Epoxy resin acrylic ester copolymerization pressure-sensitive adhesive and preparation method thereof

An epoxy resin and acrylate technology, applied in adhesives, polyurea/polyurethane adhesives, adhesive types, etc., can solve problems such as large environmental pollution, and achieve the effects of low price, good emulsification effect and wide supply.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

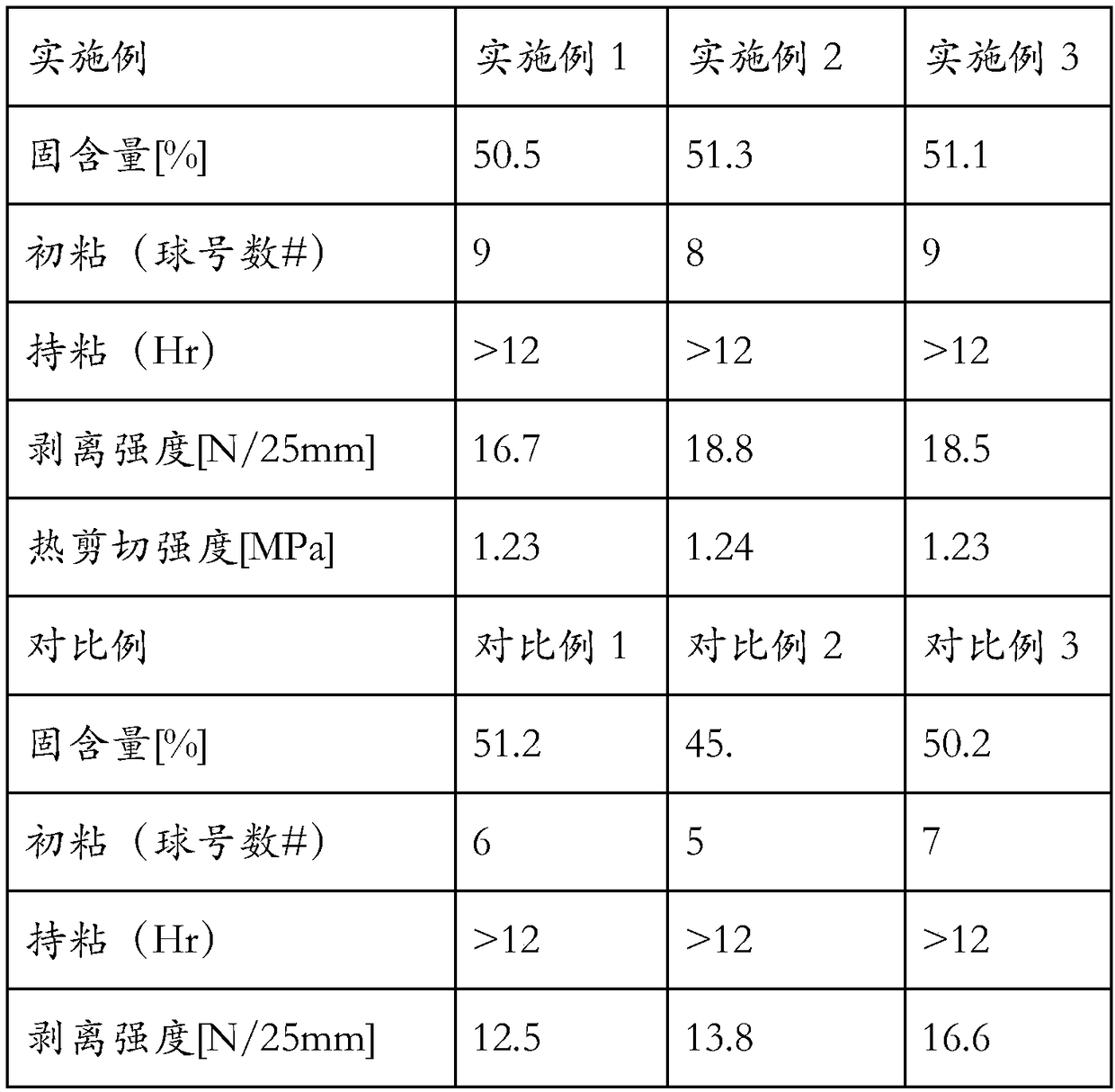

Embodiment 1

[0051] An epoxy resin acrylate copolymerized pressure-sensitive adhesive, made of the following components by weight: 15 parts of methyl methacrylate (MMA); 14 parts of vinyl acetate; 24 parts of ethyl acrylate; 28 parts of acrylic acid Butyl ester (BA); 30 parts of epoxy resin E-44, 0.75 parts of composite emulsifier; 1 part of ammonium persulfate, 11 parts of isocyanate and 0.48 parts of triethylamine; the composite emulsifier consists of potassium stearate and polystearic acid Oxyethylene esters are composed at a weight ratio of 1:1;

[0052] The method for preparing this epoxy resin acrylate copolymerized pressure-sensitive adhesive comprises the following steps:

[0053] (1) Add 500g water, 150g methyl methacrylate, 140g vinyl acetate, 240g ethyl acrylate, 280g butyl acrylate, 300g epoxy resin E-44 and 1.5g composite emulsifier in the first reaction kettle, 30min Stir and heat up to 105°C;

[0054] (2) Add 500g of water and 6g of composite emulsifier to the second react...

Embodiment 2

[0058] An epoxy resin acrylate copolymerized pressure-sensitive adhesive, made of the following components by weight: 13.5 parts of methyl methacrylate (MMA); 16.5 parts of vinyl acetate; 20.5 parts of ethyl acrylate; 31.5 parts of acrylic acid Butyl ester (BA); 25 parts of epoxy resin E-44, 0.5 part of composite emulsifier; 0.5 part of ammonium persulfate, 15 parts of isocyanate and 0.24 part of triethylamine; composite emulsifier consists of potassium abietate and polyoxyethylene abietate Esters are composed at a weight ratio of 1:1;

[0059] The method for preparing this epoxy resin acrylate copolymerized pressure-sensitive adhesive comprises the following steps:

[0060] (1) Add 500g water, 135g methyl methacrylate, 165g vinyl acetate, 205g ethyl acrylate, 315g butyl acrylate, 250g epoxy resin and 1g composite emulsifier in the first reactor, stir and heat up to within 30min 105°C;

[0061] (2) Add 500g of water and 4g of composite emulsifier to the second reactor under ...

Embodiment 3

[0065] An epoxy resin acrylate copolymerized pressure-sensitive adhesive, made of the following components by weight: 18.5 parts of methyl methacrylate (MMA); 12.5 parts of vinyl acetate; 27.5 parts of ethyl acrylate; 25.5 parts of acrylic acid Butyl ester (BA); 35 parts of epoxy resin E-44, 1 part of composite emulsifier; 1.5 parts of ammonium persulfate, 7 parts of isocyanate and 0.24 part of triethylamine; composite emulsifier consists of potassium abietate and polyoxyethylene abietic acid Esters are composed at a weight ratio of 1:1;

[0066] The method for preparing this epoxy resin acrylate copolymerized pressure-sensitive adhesive comprises the following steps:

[0067] (1) add 500g water, 185g methyl methacrylate, 125g vinyl acetate, 275g ethyl acrylate, 350g butyl acrylate, 350g epoxy resin and 4g composite emulsifier in the first reactor, stir and heat up to within 30min 105°C;

[0068] (2) Add 500g of water and 6g of composite emulsifier to the second reactor unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com