Method for preparing titanium oxide micro-nano array supported monoatomic platinum catalyst

A nano-array, platinum catalyst technology, applied in the field of materials, can solve the problem of reducing the catalytic activity of the platinum utilization rate catalyst, and achieve the effects of suppressing local unevenness, uniform heating, and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

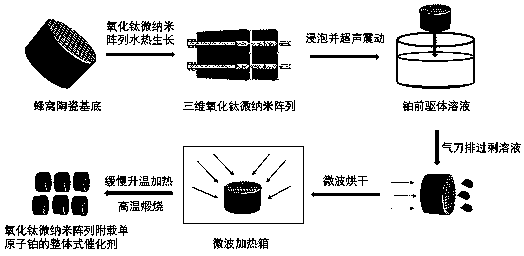

[0025] The first step: hydrothermal growth of rutile-titanium oxide nanoarrays on a honeycomb ceramic substrate. After the cordierite honeycomb substrate is loaded with titanium oxide seed crystals, it is immersed in the titanium oxide growth solution as a whole, and sealed in a high-pressure reactor for high-temperature hydrothermal growth. The titanium oxide growth solution is generally prepared by mixing the organic precursor of titanium oxide, hydrochloric acid, and organic solvents (toluene, ethyl ketone, n-hexane).

[0026] The second step: the impregnation of the nano-array integrated honeycomb ceramics in the platinum active precursor. After hydrothermal growth, the honeycomb ceramics integrated with titanium oxide nanoarrays underwent a series of cleaning and drying, and then were immersed in a certain concentration of platinum active precursor aqueous solution, and the solution and the substrate were placed in an ultrasonic device for one minute to exclude the nanoar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com