Mechanochemical preparation method for covalent organic framework material and application

A covalent organic framework and mechanochemical technology, applied in the field of photocatalytic materials, can solve the problems of difficult synthesis of photocatalytic materials, affecting the application efficiency of materials, and the inhomogeneous crystallinity of generated materials, and achieves simple preparation methods and good industrial performance. The effect of applying the foreground and shortening the generation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1 : Preparation of covalent organic framework material TpMA of the present invention

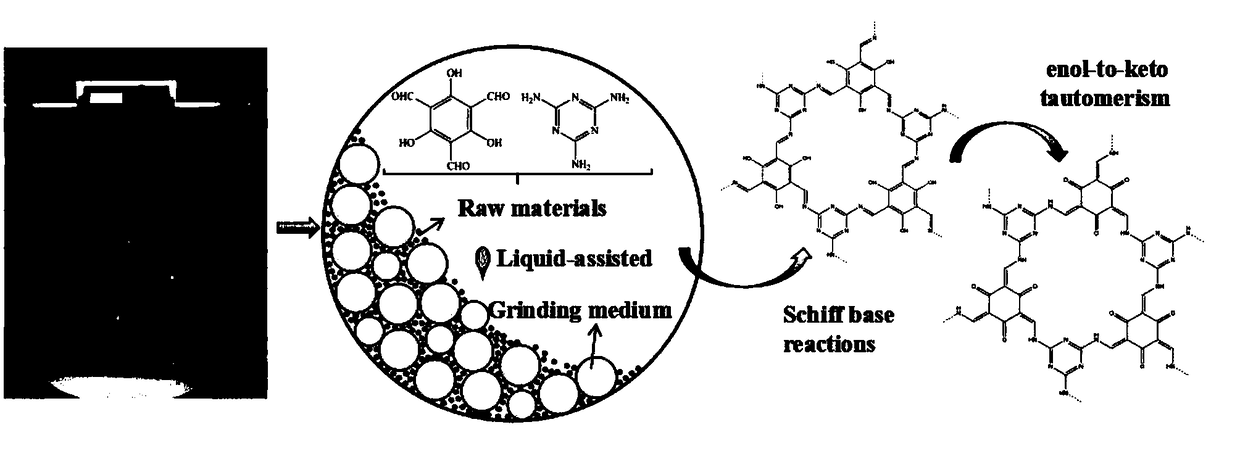

[0041] This embodiment is the preparation of covalent organic framework material TpMA, such as figure 1 Shown, the specific preparation method is:

[0042] Put melamine and 2,4,6-triformylphloroglucinol raw materials into a ball mill reaction kettle, mix well, and then add 3mL p-toluenesulfonic acid. Add the zirconia media pellets used for grinding into the reactor, and the total volume of the media pellets and the mixed raw materials shall not exceed 2 / 3 of the total volume of the reactor. Cover the lid of the reaction kettle, fix the ball mill reaction kettle and cover the outer cover of the ball mill. Set the rotational speed of the ball mill to 300 rpm, set the total grinding time to 3 hours and 12 minutes, and the net ball milling time is 3 hours. After ball milling, the samples were washed with dimethylformamide, acetone and ultrapure water, and then dried in an ove...

Embodiment 2

[0043] Example 2 : Structural characterization of the covalent organic framework material TpMA of the present invention

[0044] This example is the structural characterization of the covalent organic framework material TpMA, specifically as follows:

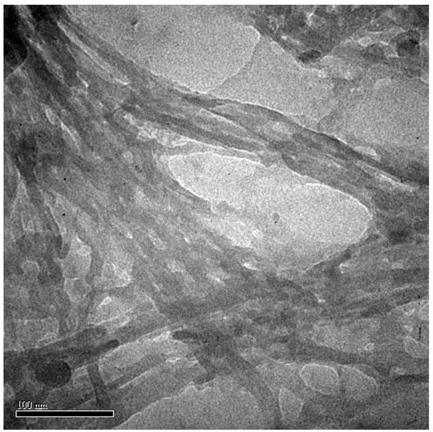

[0045] 1. TEM image

[0046] The morphology and structure of covalent organic framework material TpMA were analyzed by transmission electron microscope Hitachi H-7500: from figure 2 It can be seen that the covalent organic framework material TpMA presents an exfoliated flake-like structure.

[0047] 2. PXRD spectrum

[0048] The X-ray diffraction (XRD) pattern of the covalent organic framework material TpMA was obtained on a PAN-alytical X’Pertdiffractometer, using nickel to filter Cu Kα rays, with a scanning range from 5° to 50° and a scanning speed of 4° / min. Such as image 3 As shown, the covalent organic framework material TpMA has diffraction characteristic peaks at 2θ of 5°, 9.2°, 14.6°, and 26.9°, which are basical...

Embodiment 3

[0055] Example 3 : Catalytic performance test of covalent organic framework material TpMA of the present invention

[0056] In this example, phenol and methyl orange were selected as representatives to test the catalytic performance of the covalent organic framework material TpMA. The test steps are as follows: prepare 50 mL of 10 mg / L phenol and methyl orange dye solutions respectively, put them in a 100 mL beaker, add 30 mg of TpMA photocatalyst sample, and stir for 1 hour in the dark to reach the steady state of adsorption-desorption. Using an Xe lamp as a light source, a 400 nm cut-off glass filter was used to remove wavelengths irrelevant to the experiment, and the solution was irradiated while being magnetically stirred. During the irradiation process, 1.5ml of the solution was taken at regular intervals, and after centrifugation, the supernatant was taken for testing. After the photocatalytic reaction, the TpMA photocatalyst was washed with ultrapure water, dried and...

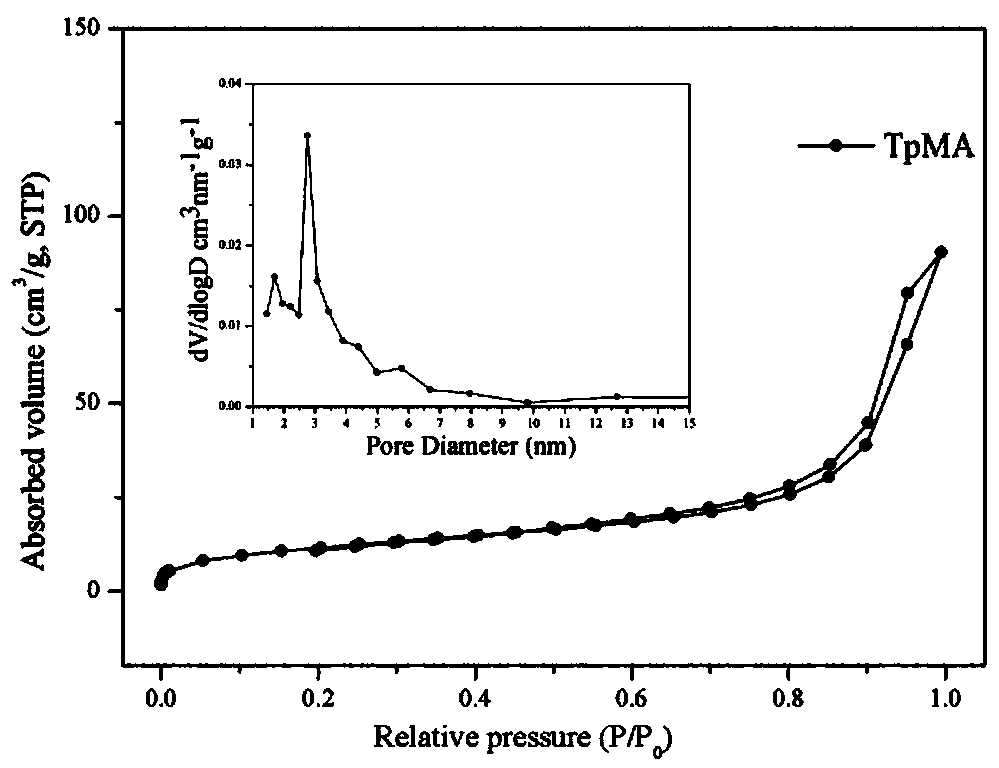

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com