Method for preparing high-concentration ester flavoring wine from chi-flavour Baijiu byproducts

A seasoning wine and by-product technology, which is applied in the field of wine making, can solve the problems of high technical requirements, high equipment cost, and difficulty in popularization, and achieve the effects of simple process flow, low equipment investment, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

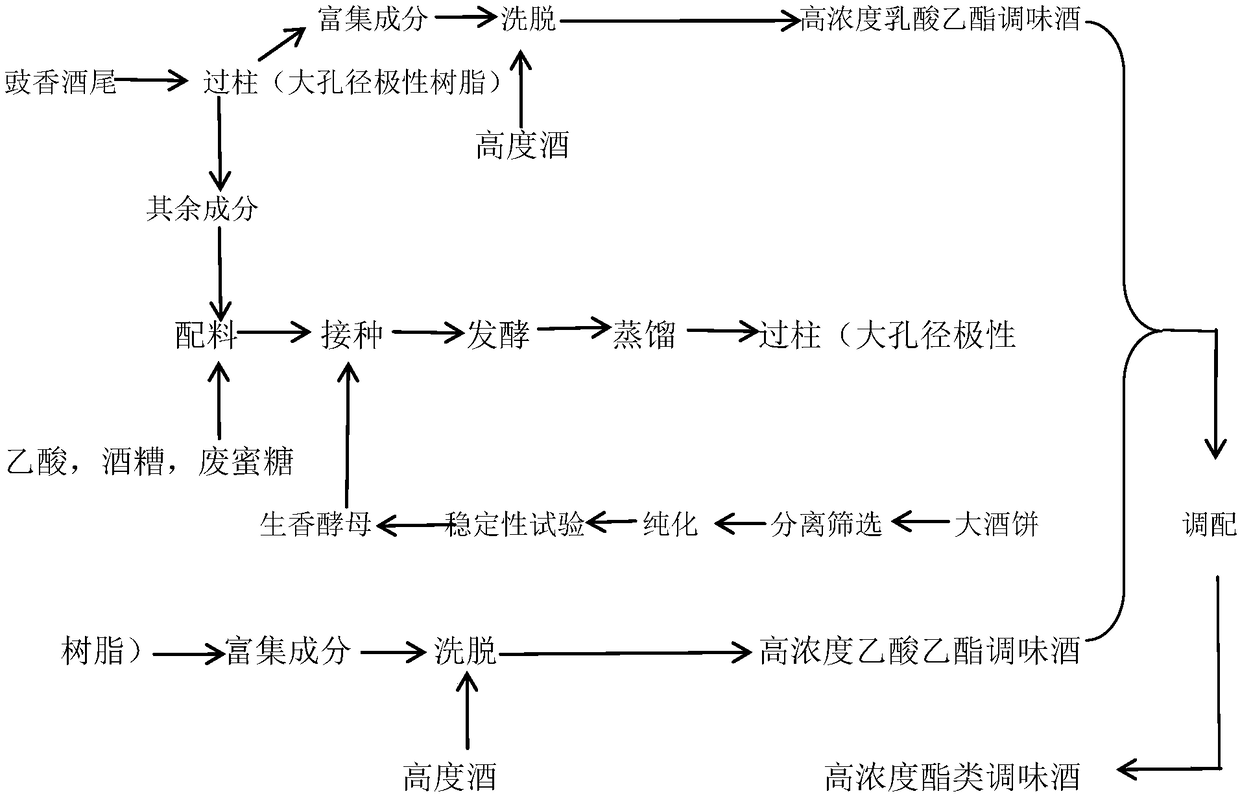

[0023] refer to figure 1 , a method for preparing high-concentration ester flavored wine by using the by-product of soya-flavored liquor according to the present invention, comprising the following steps:

[0024] Step S1: Adsorption and enrichment of ethyl lactate through a macroporous polar resin column for soy-flavored wine tail, and then eluting with high-grade wine with an alcohol content of 95%vol to obtain ethyl lactate with a concentration of 1.5-2.0g / L Ester seasoning wine, the remaining liquid after passing through the column is used for later use;

[0025] Step S2: Obtain the aroma yeast through screening, separation and purification in the soy-flavored wine cake;

[0026] Step S3: Use the residual liquid and distiller's grains obtained in step S1 as fermentation substrates, the amount of distiller's grains added is 25% to 30% of the total mass, and the residual liquid is added to adjust the alcohol content of the liquid to 2%, and then use waste molasses to adjust...

Embodiment 2

[0037] Example 2: Compared with Example 1, the difference is that in step S3, the amount of distiller's grains added is 30%, and waste molasses is used to adjust the mash so that the sugar content is 15.5%.

Embodiment 3

[0038] Embodiment 3: Compared with Embodiment 1, the difference is that the addition of distiller's grains is 28%, and the mash is adjusted with waste molasses so that the sugar content is 14%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com