Archaized brick prepared by using red mud slag and method thereof

A technology of antique bricks and slag, applied in the field of antique bricks, to reduce damage, avoid cumbersome production processes, and achieve the effect of realistic colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

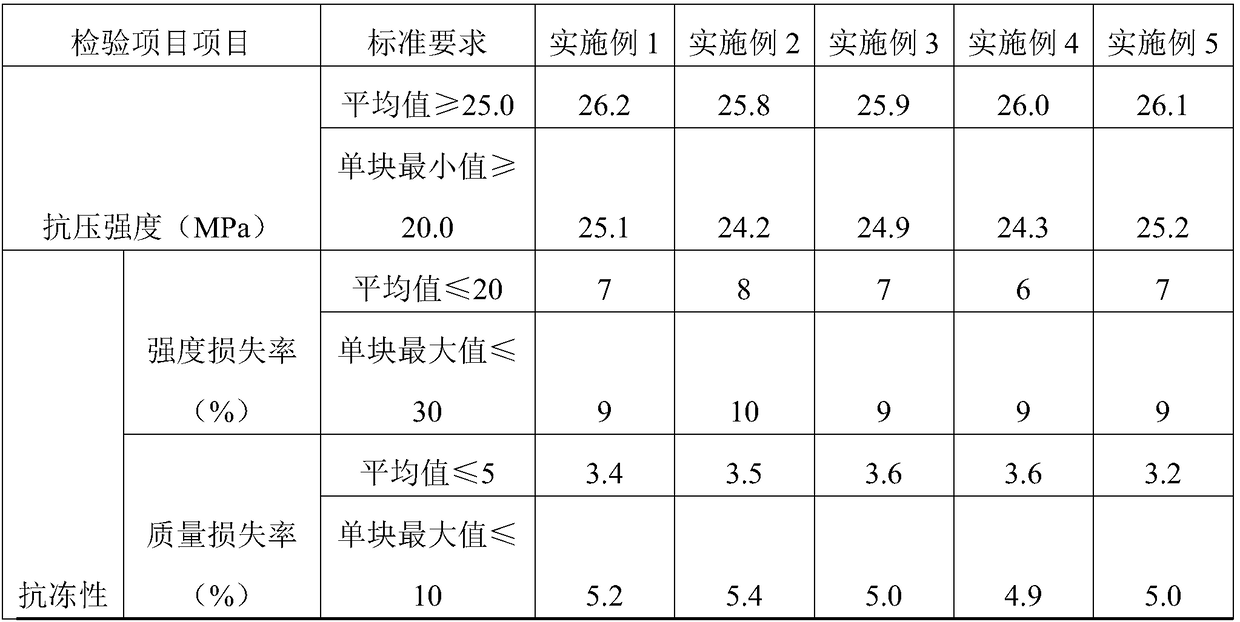

Examples

Embodiment 1

[0024] This example provides an antique brick prepared with red mud slag, which is prepared from the following raw materials in parts by weight: 52 parts of red mud slag, 4 parts of water glass, 20 parts of sludge, 4 parts of salt gypsum, 4 parts of white cement, 3 parts of silicon, 0.8 parts of disodium EDTA, 0.8 parts of sodium sulfate, and 1.7 parts of potassium chloride.

[0025] Wherein, the red mud slag contains 40% of silicon dioxide, 10% of aluminum oxide, 3% of titanium dioxide, and 1.2% of ferrous oxide.

[0026] The present embodiment prepares the method for antique brick with red mud slag, comprises the following steps:

[0027] (1) Crushing and sieving the red mud slag to obtain particles with a particle size of 0.5-1.5 mm for later use;

[0028] (2) Put the sludge into the forced mixer, then add disodium EDTA, after forced stirring for 8 minutes, let it stand for 45 minutes; weigh red mud slag, water glass, salt gypsum, white cement, silica powder, sodium sulfat...

Embodiment 2

[0032] This example provides an antique brick prepared with red mud slag, prepared from the following raw materials in parts by weight: 45 parts of red mud slag, 5 parts of water glass, 15 parts of sludge, 5 parts of salt gypsum, 3 parts of white cement, 4 parts of silica fume, 0.5 part of disodium EDTA, 1.0 part of sodium sulfate, and 1.5 parts of potassium chloride.

[0033] Wherein, the red mud slag contains 30% of silicon dioxide, 18% of aluminum oxide, 2% of titanium dioxide, and 2% of ferrous oxide.

[0034] The present embodiment prepares the method for antique brick with red mud slag, comprises the following steps:

[0035] (1) Crushing and sieving the red mud slag to obtain particles with a particle size of 0.5-1.5 mm for later use;

[0036] (2) Put the sludge into the forced mixer, then add disodium EDTA, after forced stirring for 5 minutes, let it stand for 60 minutes; weigh red mud slag, water glass, salt gypsum, white cement, silica powder, sodium sulfate accordi...

Embodiment 3

[0040] This example provides an antique brick prepared with red mud slag, prepared from the following raw materials in parts by weight: 60 parts of red mud slag, 3 parts of water glass, 25 parts of sludge, 3 parts of salt gypsum, 5 parts of white cement, 2 parts of silica fume, 1.0 parts of disodium EDTA, 0.5 parts of sodium sulfate, and 2.5 parts of potassium chloride.

[0041] Wherein, the red mud slag contains 50% of silicon dioxide, 8% of aluminum oxide, 5% of titanium dioxide, and 0.5% of ferrous oxide.

[0042] The present embodiment prepares the method for antique brick with red mud slag, comprises the following steps:

[0043] (1) Crushing and sieving the red mud slag to obtain particles with a particle size of 0.5-1.5 mm for later use;

[0044] (2) Put the sludge into the forced mixer, then add disodium EDTA, after forced stirring for 10 minutes, let it stand for 30 minutes; weigh red mud slag, water glass, salt gypsum, white cement, silica powder, sodium sulfate acc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com