Preparation method of molybdenum disulfide-cobalt sulfide-carbon ternary composite in-situ electrode

A molybdenum disulfide, in-situ electrode technology, applied in the direction of electrodes, battery electrodes, electrode shapes/types, etc., can solve the problems of expensive noble metal materials, lack of long-term operation stability, fuel oxidation molecular immunity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

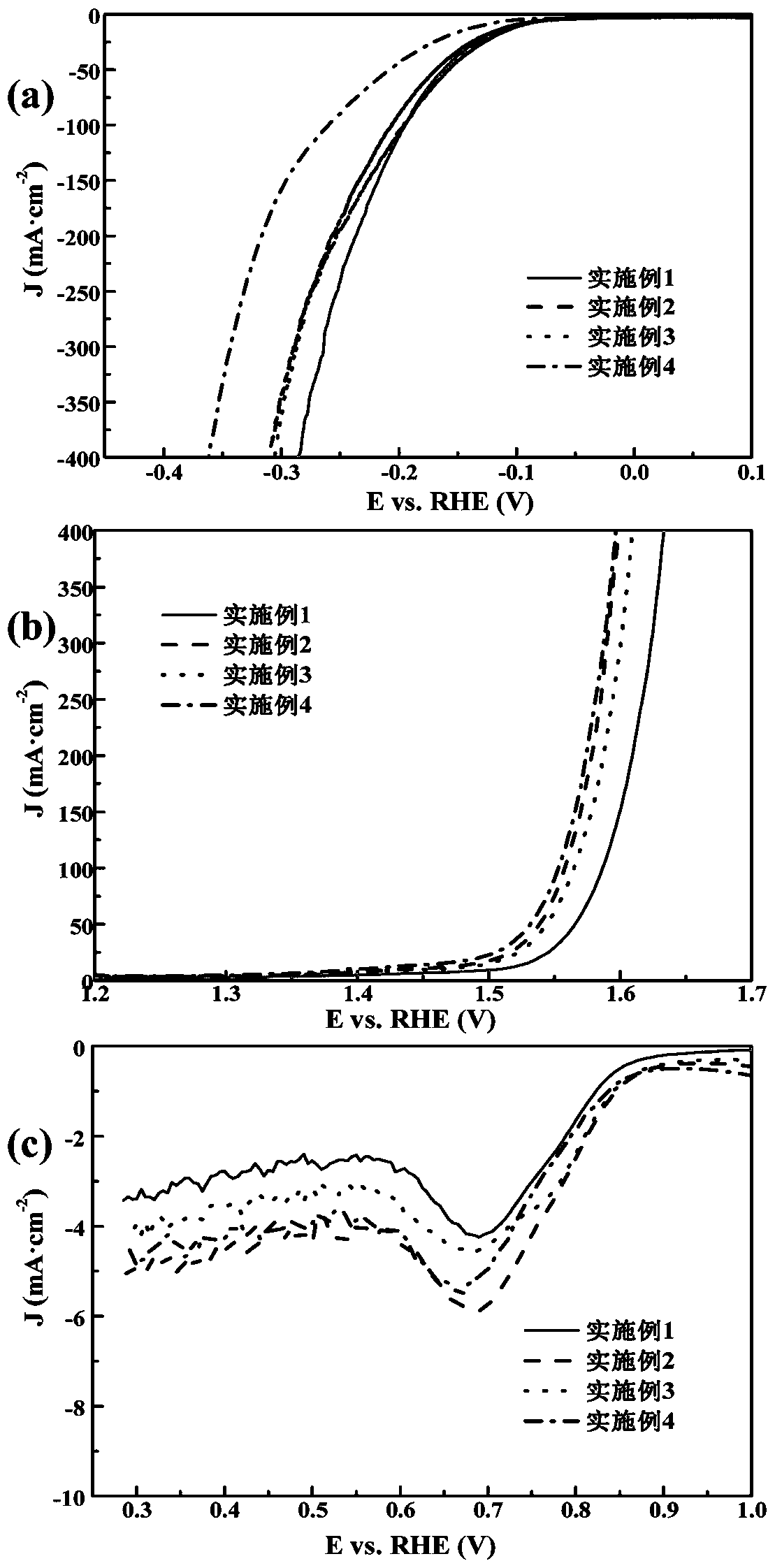

Embodiment 1

[0019] Dissolve molybdenum pentachloride, cobalt chloride hexahydrate, Tx-100 and thiourea in 2.7 mL N,N-dimethylformamide solution at room temperature, the total amount of molybdenum pentachloride and cobalt chloride hexahydrate The concentration is 400mM, the concentration ratio of the two substances is 1:1, the amount of Tx-100 is 0.3mL, and the concentration of thiourea is 1000mM. Soak the carbon paper in the precursor solution for 30 minutes, take it out, dry it on a hot table at 80°C for 10 minutes, then apply the precursor solution evenly on the carbon paper, and then continue to dry for 30 minutes. Put the coated carbon paper into a tube furnace, react at 600 °C for 1 h under Ar atmosphere, and take it out after natural cooling.

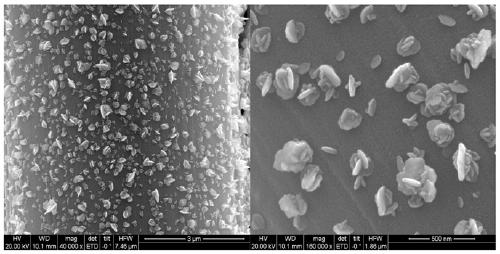

Embodiment 2

[0021] Dissolve molybdenum pentachloride, cobalt chloride hexahydrate, Tx-100 and thiourea in 2.7 mL N,N-dimethylformamide solution at room temperature, the total amount of molybdenum pentachloride and cobalt chloride hexahydrate The concentration is 400mM, the concentration ratio of the two substances is 1:3, the amount of Tx-100 is 0.3mL, and the concentration of thiourea is 1000mM. Soak the carbon paper in the precursor solution for 30 minutes, take it out, dry it on a hot table at 80°C for 10 minutes, then apply the precursor solution evenly on the carbon paper, and then continue to dry for 30 minutes. The coated carbon paper was placed in a tube furnace, reacted at 600 °C for 1 h under Ar flow, and was taken out after naturally cooling to room temperature.

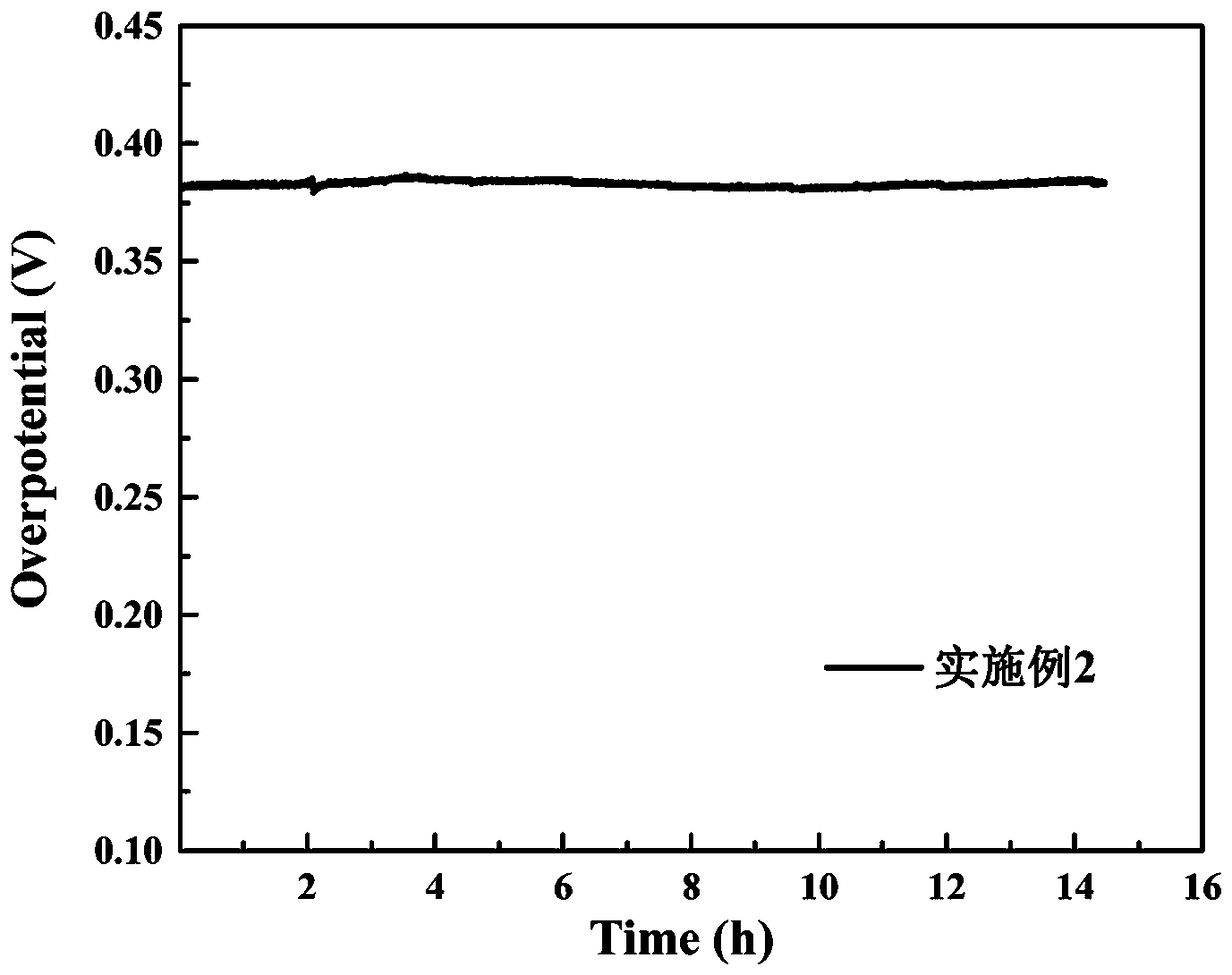

[0022] figure 1 For the prepared molybdenum disulfide-cobalt sulfide-carbon in situ electrode of embodiment 2 at 50mA / cm 2 Stability test graph performed under constant current. As can be seen from the figure, the ...

Embodiment 3

[0024] Dissolve molybdenum pentachloride, cobalt chloride hexahydrate, Tx-100 and thiourea in 2.7 mL N,N-dimethylformamide solution at room temperature, the total amount of molybdenum pentachloride and cobalt chloride hexahydrate The concentration is 400mM, the concentration ratio of the two substances is 1:3, the amount of Tx-100 is 0.3mL, and the concentration of thiourea is 1000mM. Soak the carbon paper in the precursor solution for 30 minutes, take it out, dry it on a hot table at 80°C for 10 minutes, then apply the precursor solution evenly on the carbon paper, and then continue to dry for 30 minutes. The coated carbon paper was placed in a tube furnace, reacted at 600 °C for 1 h under Ar flow, and was taken out after naturally cooling to room temperature. Continue to react the carbon paper taken out at 400°C in the air for 30 minutes, and then take it out after naturally cooling to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Limiting current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com