Municipal solid waste incineration bottom ash modified polyurethane-epoxy resin interpenetrating polymer network composite material and preparation method thereof

A technology for incineration of domestic waste and interpenetrating polymers is applied in the field of interpenetrating polymer network materials and their preparation, which can solve the problems of brittleness and poor impact performance of cured products, and achieve the improvement of mechanical properties and thermal stability, and the price is excellent and cheap. , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

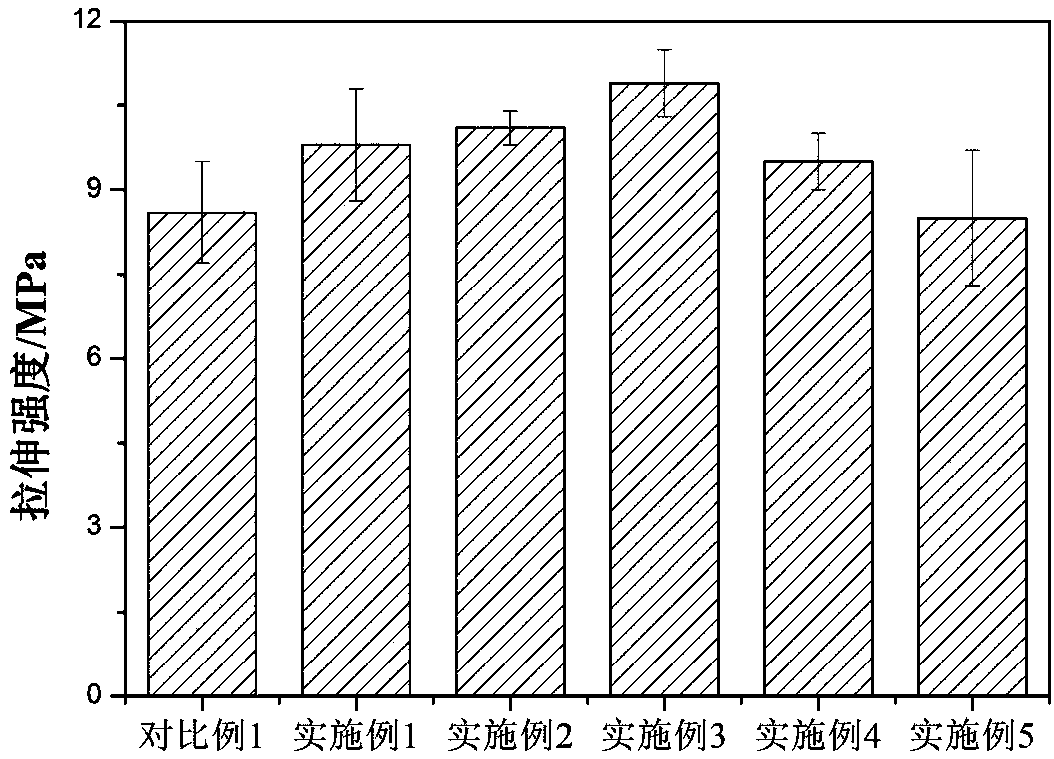

Embodiment 1

[0030]Step 1: Weigh 0.15 kg of weathered municipal solid waste incineration bottom ash, mix it with 300 mL of distilled water, ultrasonicate for 1 h (with a power of 250 W), filter, and dry for 12 h. Then the bottom ash was ball-milled until the particle size was less than 200 mesh, and the washed bottom ash was obtained; 0.1 kg of the washed bottom ash was weighed, mixed with 1000 mL of 1 mol / L hydrochloric acid, and ultrasonicated for 90 minutes at room temperature (power 250W). After acid activation, wash with water until neutral, then wash with acetone, dry the filter cake in vacuum at 120°C for 12 hours, and grind to obtain the pickled bottom ash; weigh 50g of the pickled bottom ash, and mix with 100g of isophorone Diisocyanate, 25g tetrahydrofuran, reflux at 70-80°C for 3-4 hours, filter, vacuum-dry the filter cake at 120°C for 12 hours, and grind to obtain the bottom ash modified by isophorone diisocyanate.

[0031] Step 2: Take 1.01 g of the bottom ash modified by isop...

Embodiment 2

[0036] Step 1: prepare the bottom ash after isophorone diisocyanate modification with reference to the method of embodiment 1;

[0037] Step 2: Take 5.1 g of bottom ash modified with isophorone diisocyanate, mix it with tetrahydrofuran at a mass ratio of 1:3, and ultrasonicate at room temperature for 1 hour (power 250W) to obtain a bottom ash suspension.

[0038] Step 3: Take 65.09g of castor oil and 9.91g of isophorone diisocyanate, mix them, and stir at 90°C for 1 hour to form a polyurethane prepolymer based on castor oil.

[0039] Step 4: After the prepolymer is cooled to room temperature, mix it with 132.58g epoxy resin, add the bottom ash suspension to the polyurethane-epoxy resin mixture, stir for 2-3 hours with a magnet, and remove tetrahydrofuran at 70°C. Then add 42.42g of curing agent D230, stir, ultrasonic for 30min (power is 250W), vacuum defoaming, curing at 90°C for 2h, curing at 110°C for 3h, to obtain municipal solid waste incineration bottom ash modified polyu...

Embodiment 3

[0042] Step 1: prepare the bottom ash after isophorone diisocyanate modification with reference to the method of embodiment 1;

[0043] Step 2: Take 9.28g of the bottom ash modified by isophorone diisocyanate, mix it with tetrahydrofuran at a mass ratio of 1:3, and ultrasonicate at room temperature for 1 hour (with a power of 250W) to obtain a bottom ash suspension.

[0044] Step 3: Mix 78.1 g of castor oil with 11.9 g of isophorone diisocyanate, and stir at 90° C. for 1 hour to form a polyurethane prepolymer based on castor oil.

[0045] Step 4: After the prepolymer is cooled to room temperature, mix it with 159.09g of epoxy resin, add the bottom ash suspension to the polyurethane-epoxy resin mixture, stir for 2-3 hours with a magnet, and remove tetrahydrofuran at 70°C. Then add 50.91g of curing agent D230, stir, ultrasonic for 30min (power is 250W), vacuum defoaming, curing at 90°C for 2h, curing at 110°C for 3h, to obtain municipal solid waste incineration bottom ash modifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com