A kind of lithium ion battery negative plate and preparation method thereof

A technology for lithium ion batteries and negative electrode sheets, which is applied in battery electrodes, electrode manufacturing, electrode current collector coatings, etc., can solve the problems of large irreversible capacity of transition metal oxides, the cycle performance needs to be improved, and the coulombic efficiency is low. Suppression of capacity fluctuation, improvement of cycle stability, environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

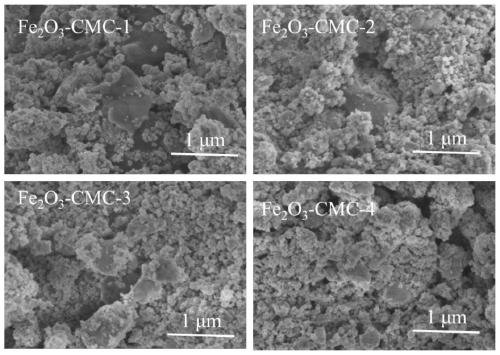

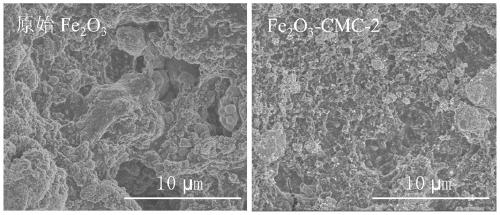

[0039] Commercial Micron Size Fe 2 o 3 with commercial NaBO 2 4H 2 According to four ratios of molar ratio 1:0.1~0.4, in argon or air atmosphere, weigh the corresponding mass of Fe 2 o3 and NaBO 2 4H 2 0 is packed into the ball mill tank (as shown in table 1), the ball-to-material ratio is 60:1, and the ball mill beads are made of stainless steel; the planetary ball mill is used to mix the two, the ball mill speed is 300 rpm, and the ball mill time is 2 hours. A negative electrode active material sample was prepared.

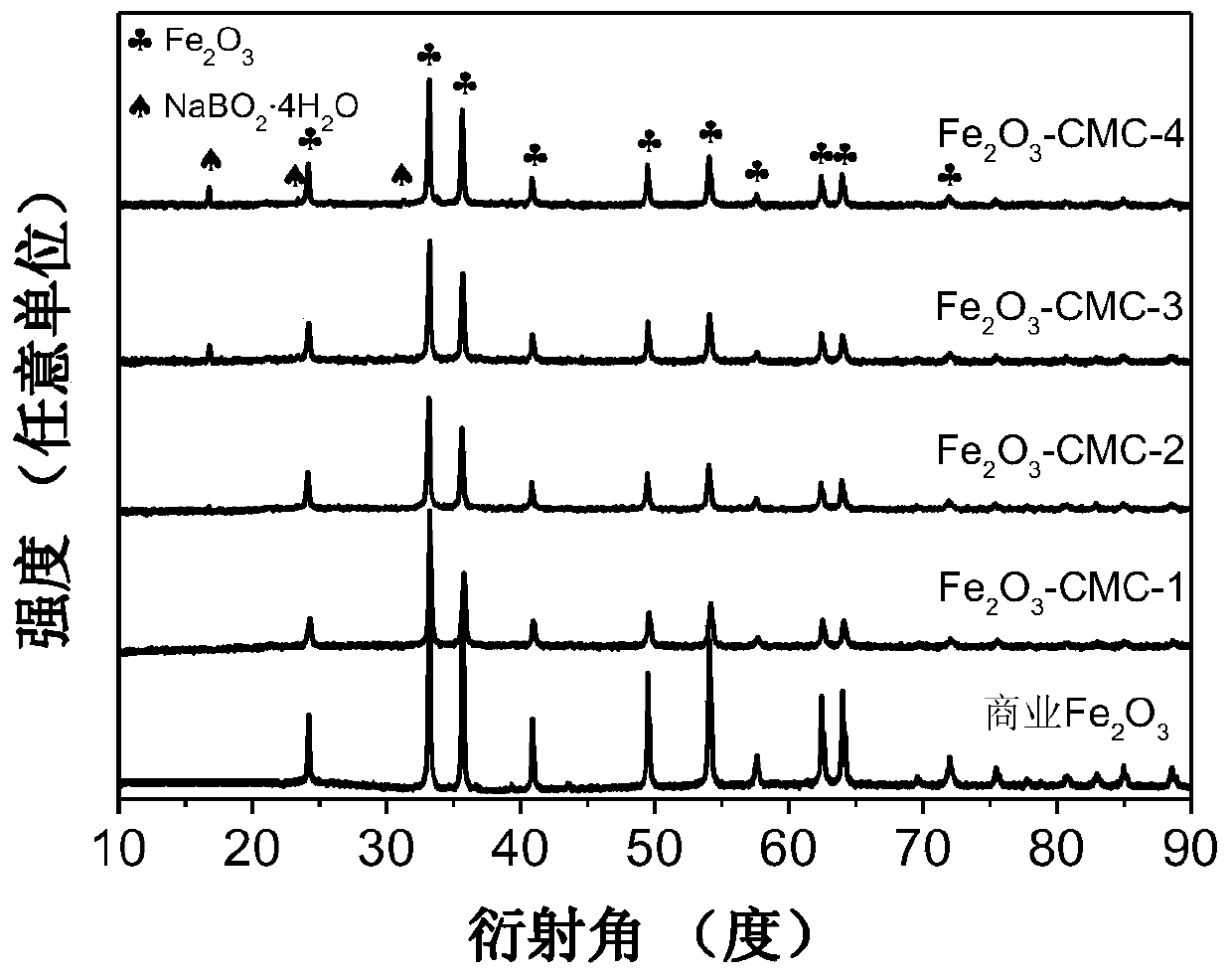

[0040] The X-ray diffraction spectrum (XRD) of the ball milling product is characterized by figure 1 As shown, it can be seen that the mixture after mixing is composed of Fe 2 o 3 and NaBO 2 4H 2 O composition, indicating that ball milling only achieves Fe 2 o 3 with NaBO 2 4H 2 A physical mixture of O and no chemical reaction between the two.

[0041] Take 0.45 grams of ball milling product and 0.129 grams of acetylene black, add 2000 milliliters...

Embodiment 2

[0051] Take 0.45 g of the ball milling product of Example 1 and 0.129 g of acetylene black, mix and add 2000 ml of SA solution with a mass fraction of 1% wt, and coat and prepare pole pieces marked as Fe 2 o 3 -SA-1, Fe 2 o 3 -SA-2, Fe 2 o 3 -SA-3, Fe 2 o 3 -SA-4.

[0052] Figure 5 for commercial Fe 2 o 3 , Fe 2 o 3 -SA-1, Fe 2 o 3 -SA-2, Fe 2 o 3 -SA-3, Fe 2 o 3 -Charge cycle performance curve of SA-4. Visible, four different proportions containing NaBO 2 Fe for binder additives 2 o 3 Compared with the original Fe of the control group, the negative electrode material 2 o 3 The specific capacity and cycle stability of the pole piece have been greatly improved.

[0053] Control group: take Fe 2 o 3 Mix 0.45 g with 0.129 g of acetylene black, add 2000 ml of SA solution with a mass fraction of 1% wt, and coat to prepare pole pieces.

[0054] where Fe 2 o 3 -SA-2 has a specific discharge capacity of 1169.5 mAh per gram for the first time, a specific c...

Embodiment 3

[0057] Take 0.45 g of the ball milling product of Example 1 and 0.129 g of acetylene black, add 1000 ml of SA solution with a mass fraction of 1%wt and 1000 ml of CMC solution with a mass fraction of 1%wt, and coat and prepare pole pieces marked as Fe 2 o 3 -SC-1, Fe 2 o 3 -SC-2.

[0058] Control group: take Fe 2 o 3 Mix 0.45 g with 0.129 g of acetylene black, add 1000 ml of SA solution with a mass fraction of 1%wt and 1000 ml of CMC solution with a mass fraction of 1%wt, and coat to prepare pole pieces.

[0059] Figure 6 for commercial Fe 2 o 3 , Fe 2 o 3 -SC-1, Fe 2 o 3 -Charge cycle performance curve of SC-2. Visible, four different proportions containing NaBO 2 Fe for binder additives 2 o 3 Compared with the original Fe of the control group, the negative electrode material 2 o 3 The specific capacity and cycle stability have been greatly improved.

[0060] where Fe 2 o 3 -SC-2's first discharge specific capacity is 1256.9 mAh / g, charge specific capaci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com