MBR wastewater treatment system with deep denitrification and dephosphorization functions

A sewage treatment system and deep denitrification technology, applied in the field of MBR sewage treatment system, can solve the problems of high energy consumption of aerobic MBR operation and release of total nitrogen, so as to avoid the increase of effluent TN, alleviate slow membrane pollution, and improve the quality of effluent Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

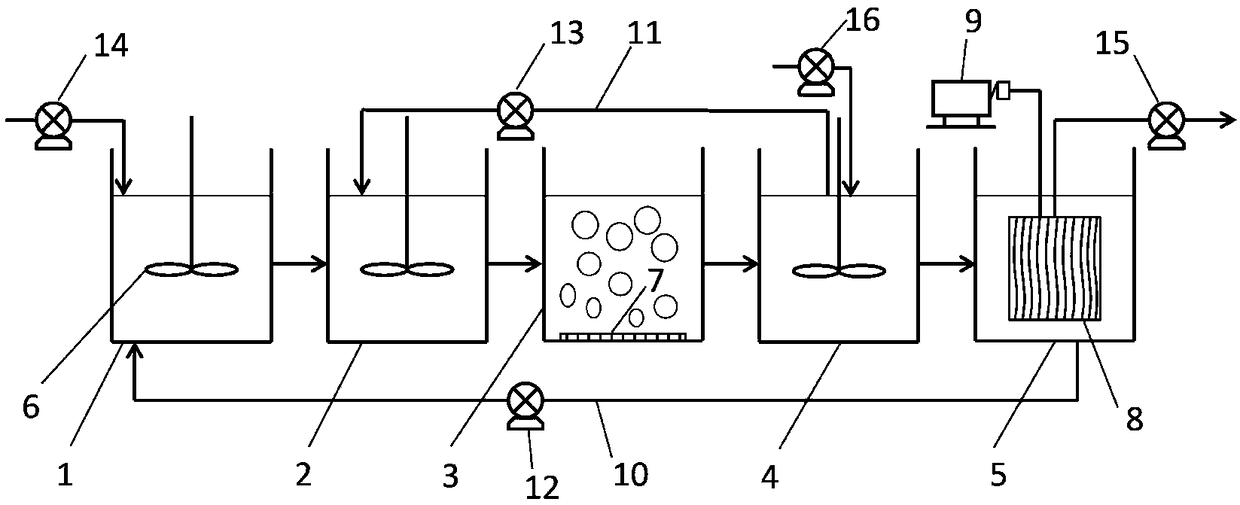

[0033] Such as figure 1 The system shown consists of sequentially connected anaerobic tank 1, front anoxic tank 2, aerobic tank 3, rear anoxic tank 4 and membrane tank 5, where anaerobic tank 1, front anoxic tank 2 and rear anoxic Stirring devices 6 are respectively arranged in the tank 4 , aeration devices 7 are arranged in the aerobic tank 3 , and membrane stack devices 8 are arranged in the membrane tank 5 .

[0034] The membrane stacker 8 realizes horizontal reciprocating movement by setting the pull rod connected to the membrane stacker and the motor 9, the reciprocating motion of the membrane stacker relieves the membrane fouling, and avoids setting an aeration device in the membrane pool 5, thereby reducing the dissolution rate in the membrane pool oxygen concentration.

[0035] The membrane tank 5 and the anaerobic tank 1 are provided with a 1# sludge mixed liquid return pipe 10, and a 1# return pump 12 is arranged on the pipeline of the 1# sludge mixed liquid return ...

Embodiment 2

[0044] During operation, the influent COD concentration is 150-200mg / L, TN concentration is 30-35mg / L, TP concentration is 3-5mg / L, ammonia nitrogen concentration is about 30mg / L, and the TP concentration reaches 10mg / L, a small amount of nitrate nitrogen returned by the membrane pool is also denitrified. The front anoxic tank is the main denitrification and denitrification unit. The carbon source in the raw sewage and the nitrate nitrogen returned by the rear anoxic tank are removed under the action of denitrifying bacteria. The return flow can be controlled to ensure the nitrification of the front anoxic tank Nitrogen is sufficient to ensure full utilization of raw sewage carbon sources. Then the mixed solution enters the aerobic unit, and the dissolved oxygen concentration in the aerobic tank can reach 0.5mg / L. The nitrifying bacteria use oxygen to completely oxidize the ammonia nitrogen in the raw sewage into nitrate nitrogen, and the amount of aeration can be controlled t...

Embodiment 3

[0046] Influent COD concentration is 150-200mg / L, TN concentration is 30-35mg / L, TP concentration is 3-5mg / L, ammonia nitrogen concentration is about 30mg / L, sewage passes through anaerobic, pre-anoxic and aerobic units After the action, the concentration of nitrate nitrogen flowing into the anoxic pool is about 5-7mg / L. In order to achieve a higher effluent water quality goal, the carbon source dosing pump outside the anoxic pool is turned on to control a reasonable dosing amount and further denitrification The role is to remove the nitrate nitrogen in the rear anoxic pool, and increase the backflow flow from the rear anoxic pool to the forward anoxic pool to ensure the concentration of nitrate nitrogen in the front anoxic pool. The removal concentrations of TN in each biochemical unit were 1~2, 16~18, 0~1, 11~13, 2~3 mg / L, the removal amount of ΔTN was about 35 mg / L, and the TN removal load of the anoxic pool increased To 30~35mgN / gVSS·d, to achieve effluent TN<1mg / L.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com