A kind of aluminum ash processing method

A processing method and technology for aluminum ash, applied in the direction of improving process efficiency, can solve problems such as impact, waste of aluminum resources, environmental problems, etc., and achieve the effects of reducing environmental pollution, reducing pollution, and reducing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

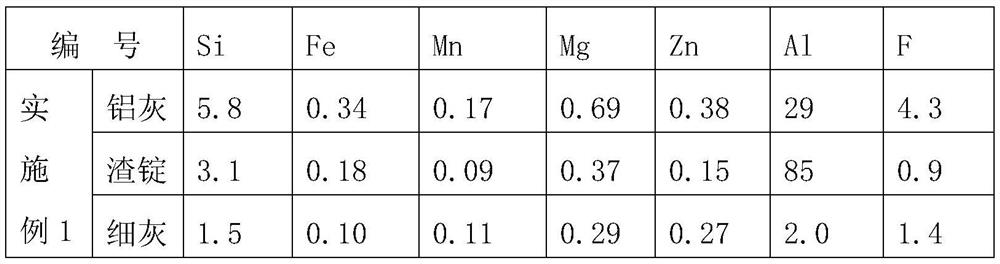

Embodiment 1

[0029] S1: Using crushed water hyacinth powder as carbon source and corn flour as nitrogen source, Streptococcus mutans ua159 was cultured, wherein the mass ratio of water hyacinth powder to corn flour was 1:1, and the culture temperature was 20°C.

[0030] S2: Pour the aluminum ash into a culture tank containing a large amount of mutans streptococcus, and add sodium sulfate to it, the mass ratio of sodium sulfate to aluminum ash is 1:30, after stirring evenly, use mutans streptococcus to treat the aluminum ash for 15 Hour.

[0031] S3: Take out the processed aluminum ash, drain it, and perform ash frying operation. Use the slag hopper to slowly pour the drained aluminum ash into the rotary furnace, place a pot for receiving aluminum water under the furnace mouth, and open the dust collector. Use a slag rake to evenly distribute the fire on the surface of the ash in the furnace, so that the ash in the furnace can touch the fire and heat up rapidly (use the slag rake to stir u...

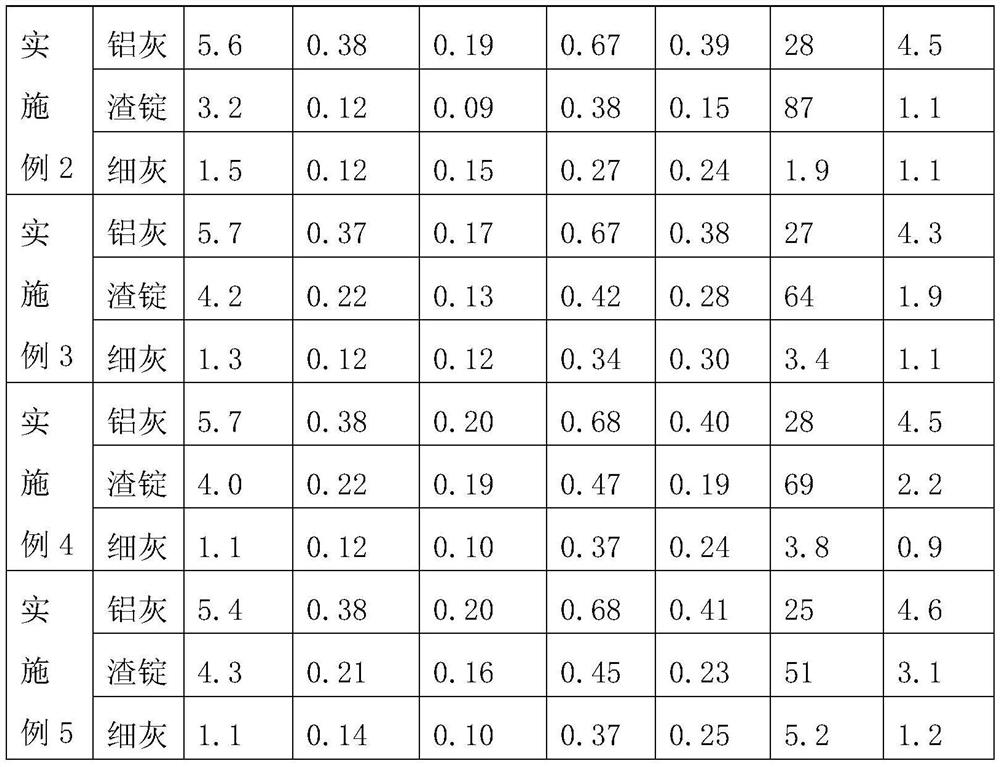

Embodiment 2

[0038] S1: Using crushed water hyacinth powder as carbon source and corn flour as nitrogen source, Streptococcus mutans ua159 was cultured, wherein the mass ratio of water hyacinth powder to corn flour was 1:1, and the culture temperature was 10°C.

[0039] S2: Pour aluminum ash into a culture tank containing a large amount of mutans streptococcus, and add sodium sulfate to it, the mass ratio of sodium sulfate to aluminum ash is 1:40, after stirring evenly, use mutans streptococcus to treat aluminum ash for 15 Hour.

[0040] S3: Take out the processed aluminum ash, drain it, and perform ash frying operation. Use the slag hopper to slowly pour the drained aluminum ash into the rotary furnace, place a pot for receiving aluminum water under the furnace mouth, and open the dust collector. Use a slag rake to evenly distribute the fire on the surface of the ash in the furnace, so that the ash in the furnace can touch the fire and heat up rapidly (use the slag rake to stir up, down,...

Embodiment 3

[0047] S1: Using crushed water hyacinth powder as carbon source and corn flour as nitrogen source, Streptococcus mutans ua159 was cultured, wherein the mass ratio of water hyacinth powder to corn flour was 1:1, and the culture temperature was 35°C.

[0048]S2: Soak the aluminum ash in sodium sulfate solution for 2 hours, the concentration of sodium sulfate in the sodium sulfate solution is 2mol / L. Pour the aluminum ash into a culture tank containing a large amount of mutans streptococcus, stir evenly, and use the mutans streptococcus to treat the aluminum ash for 15 hours.

[0049] S3: Take out the processed aluminum ash, drain it, and perform ash frying operation. Use the slag hopper to slowly pour the drained aluminum ash into the rotary furnace, place a pot for receiving aluminum water under the furnace mouth, and open the dust collector. Use a slag rake to evenly distribute the fire on the surface of the ash in the furnace, so that the ash in the furnace can touch the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com