Anodic oxidation method of titanium and titanium alloy in graphene/graphene oxide electrolyte

An anodic oxidation and graphene technology, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve problems such as poor conductivity, environmental protection, and low efficiency, and achieve improved biocompatibility and enhanced corrosion resistance and the effect of abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Step 1. Use a degreaser to clean the surface oil stains;

[0038] Step 2. Polish the metal titanium plate with 400#, 600#, 800#, 1200# water sandpaper in turn, and then polish it on the polishing cloth with silicon dioxide fine polishing liquid until there are no obvious scratches on the surface; Put in 3mol / L NaOH solution, alcohol, deionized water and ultrasonic cleaning at room temperature for 20min to remove the surface contamination layer, and finally dry it with a hair dryer for later use;

[0039] Step 3. In the 5mg / ml graphene oxide aqueous solution, add the reducing agent citric acid to make the concentration of citric acid reach 10mg / mL, heat the reduction reaction in an oil bath at 80°C for 8h, and obtain the graphene / graphene oxide electrolyte ;

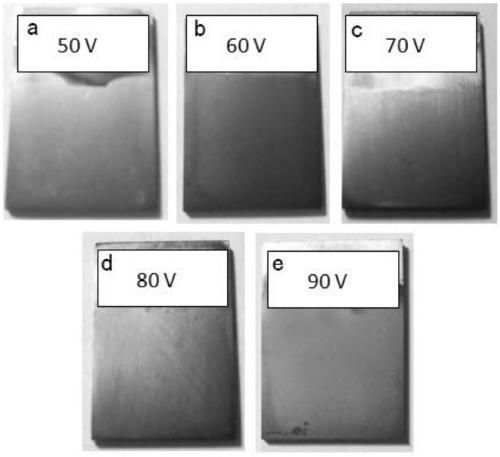

[0040] Step 4. Wrap the copper wire on the titanium alloy as the anode and immerse it in the electrolyte. The distance between it and the stainless steel cathode is 5cm. The DC power supply is oxidized at room tem...

Embodiment 2

[0042] Step 1. Use a degreaser to clean the surface oil stains;

[0043] Step 2. Polish the metal titanium plate with 400#, 600#, 800#, 1200# water sandpaper in turn, and then polish it on the polishing cloth with silicon dioxide fine polishing liquid until there are no obvious scratches on the surface; Put in 5mol / L NaOH solution, alcohol, deionized water and ultrasonic cleaning at room temperature for 20 minutes to remove the surface contamination layer, and finally dry it with a hair dryer for later use;

[0044] Step 3. In the 8mg / mL graphene oxide aqueous solution, add the reducing agent citric acid to make the citric acid concentration reach 10mg / mL, heat the reduction reaction in an oil bath at 95°C for 10h, and obtain the graphene / graphene oxide electrolyte ;

[0045] Step 4. Wrap the copper wire on the titanium alloy as the anode and immerse it in the electrolyte, with a distance of 8cm from the stainless steel cathode, and oxidize it with DC power at room temperatur...

Embodiment 3

[0047] Step 1. Use a degreaser to clean the surface oil stains;

[0048] Step 2. Polish the metal titanium plate with 400#, 600#, 800#, 1200# water sandpaper in turn, and then polish it on the polishing cloth with silicon dioxide fine polishing liquid until there are no obvious scratches on the surface; Put in 6mol / L NaOH solution, alcohol, deionized water and ultrasonic cleaning at room temperature for 20min to remove the surface contamination layer, and finally dry it with a hair dryer for later use;

[0049]Step 3. In the 10mg / mL graphene oxide aqueous solution, add the reducing agent citric acid to make the citric acid concentration reach 10mg / mL, heat the reduction reaction in an oil bath at 100°C for 12h, and obtain the graphene / graphene oxide electrolyte ;

[0050] Step 4. Wrap the copper wire on the titanium alloy as the anode and immerse it in the electrolyte, keep a distance of 10cm from the stainless steel cathode, and oxidize it with a DC power supply at room temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com