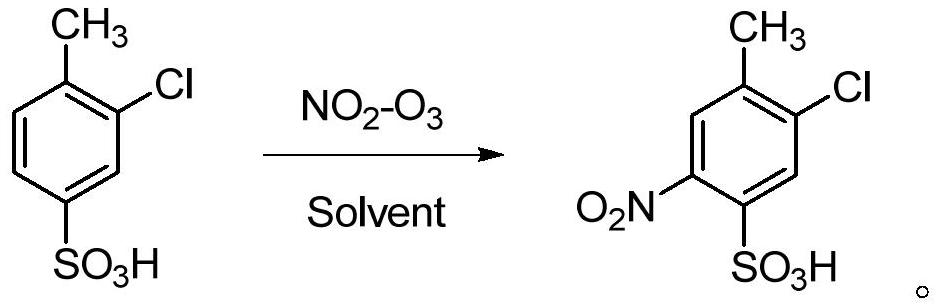

Method and device for pipelined preparation of 2-nitro-5-chloro-4-methylbenzenesulfonic acid

A technology of toluenesulfonic acid and toluenesulfonic acid, which is applied in the field of tubular nitration, can solve the problems of poor selectivity and achieve the effects of simple operation, simple post-treatment, and rapid mass and heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

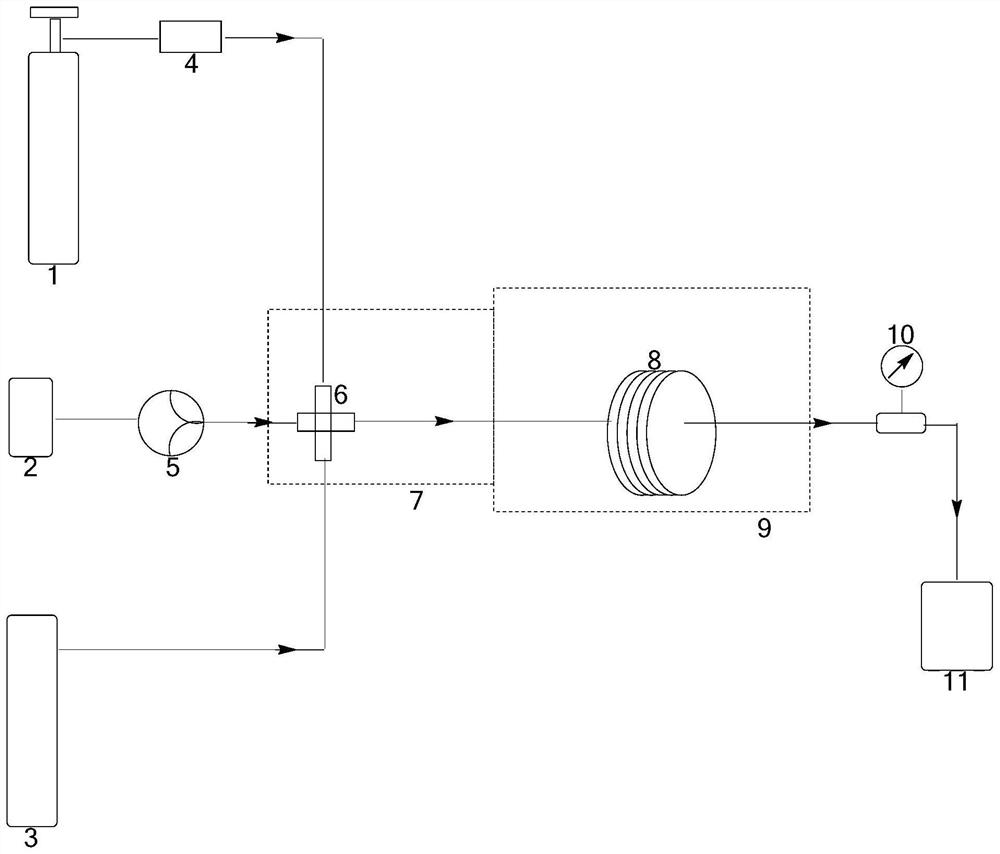

[0042] The structure of the reaction device is as figure 1 , the length 8 of the reaction pipeline after the inner coating of alumina is 20m, the inner diameter is 4.3mm, and the outer diameter is 6.3mm. The material of the pipeline is corrosion-resistant and high-pressure resistant metal material, which is Hastelloy C-276.

[0043] The operation steps are as follows:

[0044] First connect the device, check the tightness; dissolve the raw material 3-chloro-4-toluenesulfonic acid in the organic solvent methylene chloride, and its volumetric dosage is 8mL / g based on the quality of the raw material 3-chloro-4-toluenesulfonic acid, Add storage tank 2; turn on the cooling system 7 to cool down the cross-type mixing joint 6 to -5~5°C; turn on the heating system 9 to preheat the reaction pipeline 8 that has passed the inner coating of alumina to the reaction temperature of 25°C; turn on the ozone generator 3 , set the ozone flow, adjust the back valve 10, so that the pressure in th...

Embodiment 2

[0046] The structure of the reaction device is as figure 1 , the length 8 of the reaction pipeline after the inner coating of alumina is 25m, the inner diameter is 4.3mm, and the outer diameter is 6.3mm. The material of the pipeline is corrosion-resistant and high-pressure resistant metal material, which is Hastelloy C-276.

[0047] The volumetric amount of dichloromethane is 10mL / g based on the mass of the raw material 3-chloro-4-toluenesulfonic acid, the reaction temperature is 40°C, the pressure in the reaction pipeline 8 is maintained at 0.6MPa, and the 3-chloro-4-toluenesulfonic acid The molar ratio of acid to nitrogen dioxide is 1:1.8, and the reaction residence time is 20min. Other operations are the same as in Example 1. The product was obtained after post-treatment with a yield of 85% and a purity of 99.2% as detected by HPLC.

Embodiment 3

[0049] The structure of the reaction device is as figure 1 , the length 8 of the reaction pipeline after the inner coating of alumina is 30m, the inner diameter is 4.3mm, and the outer diameter is 6.3mm. The material of the pipeline is corrosion-resistant and high-pressure resistant metal material, which is Hastelloy C-276.

[0050] The volumetric amount of dichloromethane is 12mL / g based on the mass of the raw material 3-chloro-4-toluenesulfonic acid, the reaction temperature is 30°C, the pressure in the reaction pipeline 8 is maintained at 0.8MPa, and the 3-chloro-4-toluenesulfonic acid The molar ratio of acid to nitrogen dioxide is 1:1.6, and the reaction residence time is 30min. Other operations are the same as in Example 1. The product was obtained after post-treatment with a yield of 92% and a purity of 99.4% as detected by HPLC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com