Macroscopic preparation method for high yield carbon quantum dot

A carbon quantum dot, high-yield technology, applied in the field of high-yield carbon quantum dot preparation, can solve the problems of complex raw material pretreatment process, low carbon quantum dot yield, cumbersome process steps, etc., and achieve convenient large-scale production , high yield and quantum yield, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

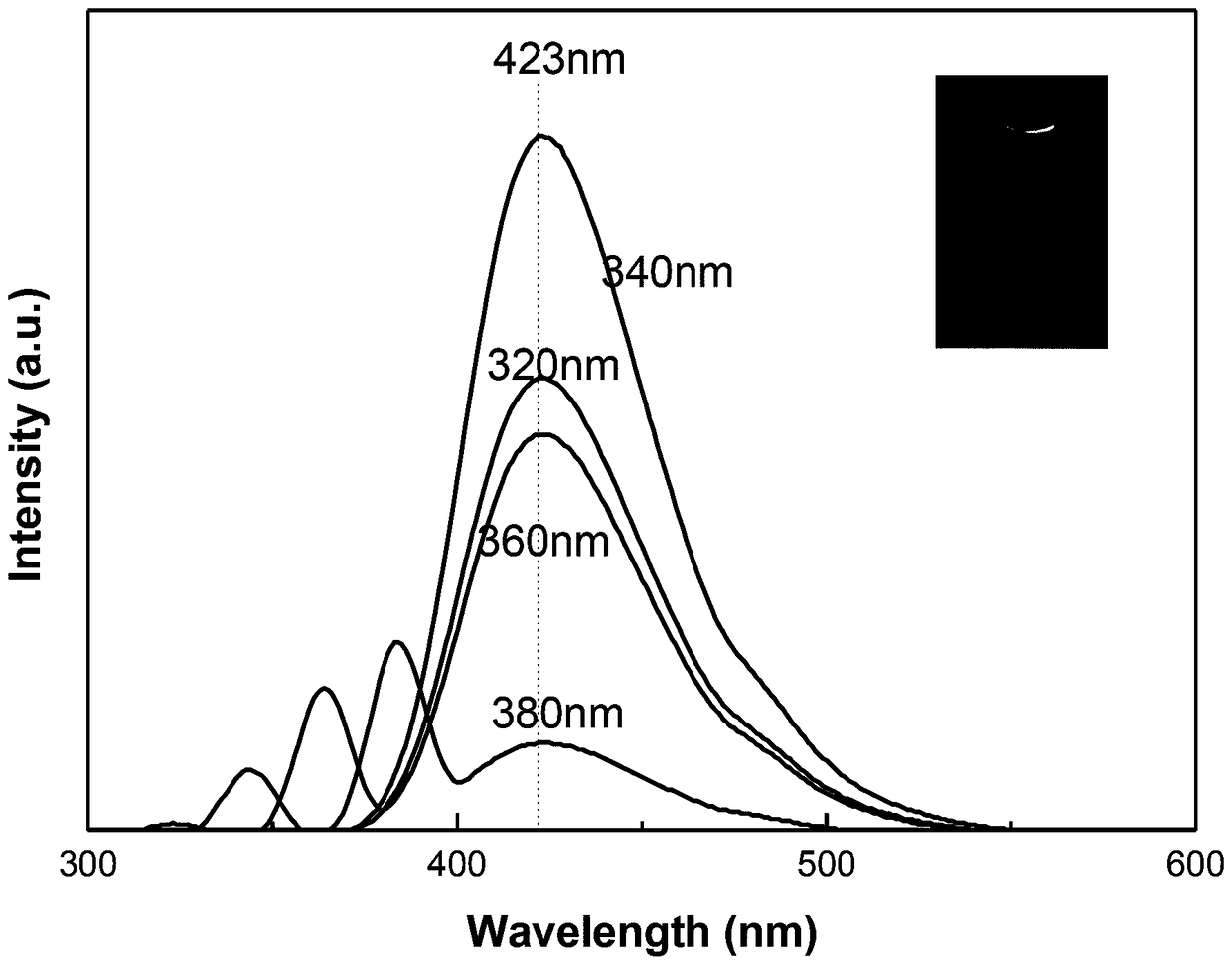

Embodiment 1

[0009] Dissolve 10 grams of 2-aminoterephthalic acid in 1000 milliliters of water at room temperature, then transfer to an autoclave and heat to 180 o C, keep warm for 12 hours; after cooling to room temperature, dialyze the reaction solution with a dialysis bag with a molecular weight cut-off of 500D for 48 hours, and change the water every 12 hours; o C was freeze-dried to powder to obtain carbon quantum dots, which emitted bright blue fluorescence under 365nm ultraviolet light irradiation.

Embodiment 2

[0011] Dissolve 4 grams of 2-aminoterephthalic acid and 0.58 grams of ethylenediamine in 400 milliliters of water at room temperature, then transfer to an autoclave and heat to 180 o C, keep warm for 18 hours; after cooling to room temperature, dialyze the reaction solution with a dialysis bag with a molecular weight cut-off of 500D for 48 hours, and change the water every 12 hours; o C was lyophilized to powder to obtain carbon quantum dots, which emitted strong blue fluorescence under 365nm ultraviolet light irradiation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com