Gaseous mercury concentration detection device and method on basis of ring resonator frequency doubling structure

A ring resonant cavity and concentration detection technology, applied in the detection field, can solve the problems of low frequency doubling efficiency and low measurement signal-to-noise ratio, and achieve the effects of improving frequency doubling efficiency, expanding the selection range, and enhancing the fundamental frequency optical power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

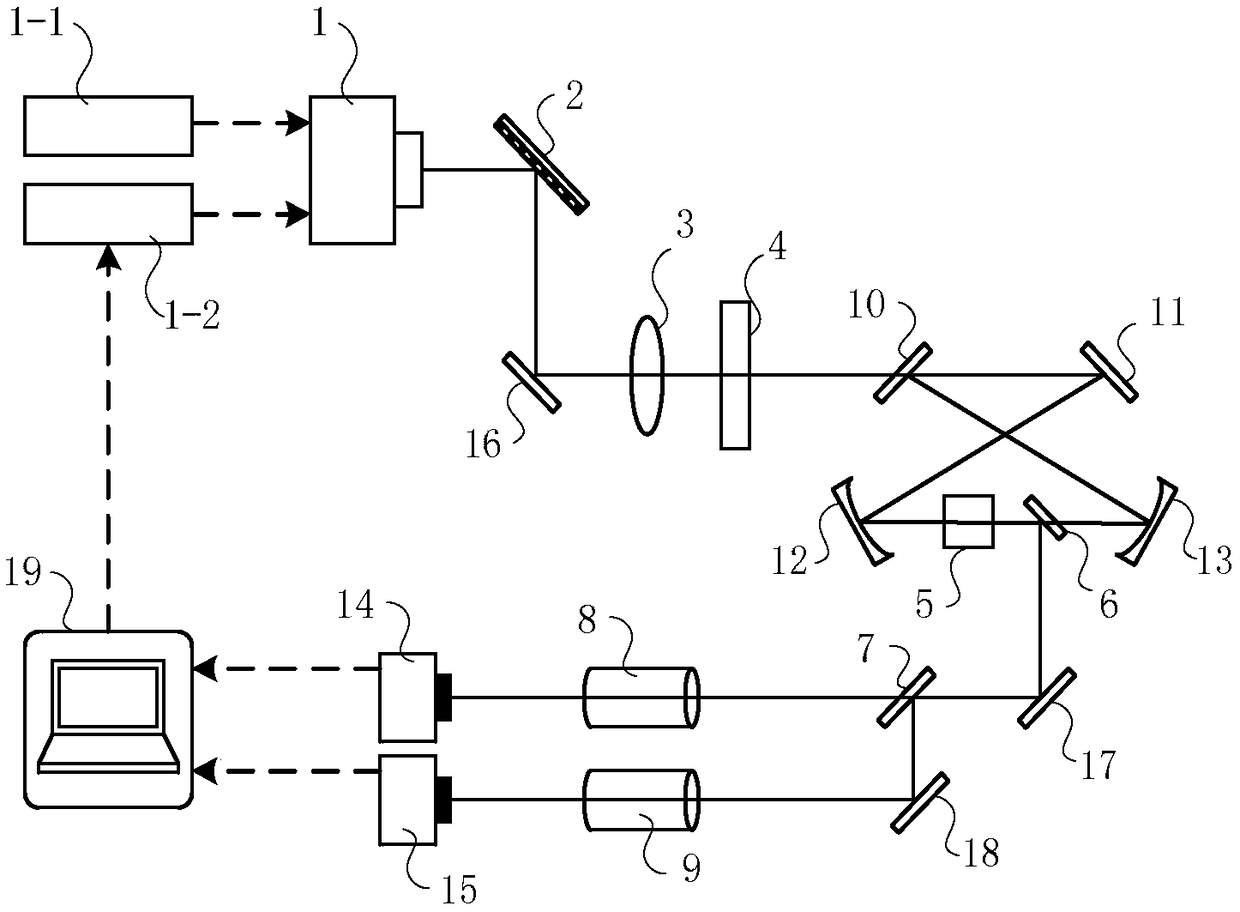

[0029] Such as figure 1 As shown, the gaseous mercury concentration detection device semiconductor laser 1, grating 2, mode matching mirror 2, half-wave plate 4, ring resonator, BBO crystal 5, dichroic mirror 6, beam splitter 7, reference gas chamber 8, detection Gas chamber 9, three mirrors and two detectors.

[0030] The output wavelength of the semiconductor laser 1 is 507.3±2 nm or 730.2±2 nm, and the output light intensity is greater than or equal to 10 mW. The output optical path of the semiconductor laser 1 is provided with a grating 2, a first reflection mirror 16, a mode matching mirror 3, a half-wave plate 4, a coupling mirror 10, a first high reflection mirror 11, a second high reflection mirror 12, and a third high reflection mirror. Mirror 13.

[0031] The output wavelength of the semiconductor laser 1 is adjusted by adjusting the angle of the grating to achieve feedback adjustment, which can reach 507.3 nanometers or 730.2 nanometers accurately. The light beam...

Embodiment 2

[0044] The output wavelength of the semiconductor laser 1 is 505 nanometers, and the output light intensity is 35 milliwatts. The output wavelength of the laser can be adjusted to 507.3 nanometers by adjusting the grating angle to achieve feedback adjustment. The length of the reference air chamber is 1 mm, and the internal mercury vapor concentration is converted by the ambient temperature. When the ambient temperature is 20 degrees Celsius, the internal mercury vapor concentration is 14.066ng / cm 3 . The detection chamber length is 200 cm. The gas to be tested flows into the detection gas chamber through the gas pipe.

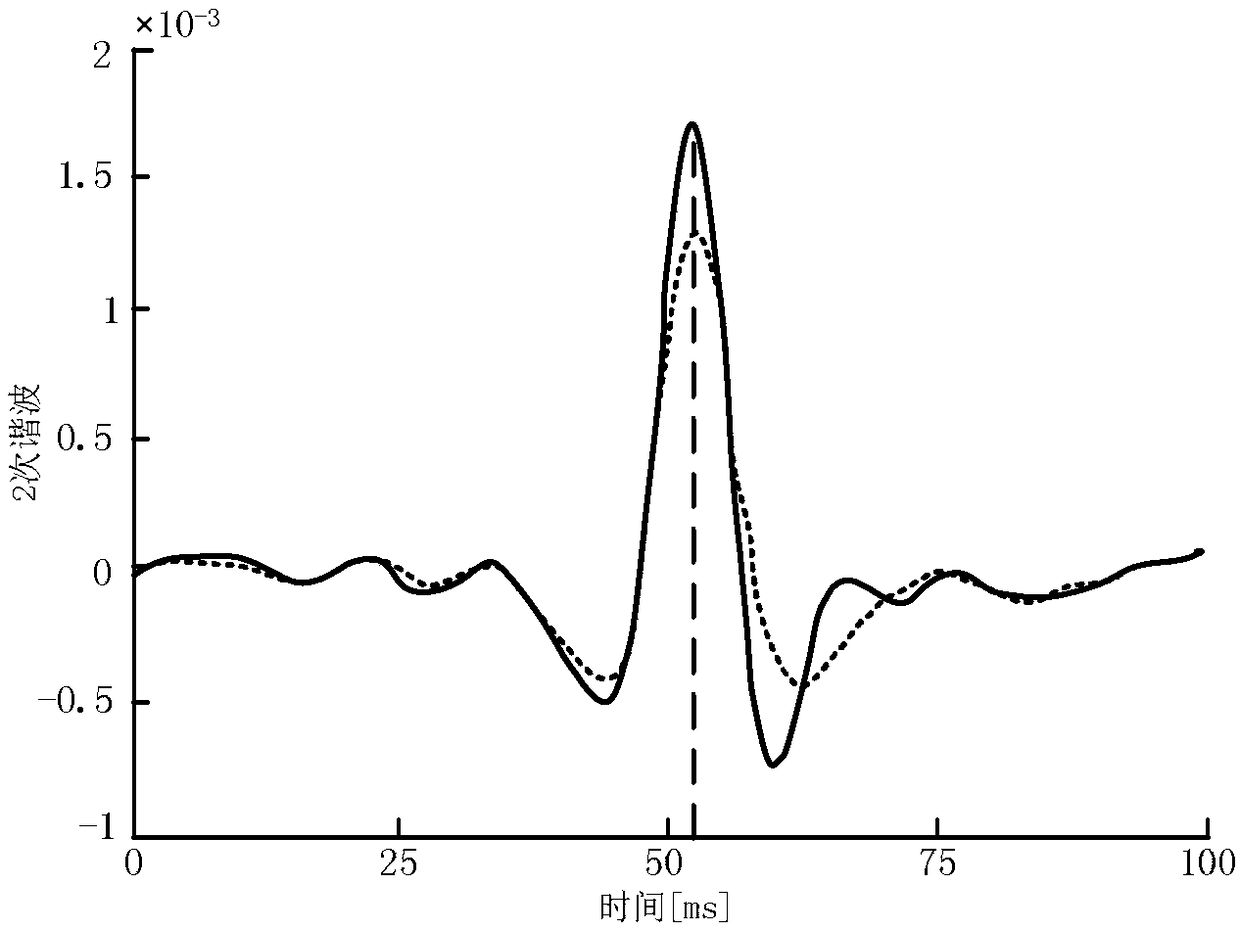

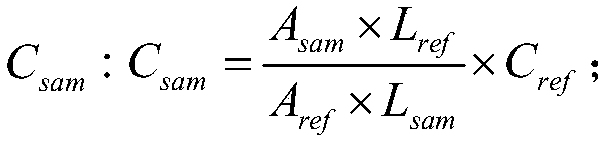

[0045] After processing through lock-in amplification, it is obtained as figure 2 The 2nd harmonic signal shown. Wherein, the dotted line is the signal of the reference road, and the solid line is the signal of the road to be tested. It can be seen from the figure that the maximum amplitude A of the second harmonic signal appears on the reference circuit ...

Embodiment 3

[0047] The output wavelength of the semiconductor laser 1 is 730 nanometers, and the output light intensity is 10 milliwatts. The output wavelength of the laser is adjusted by feedback by adjusting the angle of the grating to make it accurate to 730.2 nanometers. The length of the reference air chamber is 4 mm, and the internal mercury vapor concentration is converted by the ambient temperature. When the ambient temperature is 25 degrees Celsius, the internal mercury vapor concentration is 21.1445ng / cm 3 . The detection chamber length is 100 cm. The gas to be tested flows into the detection gas chamber through the gas pipe.

[0048] After being processed by phase-locked amplification, the 2nd harmonic signal is obtained. The reference path signal is 0.0006, and the sample path signal is 0.0002. The amplitude of the two signals is calculated by the formula described in the technical plan, and the concentration of the gaseous element mercury to be detected is calculated as 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com