Self-lubricating double-layer composite material and preparation method thereof

A composite material and self-lubricating layer technology, which can be applied to other household appliances, etc., can solve the problems of inability to meet the requirements of high-precision fit, complex manufacturing process, and binder toxicity, and increase manufacturing costs and energy consumption. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

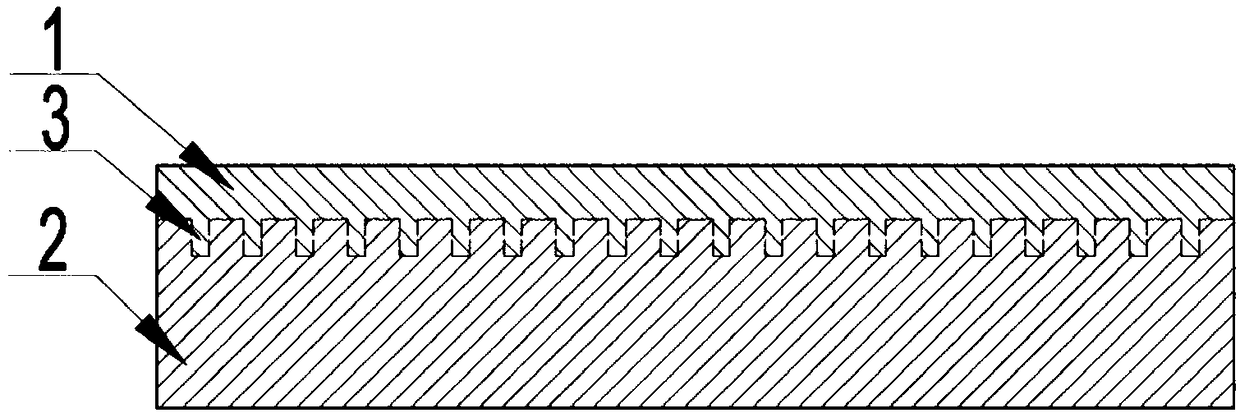

[0047] A self-lubricating double-layer gear pump side plate, using the self-lubricating double-layer composite material of the present invention, its structure also includes that the side plate has an "8" shape, and the thickness of the self-lubricating layer 2 is 0.15mm.

[0048] The metal base layer 1 is made of carbon steel plate, and the surface of the metal base plate is roughened by brushing and sandblasting.

[0049] The blind holes on the surface of the metal base layer 1 are blind holes 3 whose bottom area is larger than the area of the opening. The blind holes are evenly distributed on the metal base layer 1. The diameter of the blind holes is 1mm, the depth of the blind holes is 2mm, and the total surface area of the blind holes is 50% of the surface area of the metal matrix layer.

[0050] The polymer matrix in the self-lubricating layer 2 is polytetrafluoroethylene, and the additives in the self-lubricating layer include solid lubricant and wear-resistant ag...

Embodiment 2

[0063] A self-lubricating bearing uses the self-lubricating double-layer composite material of the present invention, and its structure further includes that the bearing is hollow cylindrical, and the thickness of the self-lubricating layer 2 is 0.03mm.

[0064] The metal base layer 1 is made of carbon steel plate, and the surface of the metal base plate is roughened by brushing and sandblasting.

[0065] The blind holes on the surface of the metal base layer are cylindrical blind holes 3, and the blind holes are evenly distributed on the metal base layer 1. The diameter of the blind holes is 0.5 mm, the depth of the blind holes is 0.5 mm, and the total surface area of the blind holes is 1 / 2 of the surface area of the metal base layer. 35%.

[0066] The polymer matrix in the self-lubricating layer 2 is polyether ether ketone. The additives in the self-lubricating layer include solid lubricant and anti-wear agent, and the solid lubricant is graphite; the anti-wear agent is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com