Method for preparing TiAl/TC4 micro-laminate composite material by selective laser melting

A technology of laser selective melting and composite materials, which is applied in the direction of additive manufacturing, additive processing, and improvement of process efficiency. Temperature gradient, good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

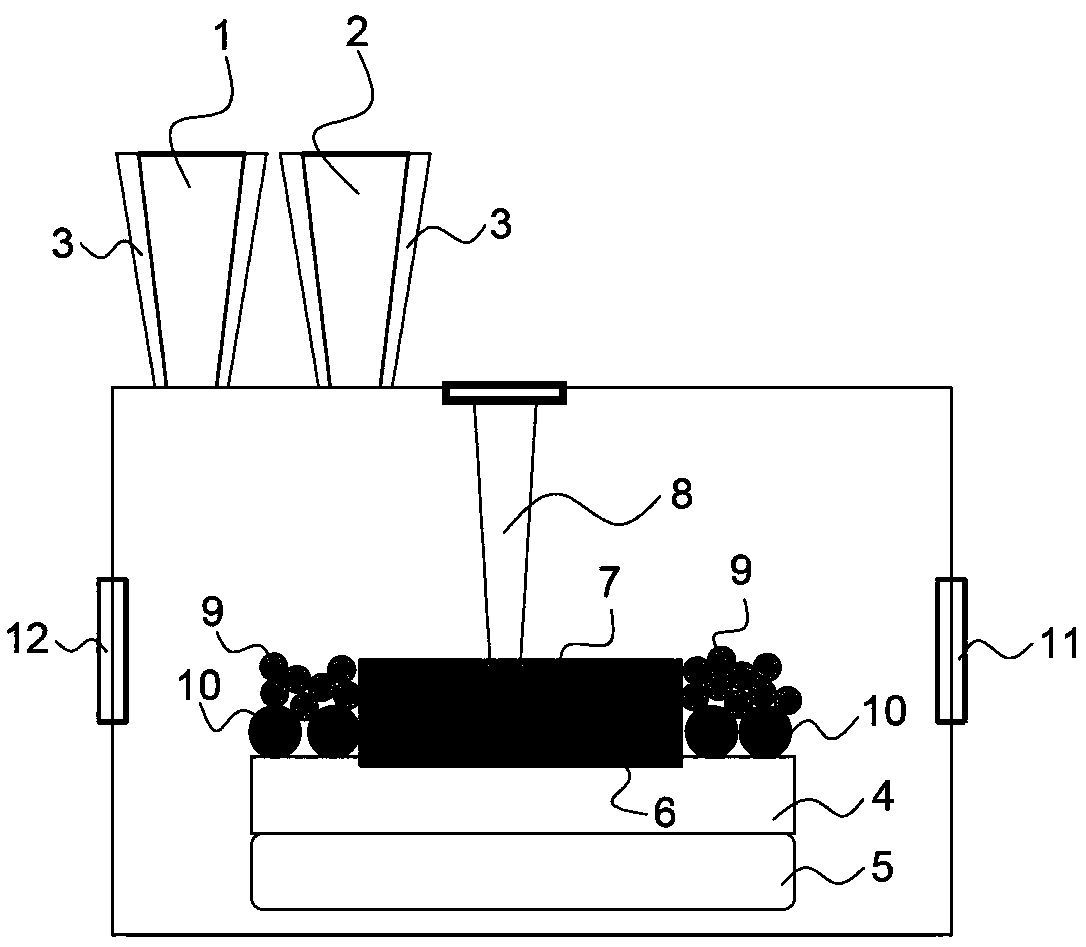

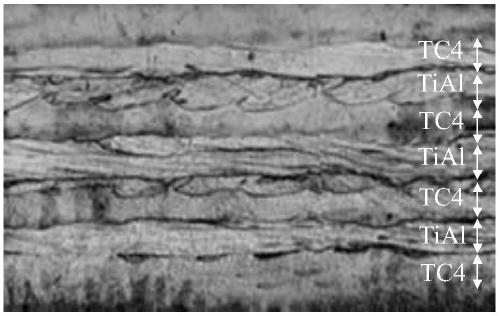

[0070] like figure 1 As shown, a method for preparing TiAl / TC4 micro-laminated composites by laser selective melting. The laser selective melting equipment is equipped with an IPG 400W fiber laser, and the spot diameter is 100 μm; the forming room is equipped with a preheating platform, and the maximum preheating temperature is 200 ℃; Equipped with two powder storage boxes, respectively storing TiAl powder and TC4 powder, the preheating device of the powder storage box is a heating platform customized by Shanghai Optical Instrument Factory, with a maximum temperature of 400 degrees. The powder adopts gas-atomized Ti-48Al-2Cr-2Nb (powder particle size is 15-48 μm), TC4 powder (powder particle size is 63-97 μm). The experimental substrate is a cold-rolled Ti plate, and the size of the substrate is 250*250*15mm. The gas drying filter is Baihui AC4010-04; the gas heater is Jingcheng Machinery QW-500, and the maximum heating temperature is 100°C. The day before the experiment, th...

Embodiment 2

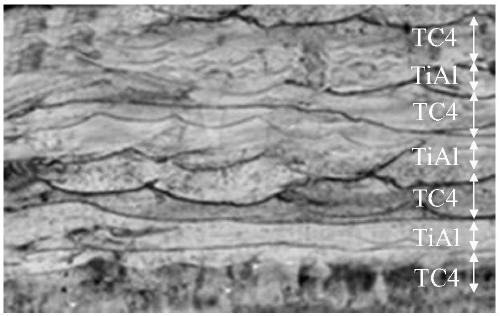

[0079] like figure 1 As shown, a method for preparing TiAl / TC4 micro-laminated composites by laser selective melting, embodiment 2 is basically the same as embodiment 1, the difference is the layer ratio of TC4 and TiAl in step 4, every 4 layers of TC4 Then lay 2 layers of TiAl alternately.

[0080] like image 3As shown, the TiAl / TC4 micro-laminate block formed part obtained in Example 2 has regular shape, compactness and no cracks. Observation of the metallographic structure of the cross-section shows that there are no pores and cracks in the formed part structure. Due to the increased content of TC4, the mechanical properties are better than those of the formed part in Example 1. The measured tensile strength and elongation in the parallel forming direction are 530 MPa and 2.32%, respectively. The tensile strength and elongation measured at 700°C were 460MPa and 15.45%, respectively.

[0081] The conventional technologies in the above embodiments are known to those skil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elongation | aaaaa | aaaaa |

| Elongation | aaaaa | aaaaa |

| Elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com