Corn straw silage feed preparing technology

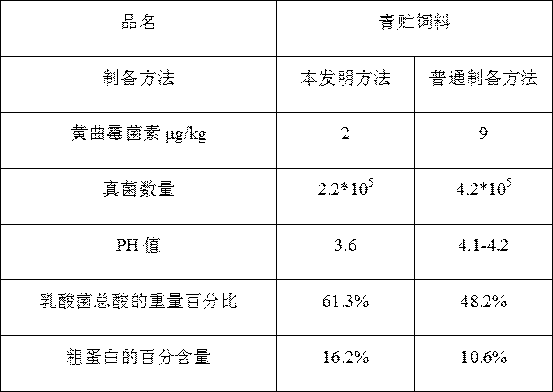

A corn stalk and silage technology, applied in the field of silage, can solve the problems of slow drop of silage PH, large nutrient loss of silage, long activity time of spoilage bacteria, etc. Possible effects of causing mildew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: A kind of corn stalk silage production process

[0034] (1) Preparation of silage pond: feed 150 cows, and according to the daily feeding amount of 8kg per cow, 1200kg of silage should be prepared, according to the silage density of 270kg / m 3 , determine the length of the silo, and at the same time determine the volume of the silo, that is, the construction of 1200m 3 The silo tank has a capacity of 324 tons; the inner wall of the silo tank must have a slope-shaped entrance surface with a slope angle of 30°. The side of the silo tank is a brick-concrete surface, and the bottom surface is a concrete surface. When the wall collapses, the four corners of the silage pond must be made into arcs to facilitate the sinking of the silage material and discharge residual gas. One end of the silage pond wall is open to allow the water in the silage process to flow out and be used for feeding. It should be used before silage Dig the pond in about 1 week and let the su...

Embodiment 2

[0042] Embodiment 2: A kind of corn stalk silage production process

[0043] (1) Preparation of the silage pond: 200 cows are raised, and 1400kg of silage needs to be prepared according to the daily feeding amount of 7kg per cow, and the silage density is 270kg / m 3 , determine the length of the silo, and at the same time determine the volume of the silo, that is, the construction of 1400m 3 The silage pool has a capacity of 372 tons; the inner wall of the silo pool must have a slope-shaped entrance surface with a slope angle of 20°. When the wall collapses, the four corners of the silage pond must be made into arcs to facilitate the sinking of the silage material and discharge residual gas. One end of the silage pond wall is open to allow the water in the silage process to flow out and be used for feeding. It should be used before silage Dig the pond in about 1 week and let the sun irradiate the bacteria. The location of the silage pond should be 0.5 meters above the groundwa...

Embodiment 3

[0051] Embodiment 3: A kind of corn stalk silage production process

[0052] (1) Preparation of the silage pond: 250 cows are raised, and 1500kg of silage is required according to the daily feeding amount of 6kg per cow, and the silage density is 270kg / m 3 , determine the length of the silo, and at the same time determine the volume of the silo, that is, the construction of 1530m 3 The silage tank has a capacity of 413 tons; the inner wall of the silo tank must have a slope-shaped entrance surface with a slope angle of 40°. The side of the silo tank is a brick-concrete surface, and the bottom surface is a concrete surface. When the wall collapses, the four corners of the silage pond must be made into arcs to facilitate the sinking of the silage material and discharge residual gas. One end of the silage pond wall is open to allow the water in the silage process to flow out and be used for feeding. It should be used before silage Dig the pond in about 1 week and let the sun irr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com