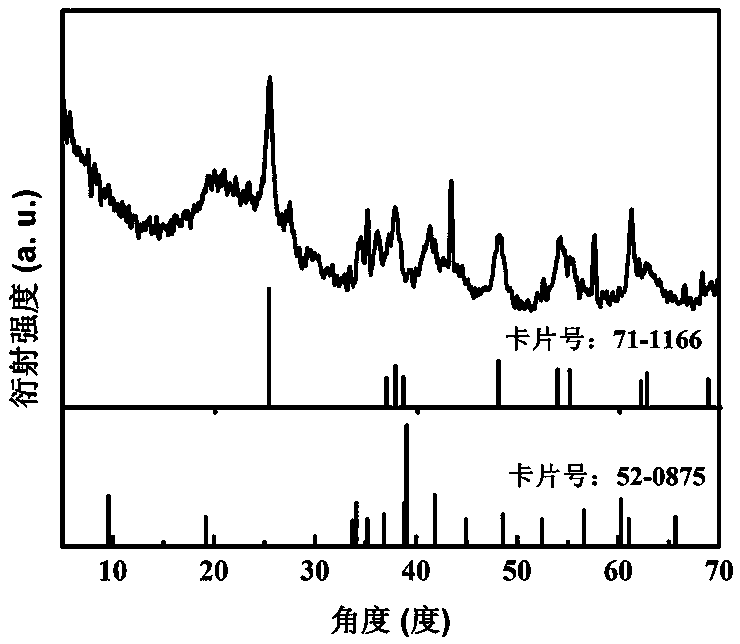

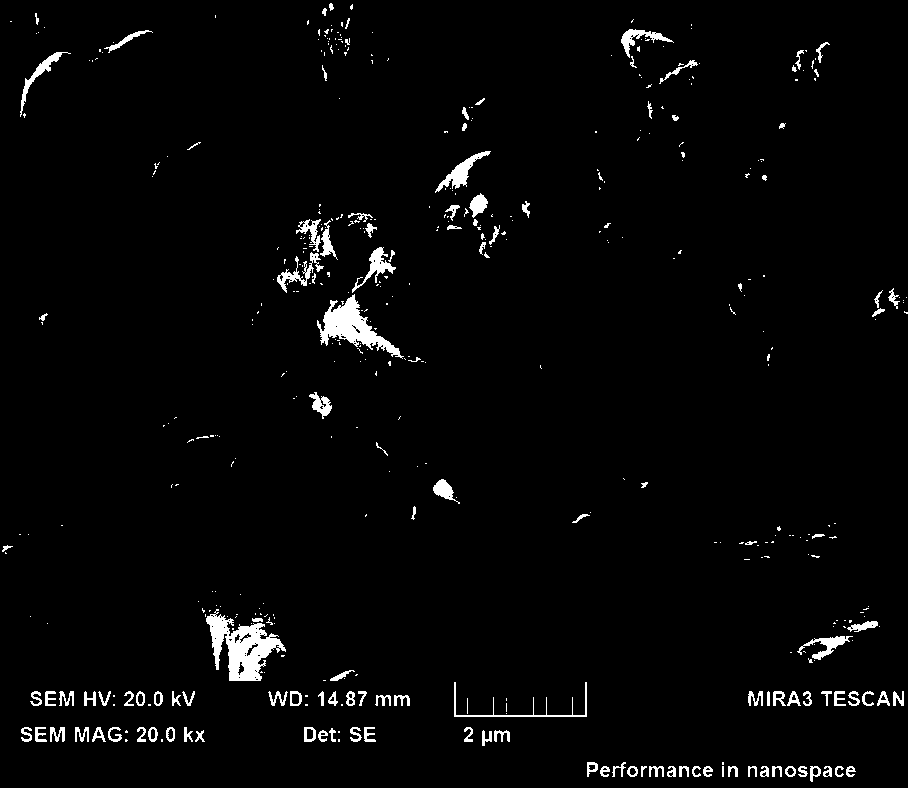

TiO2/graphene multi-element modified Mxene composite material and preparation method thereof

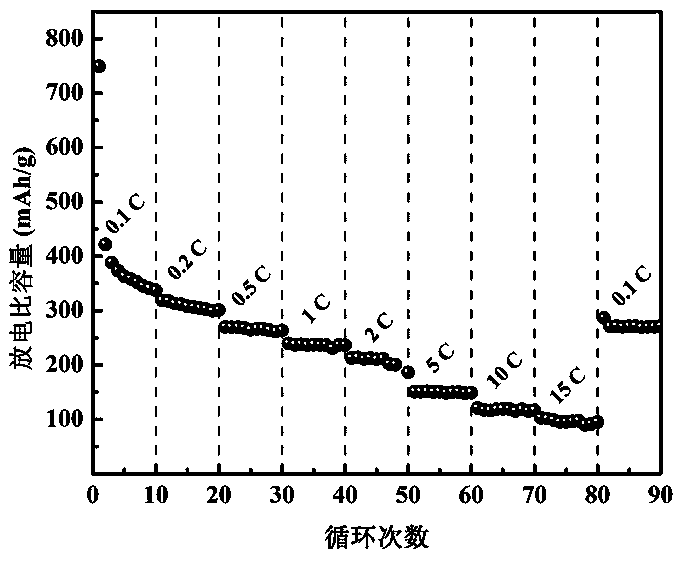

A technology of titanium dioxide and composite materials, applied in the field of composite materials and their preparation, can solve the problems of the longitudinal conductivity of Mxene materials embedded in other materials, the small interlayer spacing of Mxene materials, and the lack of modification and improvement of the longitudinal conductivity of Mxene materials, and achieve excellent performance. Cycling performance and capacity reversibility, effects of improving longitudinal and surface conductivity, and improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Add 30 g of HF acid (40% mass fraction) into a polytetrafluoroethylene tank, add 1.0 g of Mxene precursor to it, and stir for 6 h at 400 rpm at a constant temperature of 90 °C to carry out the Mxene precursor etching;

[0037] (2) Add the Mxene obtained in step (1) into water, centrifuge at 10,000 rpm, cross-wash the precipitate with deionized water and absolute ethanol for 10 times, ultrasonicate at 400 W for 1 h, and incubate at 80°C , dried for 10 h to obtain Mxene material;

[0038] (3) Add 0.1 g of the Mxene material obtained in step (2) into 60 mL of deionized water, conduct ultrasonic dispersion at 400 W for 1 h, add 0.8 g of ammonium bicarbonate, and stir at 400 rpm for 2 h to obtain a surface Charge modified Mxene material dispersion;

[0039] (4) Add 0.005 g of nanoscale titanium dioxide and graphene oxide into 5 mL of deionized water, and disperse ultrasonically for 2 h at 400 W to obtain titanium dioxide dispersion and graphene oxide dispersion, respec...

Embodiment 2

[0050] (1) Add 30 g of HF acid (mass fraction 25%) into a polytetrafluoroethylene tank, add 1.0 g of Mxene precursor to it, and stir for 10 h at 300 rpm at a constant temperature of 85 °C to carry out the Mxene precursor etching;

[0051] (2) Add the Mxene obtained in step (1) into water, centrifuge at 5000 rpm, cross-wash the precipitate with deionized water and absolute ethanol for 10 times, ultrasonicate at 400 W for 1 h, and store at 80 °C , dried for 10 h to obtain Mxene material;

[0052] (3) Add 0.1 g of the Mxene material obtained in step (2) into 60 mL of deionized water, perform ultrasonic dispersion at 400 W for 1 h, add 1.5 g of ammonia water, and stir at 400 rpm for 1 h to obtain the surface charge modification. Proactive Mxene material dispersion;

[0053] (4) Add 0.01 g of nanoscale titanium dioxide and graphene oxide into 5 mL of deionized water, and disperse ultrasonically for 2 h at 400 W to obtain titanium dioxide dispersion and graphene oxide dispersion, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Internal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com