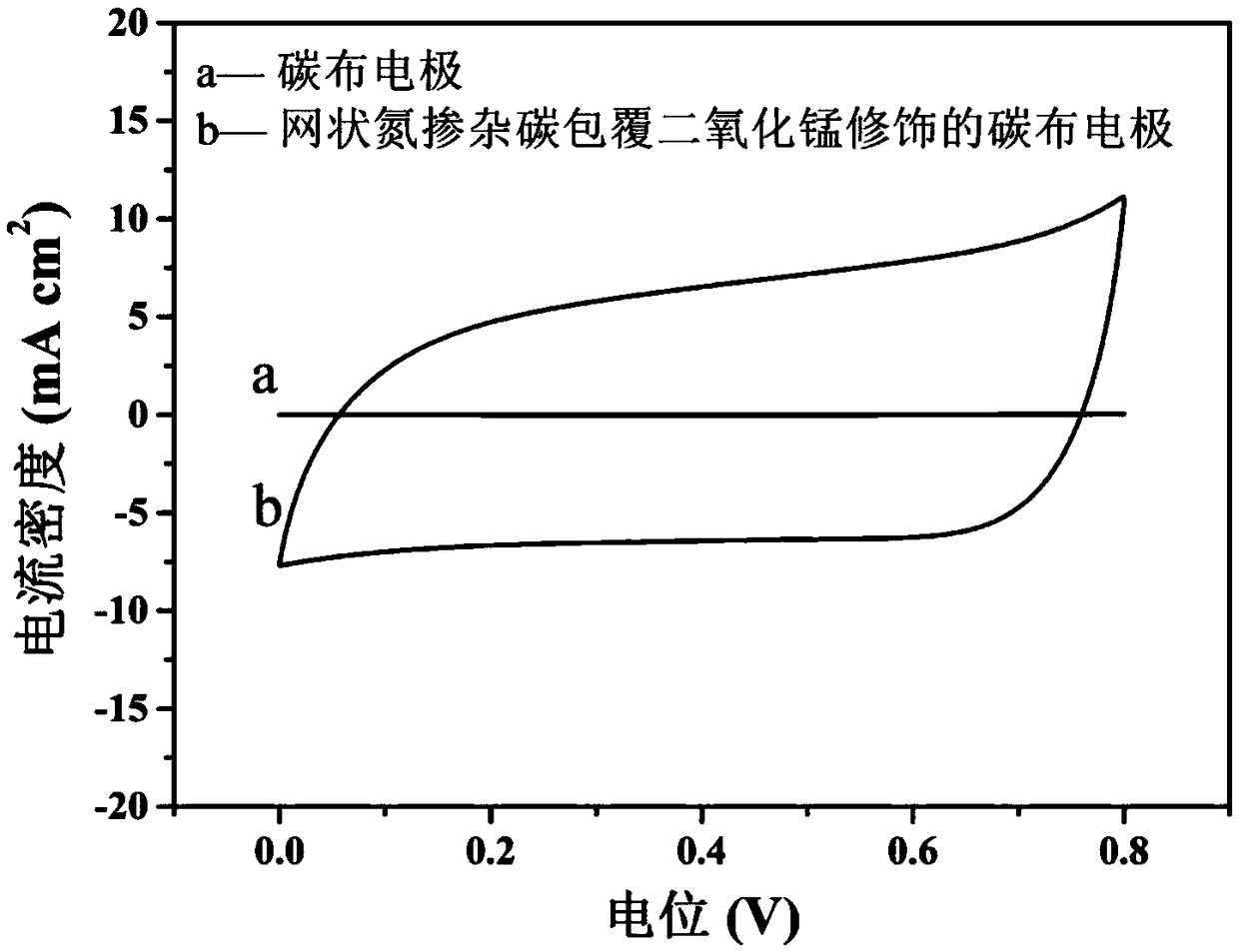

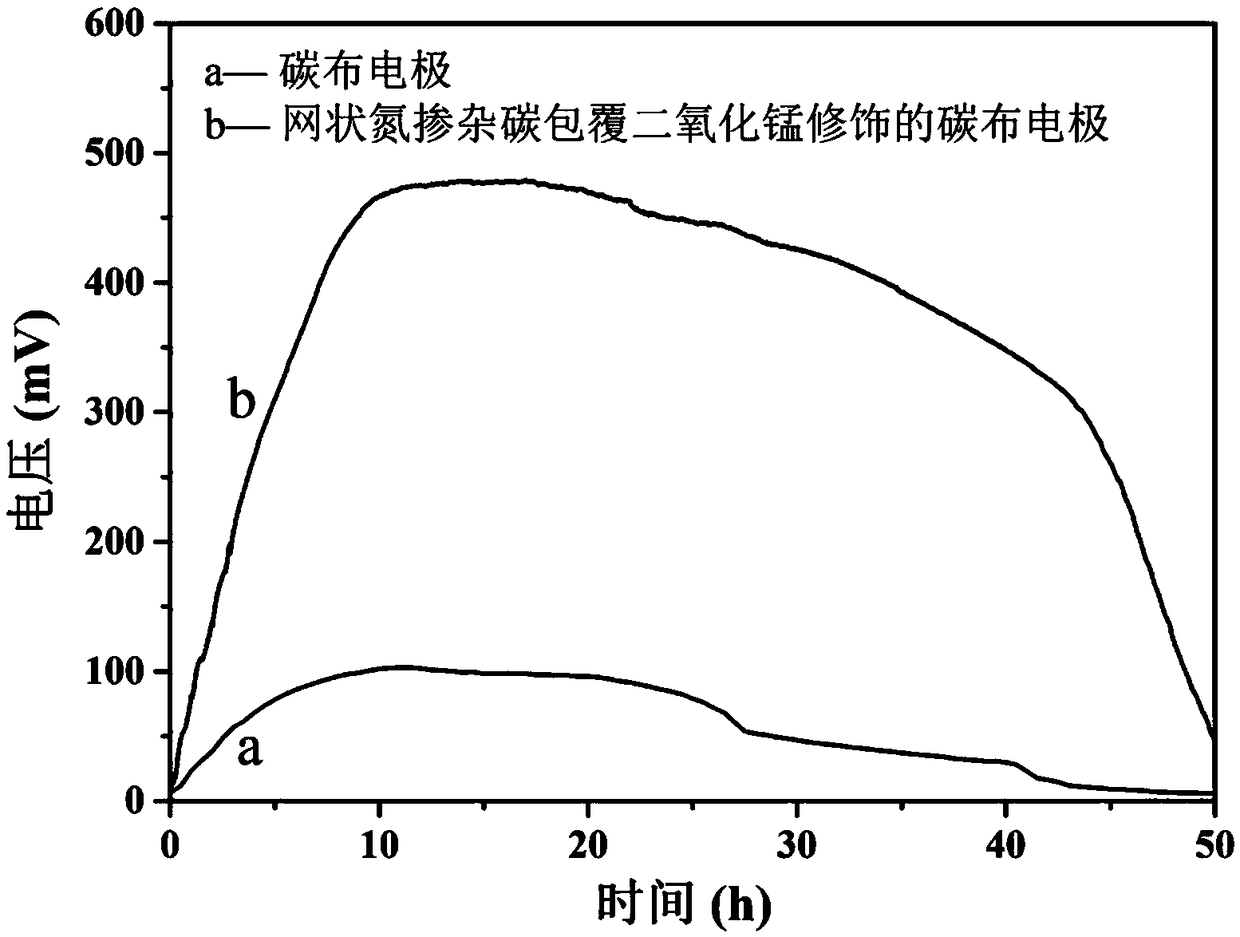

Reticulated nitrogen-doped carbon-coated manganese dioxide carbon cloth electrode and preparation method and application thereof

A technology of manganese dioxide carbon cloth and nitrogen-doped carbon, which is applied in battery electrodes, biochemical fuel cells, circuits, etc., can solve the problems of complex graphene preparation, high cost, and poor biocompatibility, and achieve low electrode cost, Improve performance, performance-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Preparation of carbon cloth electrode modified by manganese dioxide-coated network nitrogen-doped carbon:

[0021] A Cut the purchased commercial carbon cloth into a size of 1cm×2cm, and then assemble it with a 12cm titanium wire to form an electrode, immerse it in deionized water and ultrasonicate for 30min to drive away the air bubbles on the surface. Formulated with 0.0125M MnSO 4 , 0.25M NaAc and 0.125M (NH 4 ) 2 SO 4 The mixed solution of MnO was grown on carbon fibers by three-electrode system electrochemical deposition method 2 nanowire. Among them, the carbon cloth electrode connected with titanium wire was used as the working electrode, the platinum wire was used as the counter electrode, and the saturated calomel electrode was used as the reference electrode. During the electrodeposition process, the voltage was kept at 0.92V, and the deposition was 60min. MnO 2 After deposition, rinse with deionized water and dry.

[0022] B formulation contains 0.2M ...

Embodiment 2

[0026] A Cut the purchased commercial carbon cloth into a size of 1cm×2cm, and then assemble it with a 12cm titanium wire to form an electrode, immerse it in deionized water and ultrasonicate for 30min to drive away the air bubbles on the surface. Formulated with 0.0188M MnSO 4 , 0.25M NaAc and 0.125M (NH 4 ) 2 SO 4 The mixed solution of MnO was grown on carbon fibers by three-electrode system electrochemical deposition method 2 nanowire. Among them, the carbon cloth electrode connected with titanium wire was used as the working electrode, the platinum wire was used as the counter electrode, and the saturated calomel electrode was used as the reference electrode. During the electrodeposition process, the voltage was kept at 0.92V, and the deposition was 120min. MnO 2 After deposition, rinse with deionized water and dry.

[0027] B formulation contains 0.2M NaClO 4 And the volume ratio is 8% pyrrole monomer solution. In a similar way to MnO 2 The polypyrrole thin film...

Embodiment 3

[0030] A Cut the purchased commercial carbon cloth into a size of 1cm×2cm, and then assemble it with a 12cm titanium wire to form an electrode, immerse it in deionized water and ultrasonicate for 30min to drive away the air bubbles on the surface. Formulated with 0.025M MnSO 4 , 0.25M NaAc and 0.125M (NH 4 ) 2 SO 4 The mixed solution of MnO was grown on carbon fibers by three-electrode system electrochemical deposition method 2 nanowire. Among them, the carbon cloth electrode connected with titanium wire was used as the working electrode, the platinum wire was used as the counter electrode, and the saturated calomel electrode was used as the reference electrode. During the electrodeposition process, the voltage was kept at 0.92V, and the deposition was 180min. MnO 2 After deposition, rinse with deionized water and dry.

[0031] B formulation contains 0.2M NaClO 4 And a 10% pyrrole monomer solution by volume. In a similar way to MnO 2 The polypyrrole thin film was ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com