A method for characterizing the pore size of microporous membranes

A microporous membrane and characterization technology, applied in the field of water treatment, can solve the problems of high measured pressure, sample deformation results, insufficient safety and environmental protection, etc., and achieve the effects of being conducive to popularization, good repeatability, and simple and fast experimental process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

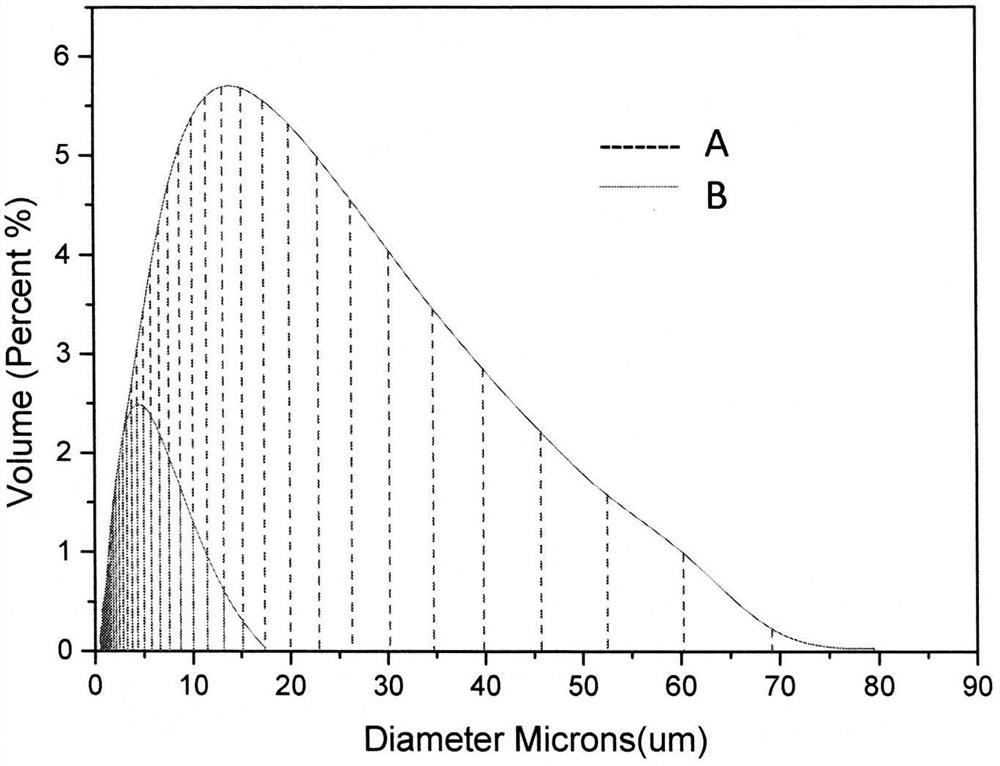

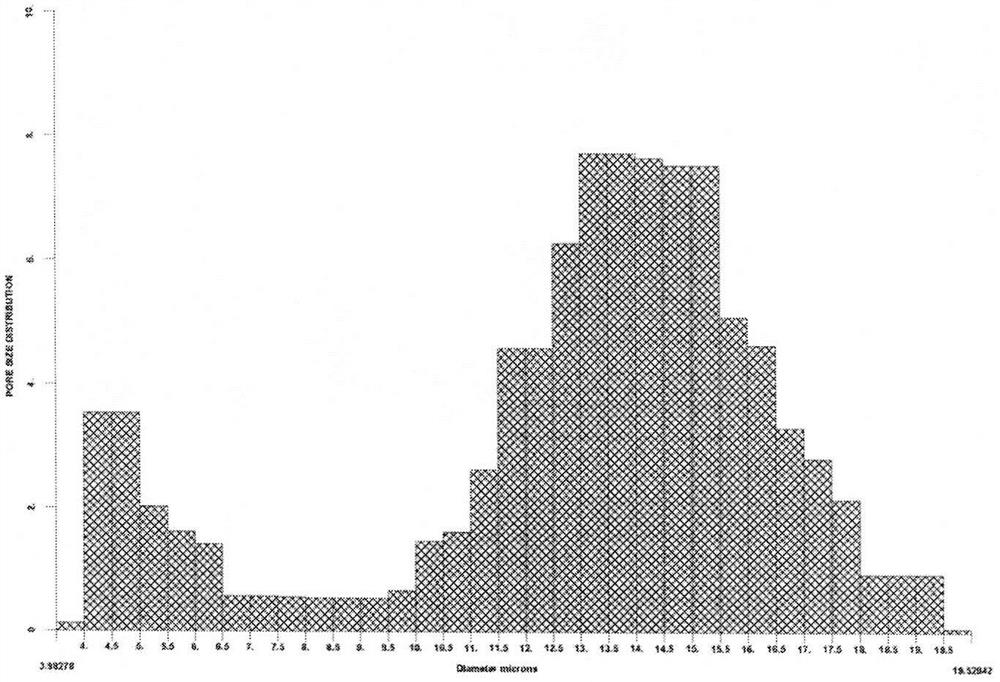

[0033] First weigh the SiO with various d50 indicators 2 Microspheres and masses: 10μm 0.01g, 15μm 0.04g, 20μm 0.2g, 25μm 0.6g, 30μm 0.8g, 35μm 0.6g, 40μm 0.2g, 45μm 0.04g and 50μm 0.01g. Then the above SiO 2 The microsphere powder is subjected to anti-silicic acid colloidal treatment and heat treatment, and the above-mentioned various SiO 2 Loaded in different crucibles, placed in a muffle furnace, raised from room temperature to 500°C in 60 minutes, raised to 600°C in 30 minutes, maintained at 600°C for 2 hours, and finally cooled naturally. After calcination, the above SiO 2 The powder is ground separately. Then the suspension was configured, and the ground various SiO 2 The powder was added to 247.5ml of water, stirred and mixed, and configured into a 10wt% suspension to simulate raw water for testing microporous membranes.

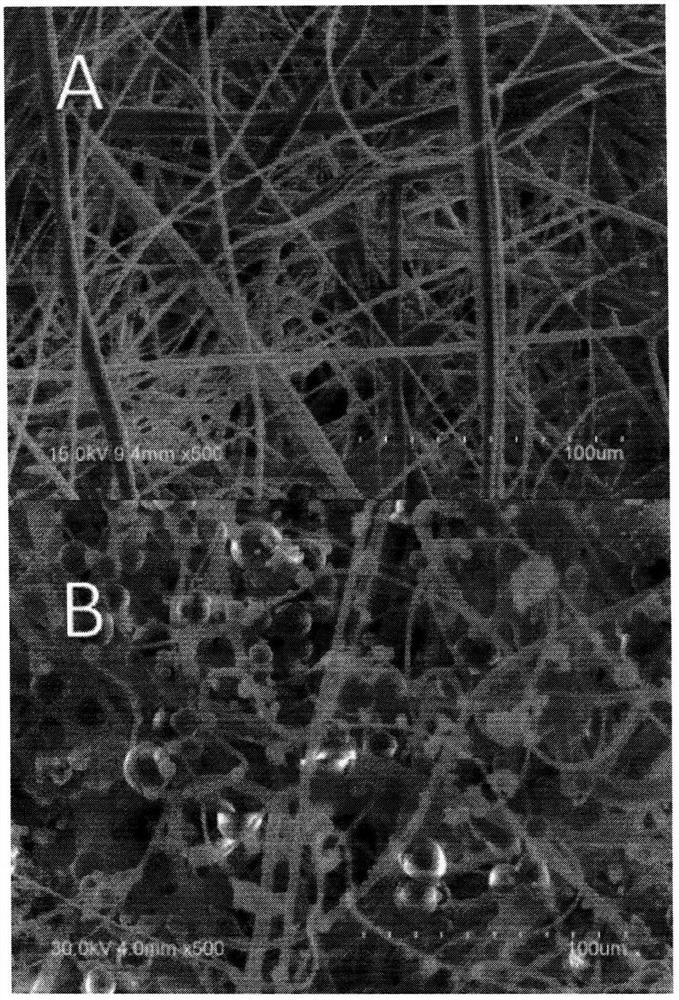

[0034] In the simulated filtration experiment, the single-layer membrane (D-13, D-30 and D-45) should be used according to the shape of the funn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com