A kind of graphene/chitosan composite material and preparation method thereof

A composite material and graphene technology, applied in the field of composite materials, can solve the problems of rough appearance of electrodeposited layer, uneven and smooth surface, low graphene content, etc., to achieve enhanced thermal stability and mechanical properties, simple equipment, and good biological properties. Compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

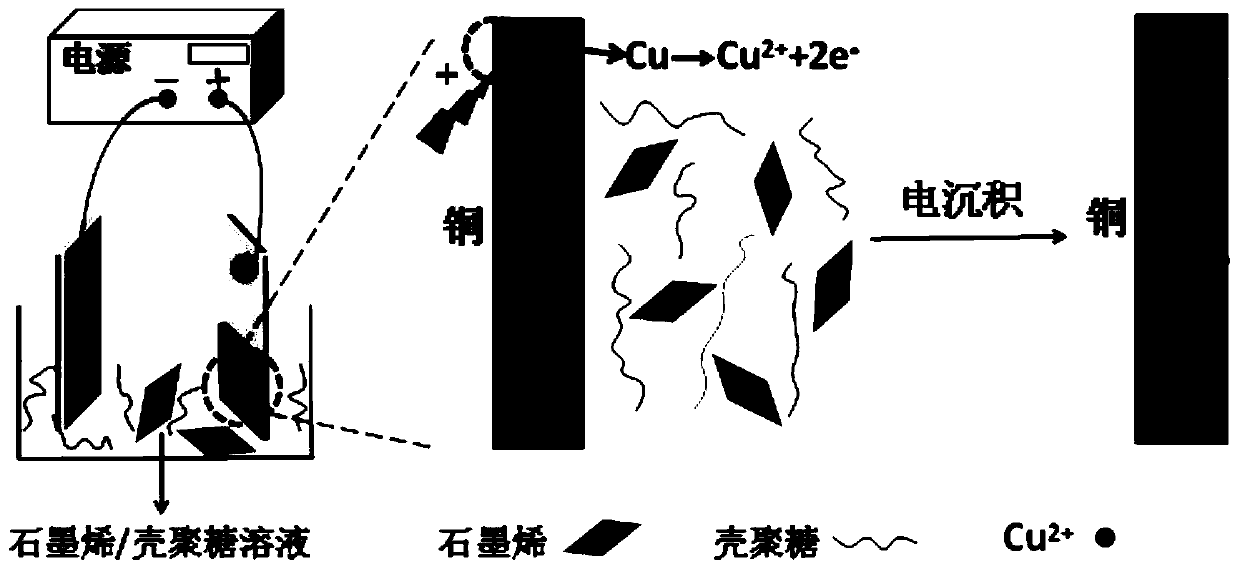

[0028] The graphene / chitosan composite material is prepared by anodic electrodeposition technology, and the steps are as follows:

[0029] 1) Preparation of graphene dispersion: Weigh 0.1g of graphite oxide, add it to a beaker filled with 40mL of 0.05M aqueous sodium hydroxide solution, and obtain a graphene oxide dispersion (mass concentration of 2.5mg / mL) through ultrasonic dispersion for 10 minutes ); Take 0.3g chitosan quaternary ammonium salt and join in the beaker that fills 100mL distilled water, through magnetic stirring 1 hour, obtain chitosan quaternary ammonium salt aqueous solution (mass concentration is 3mg / mL); Then the above-mentioned obtained The graphene oxide dispersion was added to the chitosan quaternary ammonium salt solution for mixing, stirred magnetically at room temperature for 1 hour to obtain a mixed solution, then adjusted the pH value of the mixed solution to 11 with 0.07M aqueous sodium hydroxide solution, and then mixed 0.4g Hydrazine hydrate was...

Embodiment 2

[0036] The graphene / chitosan composite material is prepared by anodic electrodeposition technology, and the steps are as follows:

[0037] 1) Preparation of graphene dispersion: Weigh 0.2g of graphite oxide, add it to a beaker filled with 80mL of 0.05M sodium hydroxide aqueous solution, and obtain a graphene oxide dispersion with a mass concentration of 2.5mg / mL after ultrasonic dispersion for 50 minutes Take by weighing 1.0g chitosan quaternary ammonium salt and join in the beaker that fills 200mL distilled water, through magnetic stirring 5 hours, obtain the chitosan quaternary ammonium salt aqueous solution that mass concentration is 5mg / mL; Then the above-mentioned graphite oxide obtained Add the ethylene dispersion to the chitosan quaternary ammonium salt solution for mixing, stir magnetically at room temperature for 5 hours to obtain a mixed solution, then adjust the pH value of the mixed solution to 10 with 0.05M aqueous sodium hydroxide solution, and then add 1.1g of hy...

Embodiment 3

[0044] The graphene / chitosan composite material is prepared by anodic electrodeposition technology, and the steps are as follows:

[0045] 1) Preparation of graphene dispersion: Weigh 0.2g of graphite oxide, add it to a beaker filled with 40mL of 0.05M aqueous sodium hydroxide solution, and obtain a graphene oxide dispersion with a mass concentration of 5mg / mL through ultrasonic dispersion for 30 minutes; Take by weighing 1.0g chitosan quaternary ammonium salt and join in the beaker that fills 200mL distilled water, through magnetic stirring 3 hours, obtain the chitosan quaternary ammonium salt aqueous solution that mass concentration is 5mg / mL; Then the graphene oxide obtained above Add the dispersion to the chitosan quaternary ammonium salt solution for mixing, stir magnetically at room temperature for 2 hours to obtain a mixed solution, then adjust the pH value of the mixed solution to 9 with 0.03M aqueous sodium hydroxide solution, and then drop 0.8g hydrazine hydrate Add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com