High-strength, high-conductivity and bending-resistant graphite foil and preparation method thereof

A technology of graphite foil and graphene, applied in coating and other directions, can solve the problems of graphite foil's high temperature resistance and chemical resistance, low thermal decomposition temperature and chemical instability, sacrificing graphite's electrical conductivity and thermal conductivity, etc. Achieve the effect of good folding capacitor performance, good application prospects, and obvious reduction in ohmic resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

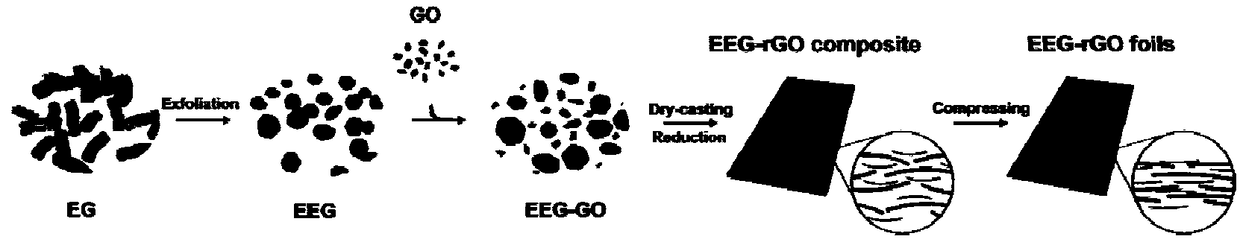

Method used

Image

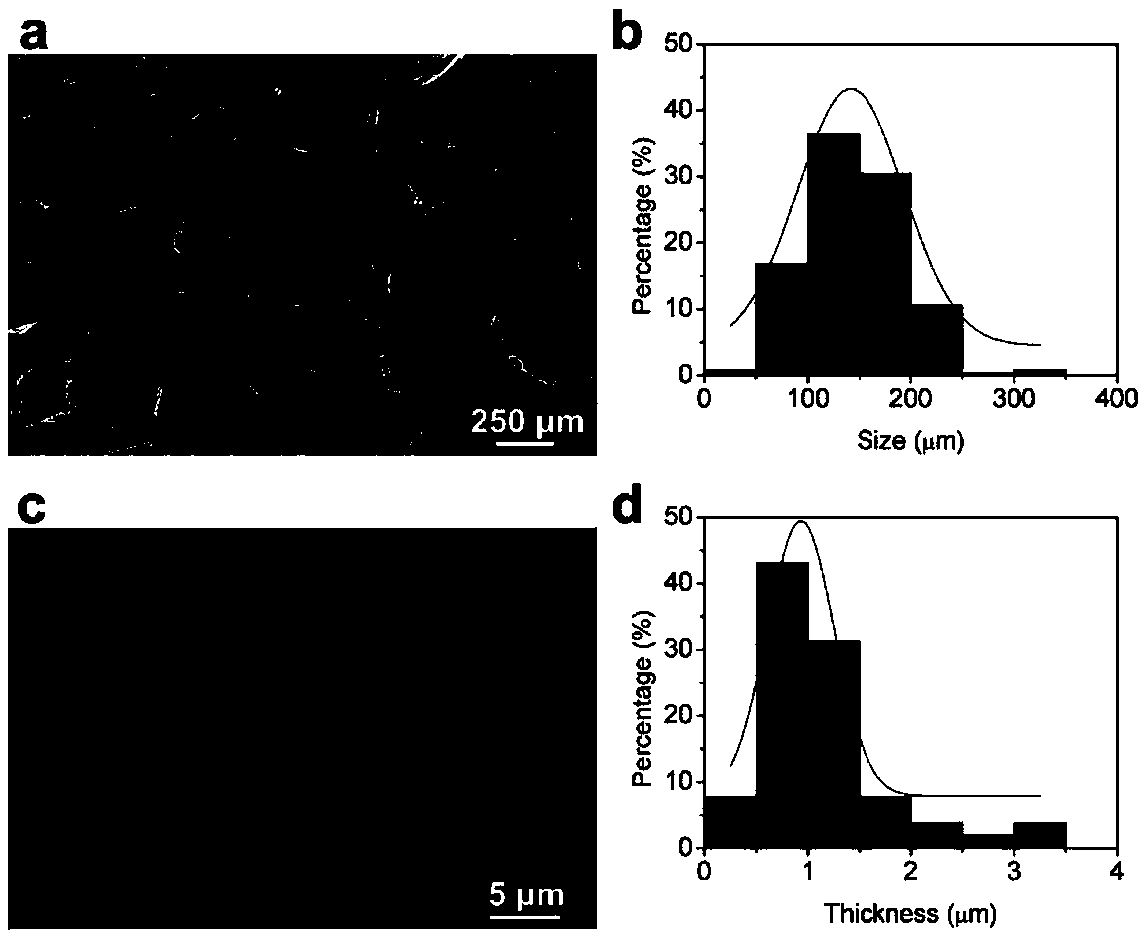

Examples

Embodiment 1

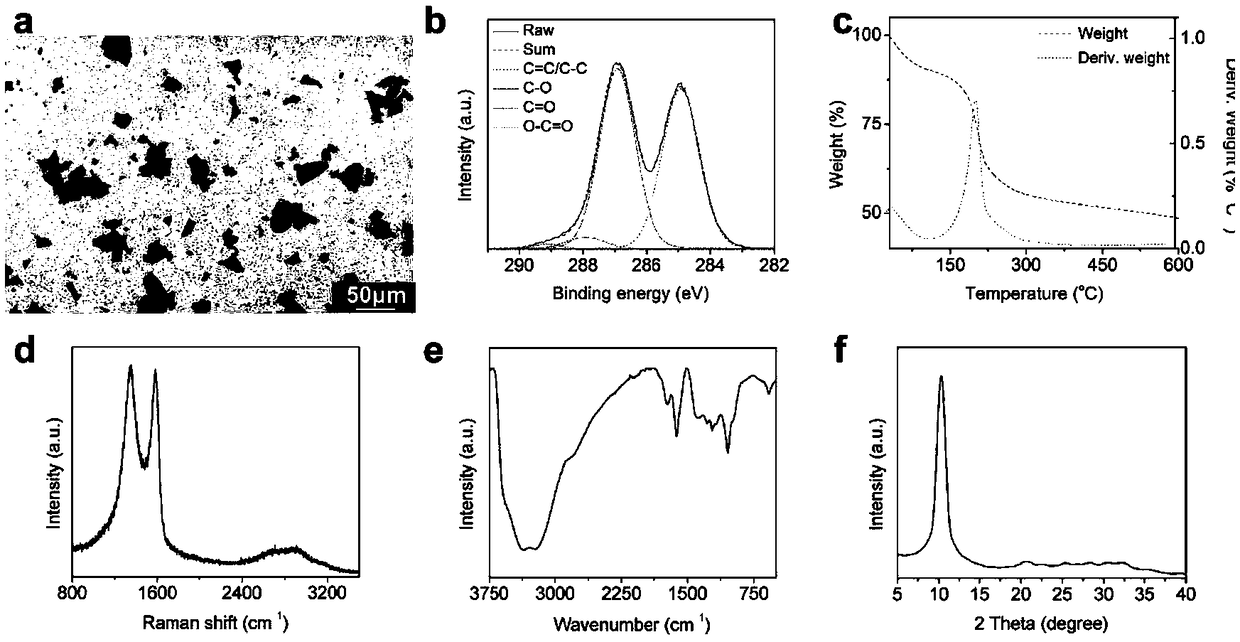

[0049]Preparation of graphene oxide: Add 3.0g 325 mesh flake graphite powder into a 500mL flask, slowly add 138mL 98wt% concentrated sulfuric acid in 12mL deionized water, mix well and cool to room temperature, slowly add diluted concentrated sulfuric acid into the 500mL flask , keep stirring while controlling the temperature of the reaction system to always be lower than 5°C. Under the condition of keeping stirring, slowly add 9.0g potassium permanganate powder, this process lasts for 2 hours, control the system temperature below 5°C, and continue the reaction for 48 hours, pour the above reaction mixture system into the ice-water mixing bath to terminate the reaction , under the condition of keeping stirring, slowly add 30wt% hydrogen peroxide aqueous solution dropwise until no bubbles are generated. At this moment, the solution turned from brown to yellow, and the above-mentioned yellow solution was vacuum filtered, and the resulting filter cake was washed with 500 mL of di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com