A heat-insulating fireproof coating and its preparation process

A fire-resistant coating and coating technology, applied in the direction of fire-resistant coatings, coatings, epoxy resin coatings, etc., to achieve the effects of good insulation, heat insulation and fire resistance, good protection effect, and strong bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] 1.1 Preparation of coating

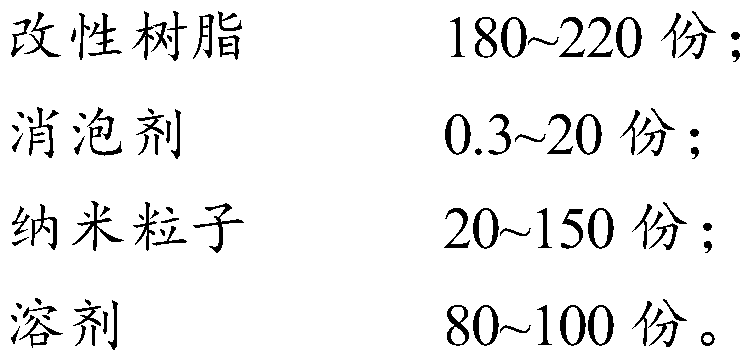

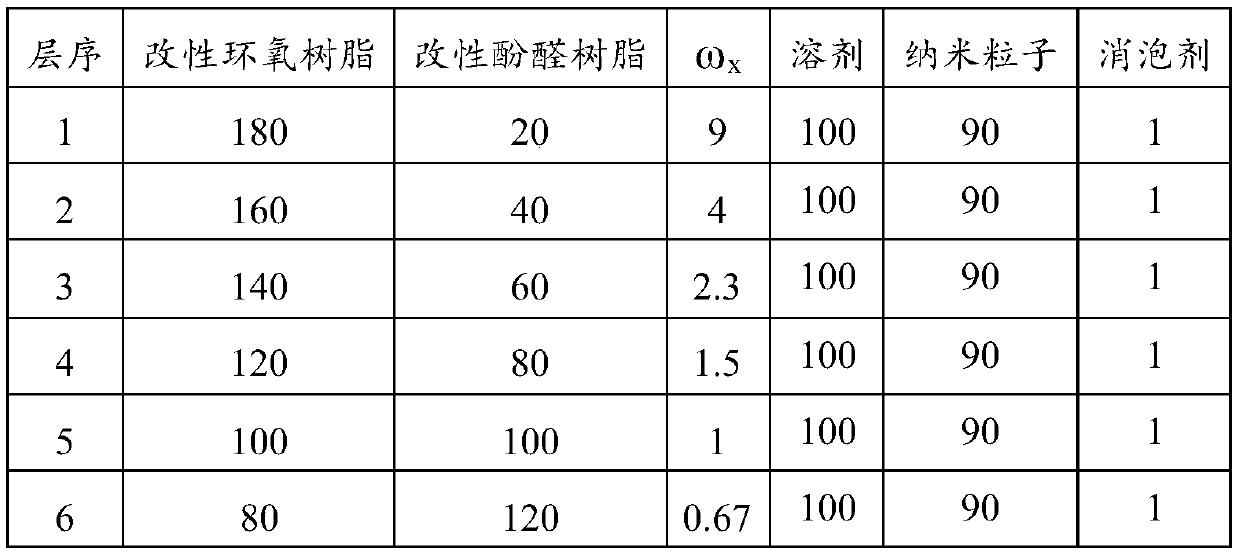

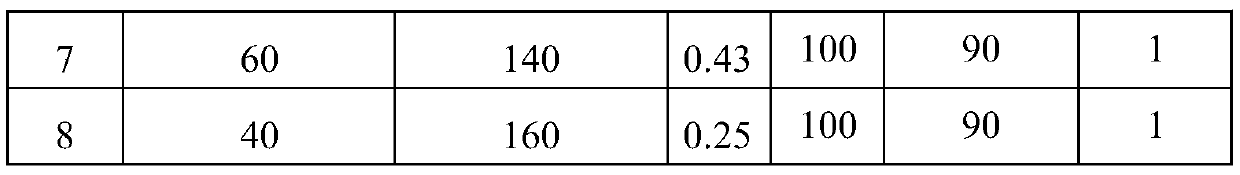

[0079] The fireproof coating consists of 8 layers, and the material composition of each layer of coating is as follows: silicone modified epoxy resin (viscosity is 900mPa.s, model is ES531), silicone modified phenolic resin (viscosity is 3000mPa.s, model is PFS6410), absolute ethanol solvent, polyether modified silicone defoamer (model is Tokuda X634), boron carbide nanoparticles with an average diameter of 200nm. The component contents of different layers are shown in Table 1, and the content units of each component in Table 1 are parts by mass.

[0080] Based on epoxy resin and carbon fiber cured oxygen tank-shaped parts (provided by Carben Carbon Fiber Technology (Dongguan) Co., Ltd., the short-term heat resistance temperature does not exceed 300°C), the coating is cured by uniform heating after layer-by-layer spraying , the average thickness of each layer is 0.1mm; the gradient heating process is as follows: first heat up to 50°C for 8 ...

Embodiment 2

[0091] 1.1 Preparation of coating

[0092] The fireproof coating consists of 8 layers, and the material composition of each layer of coating is as follows: polyether modified epoxy resin (viscosity is 1000mPa.s, model is EP-4000), silicone modified phenolic resin (viscosity is 3000mPa.s, Model is PFS6410), absolute ethanol solvent, polydimethylsiloxane defoamer (model is BYK-R605), boron nitride nanoparticles with an average diameter of 250nm. The component content of different layers is shown in Table 2, and the content unit of each component in Table 2 is parts by mass.

[0093] Based on epoxy resin and carbon fiber cured oxygen tank-shaped parts (provided by Carben Carbon Fiber Technology (Dongguan) Co., Ltd., the short-term heat resistance temperature does not exceed 300°C), the coating is cured by uniform heating after layer-by-layer spraying , the average thickness of each layer is 0.1mm; the gradient heating process is as follows: first heat up to 50°C for 8 hours, the...

Embodiment 3

[0104] 1.1 Preparation of coating

[0105] The fireproof coating consists of 7 layers, and the material composition of each layer of coating is as follows: silicone modified epoxy resin (viscosity is 900mPa.s, model is ES531), polyamide modified phenolic resin (viscosity is 4000mPa.s, model is Japan Chisso company E type), ethylene glycol dimethyl ether solvent, polydimethylsiloxane defoamer (model is BYK-R605), and the average diameter is the boron carbide nano-particle of 150nm. The component content of different layers is shown in Table 3, and the content unit of each component in Table 3 is parts by mass.

[0106] Based on epoxy resin and carbon fiber cured oxygen tank-shaped parts (provided by Carben Carbon Fiber Technology (Dongguan) Co., Ltd., the short-term heat resistance temperature does not exceed 300°C), the coating is cured by uniform heating after layer-by-layer spraying , the average thickness of each layer is 0.15mm; the gradient heating process is as follows:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com