A kind of barley hydrolyzate, its preparation method and its application in cosmetics

A technology of hydrolyzate and cosmetics, applied in the field of barley hydrolyzate, its preparation, can solve the problems of improved antiseptic performance of barley extract, lower consumer acceptance, and higher proportion, so as to reduce antiseptic performance, easy control, and reduce stickiness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

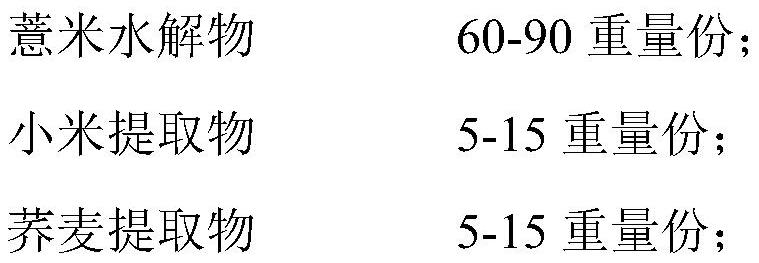

Image

Examples

Embodiment 1~7

[0028] A preparation method of barley hydrolyzate, comprising the steps of:

[0029] In step (1), the seed of Job's tears is pulverized, and the mesh particle size after pulverization is A mesh;

[0030] In step (2), add purified water (ratio of solid to liquid is H), add B enzyme to hydrolyze at a temperature of C degrees Celsius, and the hydrolysis time is D hours;

[0031] Step (3), centrifugal separation, taking the liquid part;

[0032] Step (4), high temperature goes out enzyme, makes enzyme inactivation precipitation, and temperature is about E degree Celsius, and the time is about F minute;

[0033] In step (5), membrane filtration is used to obtain permeate and retentate, and the retentate is dried to obtain barley hydrolyzate, wherein the pore size of membrane filtration is about G μm.

[0034] See Table 1 for the values of the above parameters.

[0035] Table 1

[0036]

[0037]

Embodiment 8

[0038] Embodiment 8: to tyrosinase activity inhibition experiment

[0039] Reagents: tyrosinase, tyrosine, sodium dihydrogen phosphate, disodium hydrogen phosphate, positive control (arbutin, nicotinamide), sample, deionized water.

[0040] Specific operation: as shown in Table 2, sequentially add phosphate buffer solution, sample solution, and tyrosine solution into the test tube, and place in a water bath at 35° C. for 10 minutes. Then, add tyrosinase solution, mix well, and incubate at 35°C for 30 minutes, transfer to a cuvette quickly, and measure the absorbance at 475nm.

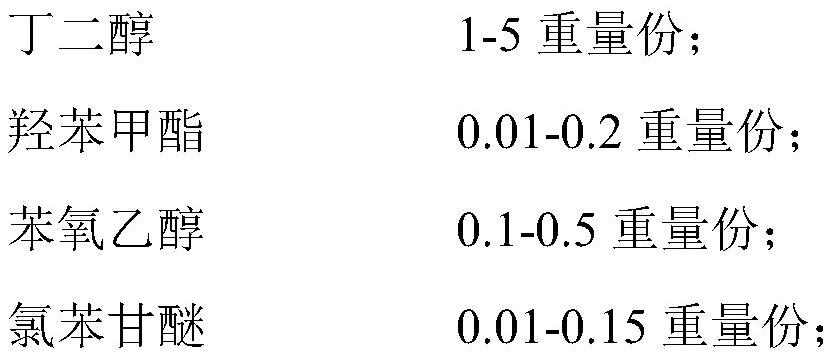

[0041] Table 2

[0042]

[0043] The absorbance value of the test group is A1, the absorbance value of the negative control group is A2, the absorbance value of the positive control group is A3, and the inhibition rate=1-[(A1-A2) / (A3-A2)]*100%.

[0044] Please see Table 3 for the results of the tyrosine inhibition test.

[0045] table 3

[0046]

[0047] In Table 3, sample 1 is the barley hy...

Embodiment 9

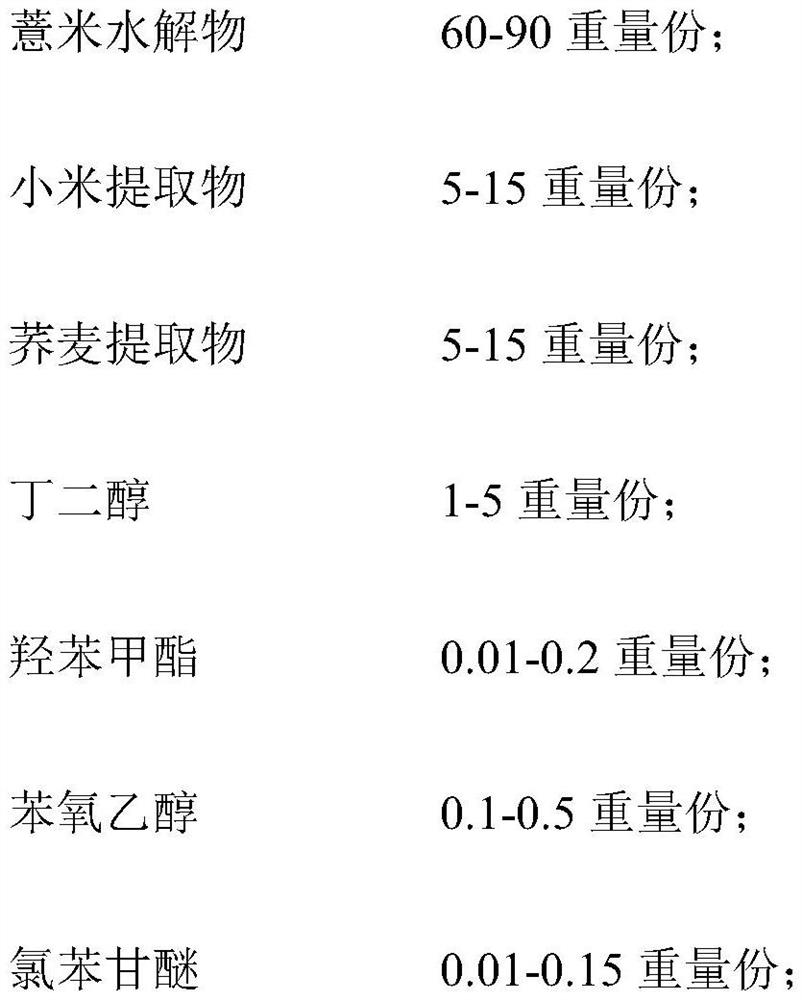

[0049] Embodiment 9: Performance test of barley hydrolyzate

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com