N-methylpyrrolidone decompression and purification system and purification method

A technology of methylpyrrolidone and purification method, which is applied in N-methylpyrrolidone decompression purification system and purification field, which can solve the problems of large increase in energy consumption of light removal tower, pollution of trays and packing, etc., and reduce maintenance workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

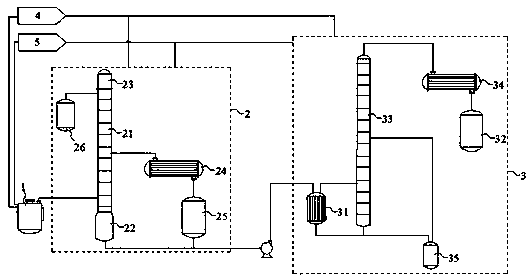

[0027] like figure 1 As shown, the N-methylpyrrolidone decompression purification system of Example 1 is a closed system comprising a feed tank 1, light removal unit 2 and finished product unit 3 connected in sequence;

[0028] The dehydrogenation unit 2 includes a light removal tower 21 and a first reboiler 22 arranged at the bottom of the light removal tower 21, the gas phase feed port of the light removal tower 21 is connected with the gas phase outlet of the feed tank 1, and the light removal tower 21 feeds The top of the mouth is provided with the semi-finished product outlet of the rectification section and the tower top condenser 23, the semi-finished product discharge port communicates with the semi-finished product condenser 24, the liquid outlet of the semi-finished product condenser 24 communicates with the receiving tank 25, and the tower top condenser 23 The distributor below communicates with the light component receiving tank 26;

[0029] Finishing unit 3 compr...

Embodiment 2

[0032] Embodiment 2, the purification system communicates with the nitrogen gas source 5 .

[0033] Specifically, the nitrogen gas supplied by the nitrogen gas source is dry. It is respectively connected with the feed tank, light removal tower, receiving tank, finished product tower and light component receiving tank in the system through pipelines. As an equivalent alternative, dry air can also be used to displace the nitrogen in the system.

[0034] The N-methylpyrrolidone decompression purification method of embodiment 1 comprises the following steps:

[0035] S1: Replace the air in the purification system with nitrogen, start the vacuum pump and maintain the vacuum of the purification system;

[0036] S2: Feeding, heating the raw materials in the feeding tank, and feeding the raw materials through the side line gas phase of the light removal tower after gasification;

[0037]S3: light removal, the first reboiler at the bottom of the light removal tower heats the materia...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap