K at a rate of 50K / min and stabilizes for 18s; turn on the xenon lamp and wait for it to light up to excite the sample for about ...

Embodiment 3

[0043] This is an example of a constant temperature phosphorescent performance test. Run the measurement and control system platform, select the phosphorescence test mode (the dark field luminance meter and photomultiplier tube are disabled by default), and further set it to the constant temperature mode, and run the connection module. Select a suitable external excitation light source, enable the hot and cold stage and fiber optic spectrometer, and run the reset module. The pop-up box reconfirms the hardware activation and prohibition status, preset file name and save path, deducts the background of the fiber optic spectrometer, presets the hardware working parameters, and clicks the setting completion button to run the parameter setting module. Click the start button to run the test system: the cold and hot stage drops to the initial collection temperature of 200K at a rate of 50K / min, and after it stabilizes for 60s, the external light source is turned on to excite the samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com