Method for producing graphite extruded plastic plate with CO2 foaming agent

A foaming agent and extruded board technology, which is used in the production of graphite extruded boards by using CO2 foaming agent, can solve the problems that the thermal conductivity of compressive strength needs to be improved, the combustion performance can only reach B2 level, and the stability performance is poor. The effect of eliminating fire hazards, enhancing competitiveness and improving sheet performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A CO 2 Foaming agent produces the method for graphite extruded plate, it may further comprise the steps:

[0029] 1) Weigh each raw material in parts by weight for later use: 30 parts of graphite polystyrene particles, 62 parts of ordinary polystyrene particles, CO 2 3 parts of foaming agent, 2 parts of nucleating agent, 3 parts of flame retardant;

[0030] The nucleating agent is aluminum oxide, and the flame retardant is melamine.

[0031] 2) Put graphite polystyrene particles, ordinary polystyrene particles, nucleating agent and flame retardant into the extruder through the feeder, and inject CO after fully plasticizing in the extruder 2 The foaming agent is fully mixed and cooled and extruded through the mold. After the mold is extruded, the pressure is released quickly, and the foaming agent wrapped in plastic expands rapidly to form closed cells. Under the action of the cells, polystyrene plastic forms The foam board with honeycomb-shaped closed cells is shaped...

Embodiment 2

[0035] A CO 2 Foaming agent produces the method for graphite extruded plate, it may further comprise the steps:

[0036] 1) Weigh each raw material in parts by weight for later use: 25 parts of graphite polystyrene particles, 68 parts of ordinary polystyrene particles, CO 2 2.5 parts of foaming agent, 1 part of nucleating agent, 3.5 parts of flame retardant;

[0037] 2) Put graphite polystyrene particles, ordinary polystyrene particles, nucleating agent and flame retardant into the extruder through the feeder, and inject CO after fully plasticizing in the extruder 2 The foaming agent is fully mixed and cooled and extruded through the mold. After the mold is extruded, the pressure is released quickly, and the foaming agent wrapped in plastic expands rapidly to form closed cells. Under the action of the cells, polystyrene plastic forms The foam board with honeycomb-shaped closed cells is shaped into the required thickness and width by a shaping tractor, and then cut and shaped...

Embodiment 3

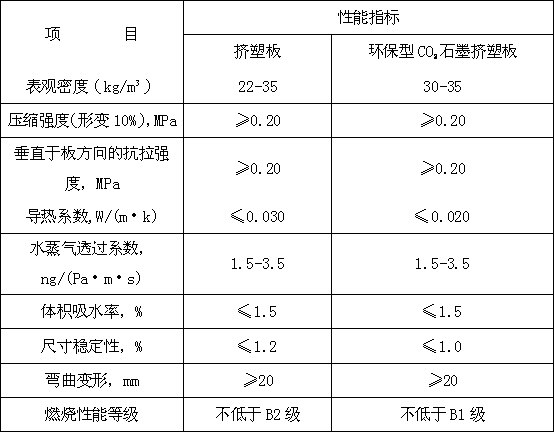

[0041] The main technical indicators of the graphite extruded board of the present invention:

[0042] Take the extruded board used in the market as an example, the comparative data are shown in Table 1:

[0043] Table 1

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com