A kind of modified cotton fiber adsorbent for removing nitrate nitrogen and its preparation method and application

A technology for modifying cotton and nitrate nitrogen, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of inability to adsorb nitrate well, small adsorption capacity, poor adsorption effect, etc. , to achieve the effect of large production, improved adsorption effect and reduced interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

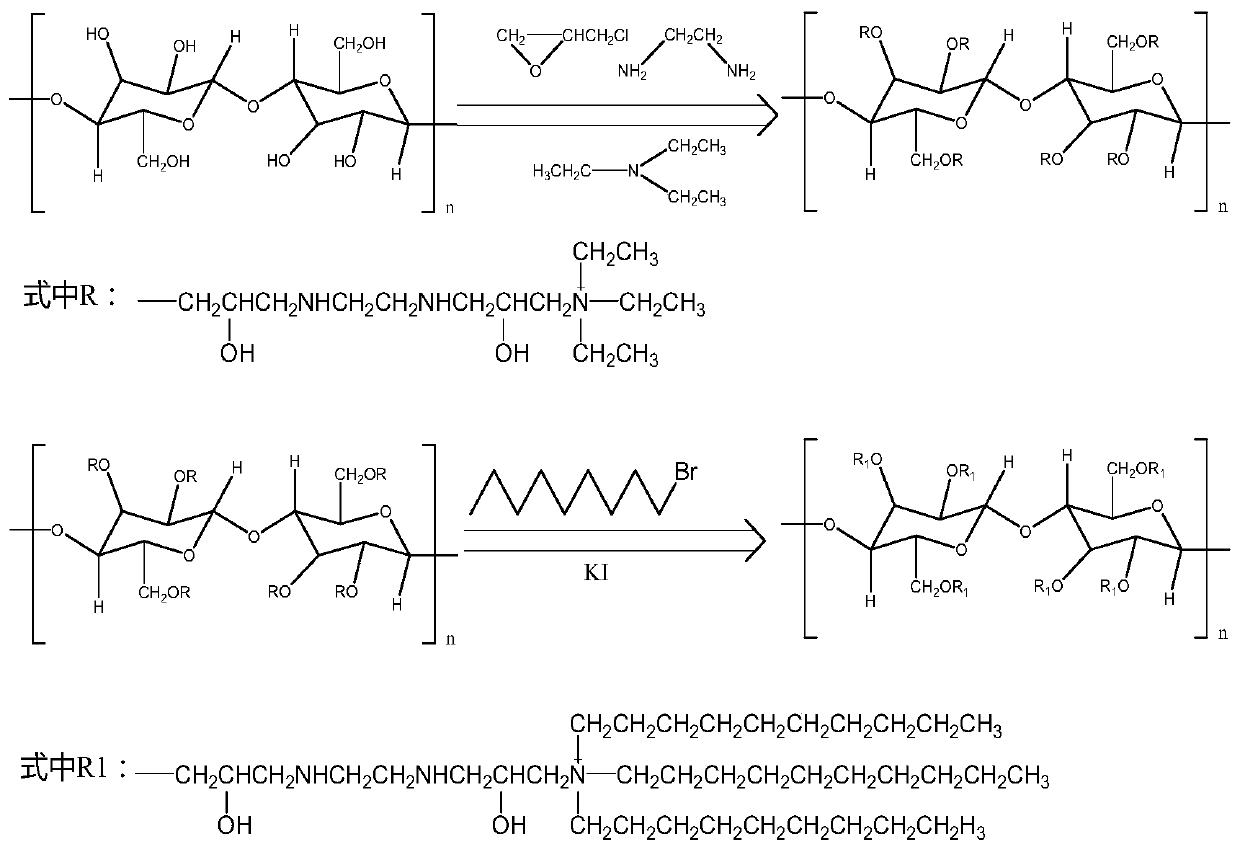

[0022] The invention provides a kind of preparation method of the modified cotton fiber adsorbent for removing nitrate nitrogen, comprising the following steps:

[0023] Refining cotton fibers to obtain refined cotton fibers;

[0024] Mixing the refined cotton fiber, N,N-dimethylformamide and epichlorohydrin for an etherification reaction to obtain an etherification product;

[0025] Mixing the etherification product, ethylenediamine and triethylamine for a nucleophilic substitution reaction to obtain a nucleophilic substitution product;

[0026] The nucleophilic substitution product, potassium iodide and brominated n-decane are mixed for alkylation reaction to obtain a modified cotton fiber adsorbent for removing nitrate nitrogen.

[0027] The invention refines the cotton fiber to obtain the refined cotton fiber. In the present invention, the source of the cotton fiber is not particularly limited, and commercially available products or discarded cotton products well known t...

Embodiment 1

[0046] Soak and clean the waste cotton fiber in deionized water to remove dust and impurities on the surface, then put it into a constant temperature drying box, dry it at 60°C for 12 hours, pulverize it with a pulverizer, and pass through a 120-mesh sieve to obtain cotton fiber powder. Put it into a beaker containing NaOH (0.05mol / L), and magnetically stir it at 60°C for 4 hours to remove cellulose impurities in cotton products, then wash it with deionized water three times, and then put it in a constant temperature drying oven to dry at 60°C 2h, take out 2g of the obtained refined cotton fiber and put it into a three-neck round bottom flask, add epichlorohydrin as a crosslinking agent, N,N-dimethylformamide (DMF) 10mL as a solvent, and heat at 90°C for 1h After reaction, 3 mL of ethylenediamine was added and stirred and heated at 90° C. for 1 h. Then add 6 mL of triethylamine (99%) solution, stir and heat at 90° C. for 1.5 h, modify the cellulose on the cotton fiber, introdu...

Embodiment 2

[0050] Soak and clean the cotton products in deionized water to remove dust and impurities on the surface, then put them into a constant temperature drying oven, dry them at 70°C for 12 hours, and then pass them through a 100-mesh sieve through a pulverizer to crush the cotton fibers The powder was put into a beaker containing NaOH (0.1 mol / L), magnetically stirred at 45°C for 6h, washed with deionized water three times, and dried in a constant temperature drying oven at 60°C for 4h. After drying, put it into a three-necked round bottom flask, add epichlorohydrin as a crosslinking agent, DMF as a solvent, and heat at 90°C for 1h to react; then add ethylenediamine and stir and heat at 90°C for 1h; add three Ethylamine (99%) solution was stirred and heated at 90°C for 1.5h, and the mass volume ratio of the mass of cotton fiber added, DMF, ethylenediamine, and triethylamine was 2g:10mL:3mL:6mL. Wash the unreacted organic matter on the surface with absolute ethanol, and put it int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com