Waterborne epoxy anticorrosive coating and preparation method thereof

A water-based epoxy and anti-corrosion coating technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor marine heavy-duty anti-corrosion effect, unsatisfactory anti-corrosion effect, and oxidative aging of coatings, so as to improve the overall anti-corrosion performance, improve the protective compactness, and maintain the effect of tight adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

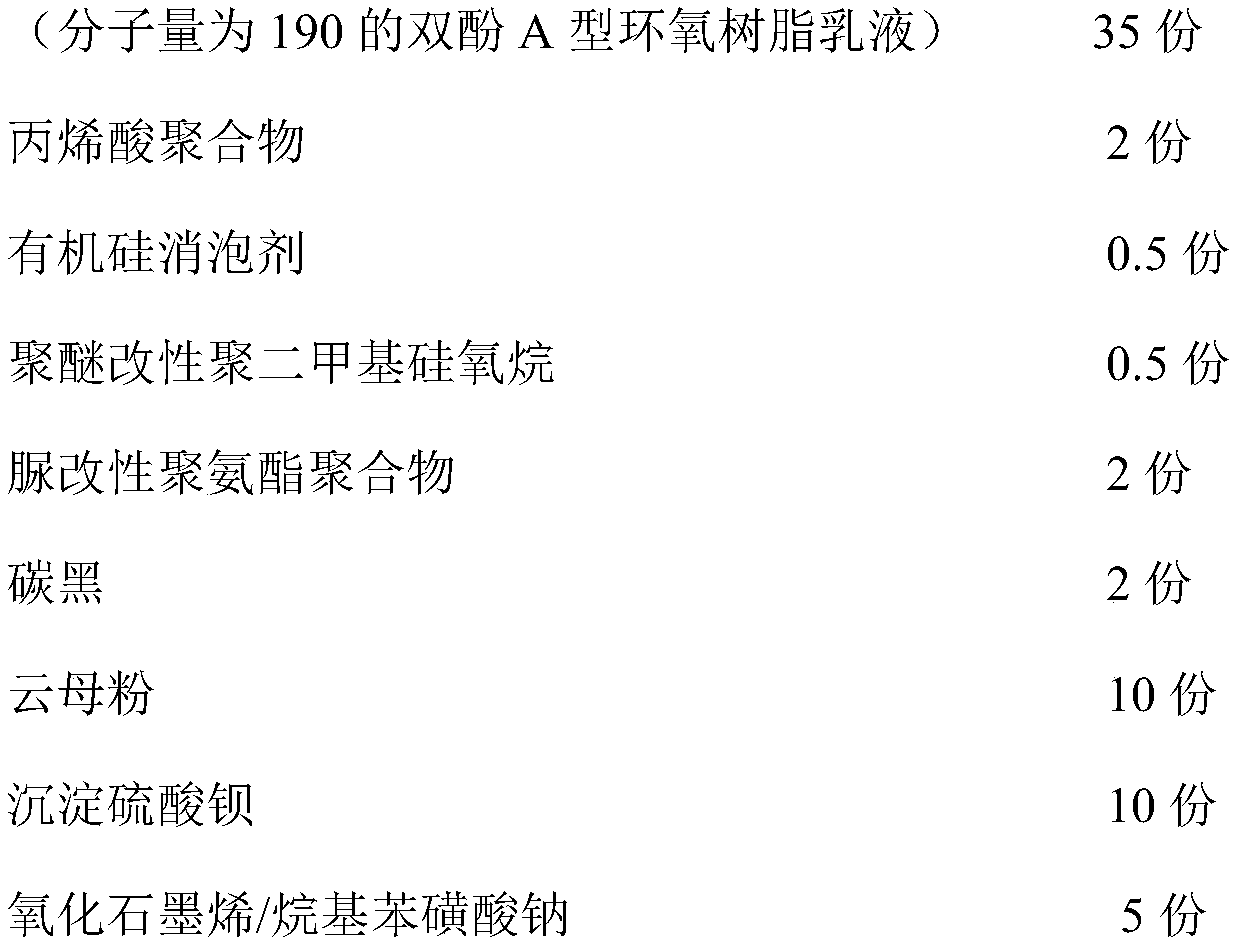

[0025] Component A:

[0026] Waterborne Epoxy Emulsion

[0027]

[0028]

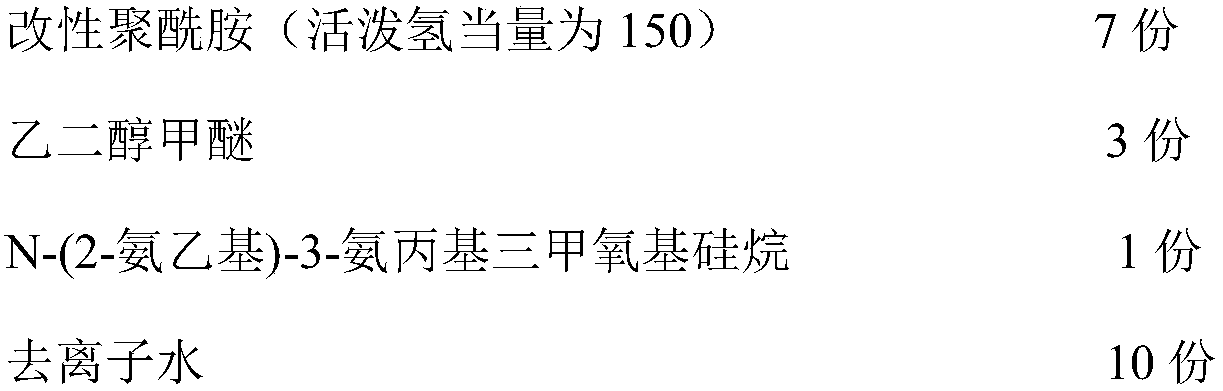

[0029] Component B:

[0030]

[0031] According to the mass ratio, component A: component B = 3:1 mixed to prepare water-based epoxy anticorrosion coating.

[0032] The preparation of described graphene oxide / sodium alkylbenzene sulfonate is to mix graphene oxide and sodium alkylbenzene sulfonate in a mass ratio of 1:9 to obtain 100g of the mixture, which is put into 200g of methanol and stirred for 2h with magnetic force, during which Add a total amount of 1% boric acid, move to an ultrasonic vibration disperser for 2 hours, and distill off methanol under reduced pressure to obtain graphene oxide / sodium alkylbenzene sulfonate. The graphene oxide / alkylbenzene sulfonates in the following examples are all prepared by this method.

[0033] The preparation method of the water-based epoxy anti-corrosion coating of the present invention is as follows: in the state of stirring, firstly mix the acry...

Embodiment 2

[0035] Component A:

[0036] Waterborne Epoxy Emulsion

[0037]

[0038]

[0039] Component B:

[0040]

[0041] According to the mass ratio, component A: component B = 4:1 mixed to prepare water-based epoxy anticorrosion paint.

Embodiment 3

[0043] Component A:

[0044] Waterborne Epoxy Emulsion

[0045]

[0046] Component B:

[0047]

[0048]

[0049] According to the mass ratio, component A: component B = 5:1 mixed to prepare water-based epoxy anticorrosion coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com