A preparation method of in-situ reaction compatibilization polypropylene/attapulgite composite material

A technology of attapulgite and in-situ reaction, which is applied in the field of preparation of in-situ reaction compatibilized polypropylene/attapulgite composite materials, which can solve the problems of harmfulness to human body, increased process steps, and strong odor of polar monomers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

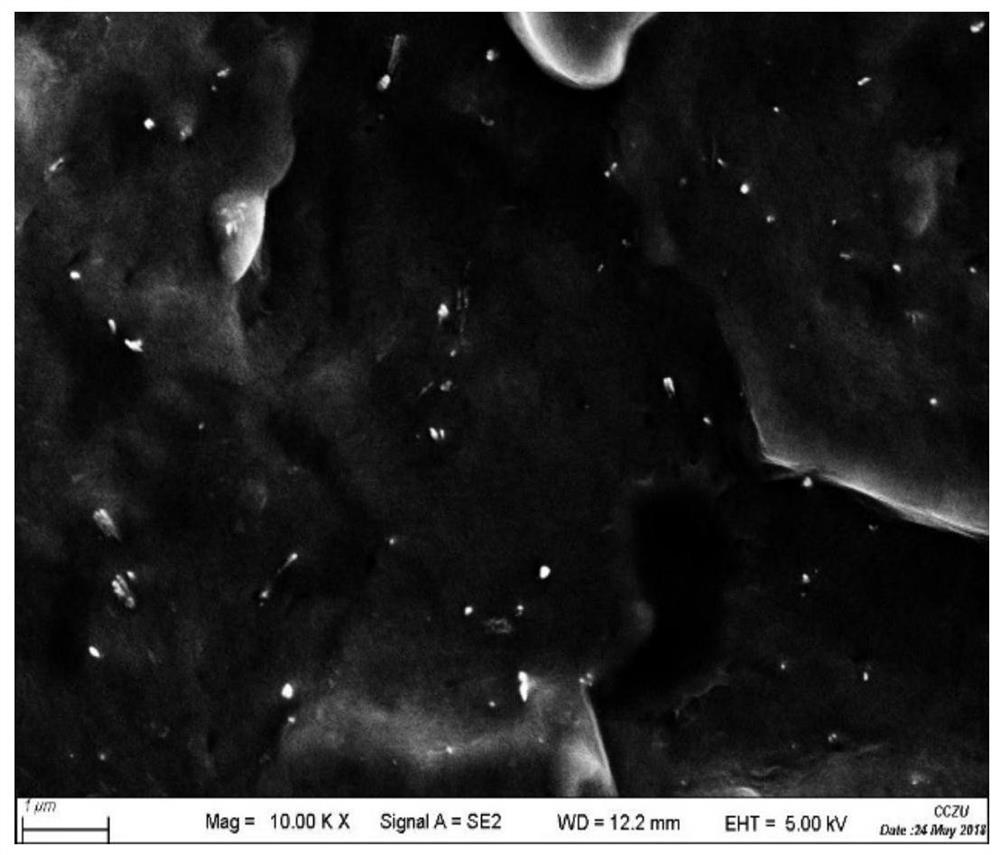

Image

Examples

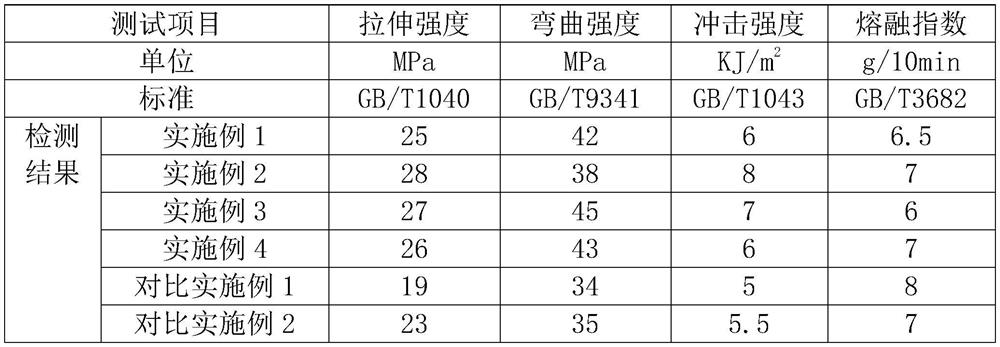

Embodiment 1

[0020] Step 1: Fully mix 50g of attapulgite with 250g of anhydrous ethanol / water mixed solvent with a mass ratio of 9:1 to make a suspension, then add 10g of chloropropyltriethoxysilane and 0.05g of dibutyltin dilaurate , stir evenly at room temperature, then heat up to reflux for 3 hours, centrifuge, wash and dry to obtain chloropropyl-modified attapulgite;

[0021] Step 2: Add 50g of chloropropyl-modified attapulgite to 250g of dioxane again to disperse evenly, add 4.5g of tert-butanol peroxide and 0.08g of ferric chloride at the same time, react at room temperature for 5h, after solid-liquid separation Washing, vacuum drying, and pulverization to obtain attapulgite modified by peroxy groups;

[0022] Step 3: 2500g polypropylene, 50g peroxy group modified attapulgite, 2.5g liquid paraffin, 8g maleic anhydride, 2.5g antioxidant (antioxidant 1010 and antioxidant 168, ratio 1:1) Mix evenly in a mixer, melt extrude and granulate at 200° C. to obtain an in-situ reaction compatib...

Embodiment 2

[0024] Step 1: Fully mix 50g of attapulgite with 500g of ethylene glycol / water mixed solvent with a mass ratio of 8:1 to make a suspension, then add 20g of chloropropyltriethoxysilane and 0.1g of dibutyltin dilaurate , stir evenly at room temperature, then heat up to reflux for 3 hours, centrifuge, wash and dry to obtain chloropropyl-modified attapulgite;

[0025] Step 2: Add 50g of chloropropyl-modified attapulgite to 500g of dioxane to disperse evenly, add 9g of tert-butyl hydroperoxide and 0.2g of ferric chloride at the same time, react at room temperature for 8h, after solid-liquid separation Washing, vacuum drying, and pulverization to obtain attapulgite modified by peroxy groups;

[0026] Step 3: 5000g polypropylene, 50g peroxy group modified attapulgite, 5g silicone oil, 15g glycidyl methacrylate, 5g antioxidant (antioxidant 1010 and antioxidant 168, ratio 1:1) Mix evenly in a mixer, melt extrude and granulate at 210°C to obtain an in-situ reaction compatibilized polyp...

Embodiment 3

[0029] Step 1: Fully mix 50g of attapulgite with 250g of toluene / water mixed solvent with a mass ratio of 8:1 to make a suspension, then add 15g of chloropropyltrimethoxysilane and 0.03g of dioctyltin dilaurate, at room temperature After stirring evenly, heat up to reflux for 5 hours, centrifuge and wash and dry to obtain chloropropyl-modified attapulgite;

[0030] Step 2: Add 50g of chloropropyl-modified attapulgite to 250g of chloroform to disperse evenly, add 6.5g of tert-butanol peroxide and 0.15g of ferric chloride at the same time, react at room temperature for 8h, and wash after solid-liquid separation , pulverized after vacuum drying to obtain attapulgite modified by peroxy groups;

[0031] Step 3: Mix 2500g polypropylene, 50g peroxy group modified attapulgite, 6g PE wax, 8g styrene, 2.5g antioxidant (antioxidant 1010 and antioxidant 168, ratio 1:1.5) The mixture is evenly mixed in the machine, and the in-situ reaction compatibilization polypropylene / attapulgite compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com