Electrochemical sensor and preparation method and application thereof

A sensor and electrochemical technology, applied in the field of electrochemical sensor and its preparation, can solve the problems of cumbersome operation steps, long analysis time, low sensitivity, etc., and achieve the effect of simple process, high sensitivity and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] In one embodiment, the preparation method comprises the following steps:

[0033] (1) pre-processing the electrode to obtain the treated electrode;

[0034] (2) applying the multi-walled carbon nanotube dispersion droplets to the treated electrode surface, and after the electrode surface is dried, the multi-walled carbon nanotube-modified electrode is obtained;

[0035] (3) drop-coating the polyoxometalate solution on the surface of the carbon nanotube-modified electrode, and after the electrode is dried, a multi-wall carbon nanotube-polyoxometalate modified electrode is obtained;

[0036] (4) Gold nanoparticles are electrodeposited on the surface of the multi-walled carbon nanotube-polyoxometalate modified electrode to obtain a working electrode modified by the multi-walled carbon nanotube-polyoxometalate-gold nanoparticle composite material.

[0037] The above preparation method is further explained below:

[0038] Preferably, the electrode is a glassy carbon electr...

Embodiment 1

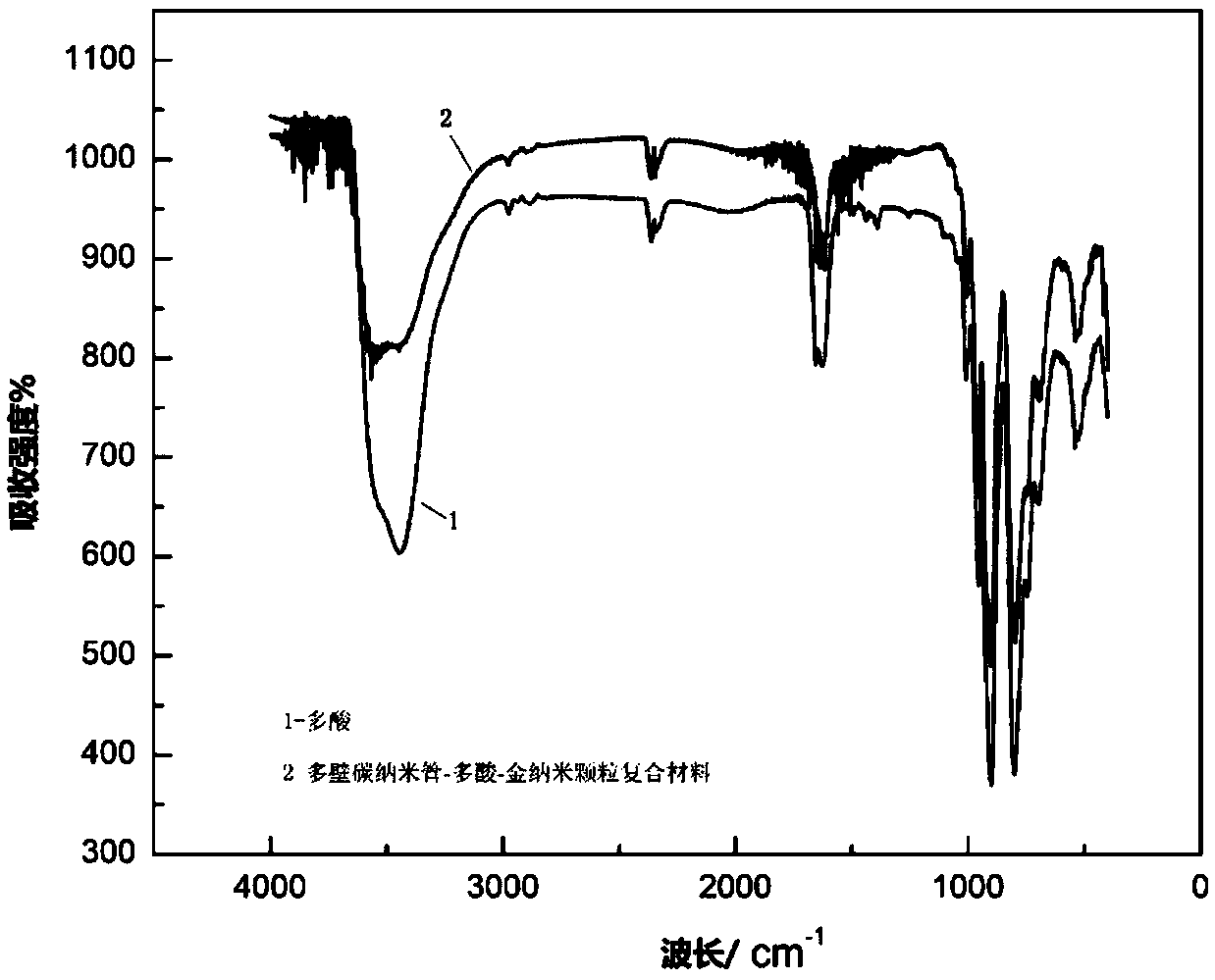

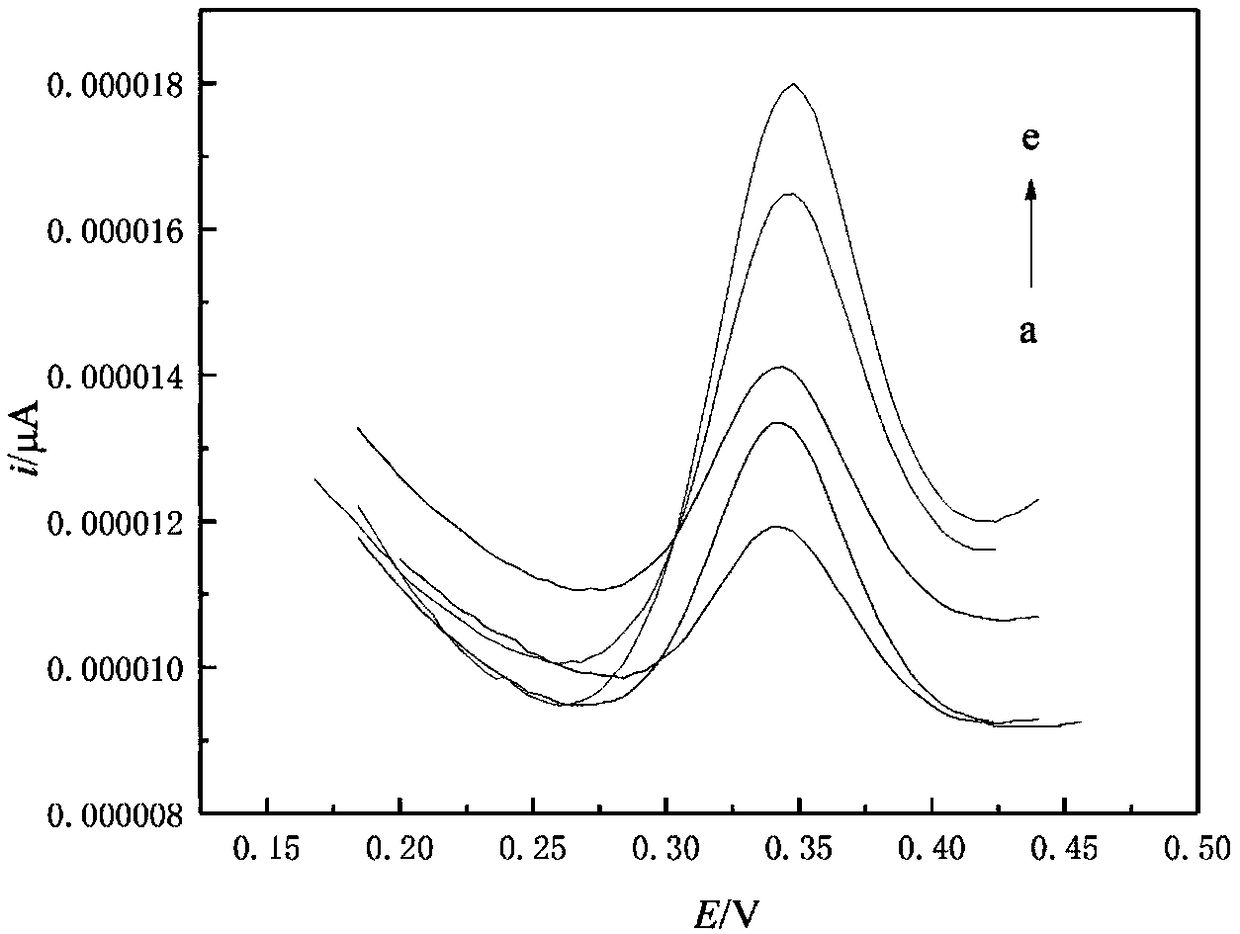

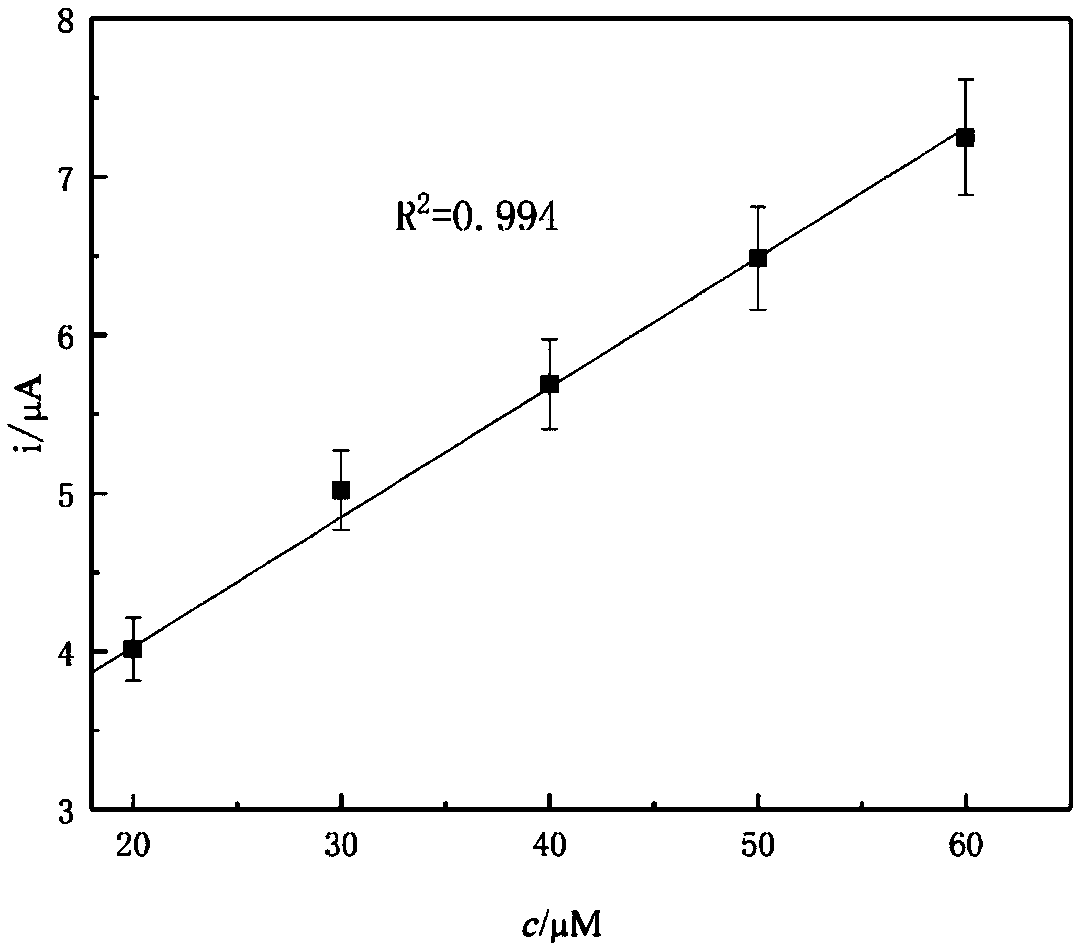

[0045] The electrochemical sensor of this embodiment includes an electrode and a multi-walled carbon nanotube-polyoxometalate-gold nanoparticle composite material coated on the surface of the electrode; the multi-walled carbon nanotube is acidified; the multi-metal Oxygenate is K 2 H 4 SiW 11 CuO 39 ·6H 2 O; the mass ratio of the multi-walled carbon nanotubes to the polyoxometalate is 1:15. The composite material is prepared by stacking multi-walled carbon nanotube layers, polyoxometalate layers and gold nanoparticle layers in sequence, and the number of cycles is one time.

[0046] The preparation method of the electrochemical sensor of the present embodiment comprises the following steps:

[0047] (1) Pre-treat the glassy carbon electrode with φ=3mm. For the first time, use aluminum oxide powder with a particle size of 1.0 μm for grinding treatment for 2 minutes, then ultrasonically clean it in deionized water for 3 minutes, and then wash it in absolute ethanol. Ultras...

Embodiment 2

[0052] The electrochemical sensor of this embodiment includes an electrode and a multi-walled carbon nanotube-polyoxometalate-gold nanoparticle composite material coated on the surface of the electrode; the multi-walled carbon nanotube is acidified; the multi-metal Oxygenate is K 2 H 4 SiW 11 CuO 39 ·6H 2 O; the mass ratio of the multi-walled carbon nanotubes to the polyoxometalate is 1:45.8. The composite material is prepared by stacking multi-walled carbon nanotube layers, polyoxometalate layers and gold nanoparticle layers in sequence, and the number of cycles is one time.

[0053] The preparation method of electrochemical sensor comprises the steps:

[0054] (1) Pre-treat the glassy carbon electrode with φ=3mm. For the first time, use aluminum oxide powder with a particle size of 1.0 μm for grinding treatment for 2 minutes, then ultrasonically clean it in deionized water for 3 minutes, and then wash it in absolute ethanol. Ultrasonic cleaning in medium for 2 minutes,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com