Anti-precipitation plant fiber modified polypropylene composite material and preparation method thereof

A plant fiber and composite material technology, which is applied in the field of anti-precipitation plant fiber modified polypropylene composite material and its preparation, can solve the problems of poor compatibility and inability to strengthen polypropylene, so as to maintain the fiber structure and reduce material costs , Improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

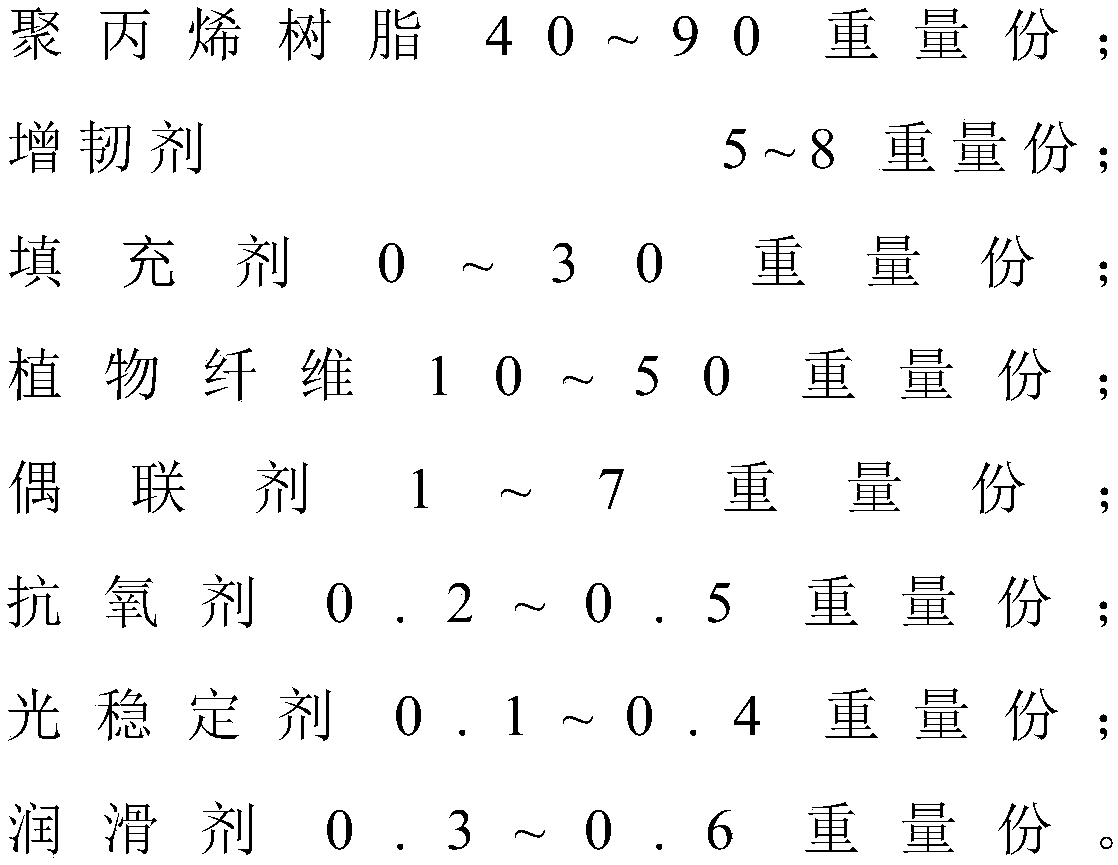

[0028] The present invention also provides a preparation method of anti-separation plant fiber modified polypropylene composite material, comprising the following steps:

[0029] Add polypropylene resin, toughener, coupling agent, antioxidant, light stabilizer and lubricant into the twin-screw extruder through the main feeding hopper, and plant fiber and filler into the twin-screw extruder through the side feeding hopper In the process, pellets are obtained by melting, extrusion, pelletizing and drying.

[0030] Under optimal conditions, the melt extrusion process is as follows: twin-screw extruder barrel temperature is 190-210°C, screw speed is 400-450r / min, host speed is 18-20Hz, vacuum degree -0.06-0.08MPa .

[0031] In the invention, the plant fiber and the filler are fed into the screw extruder in a side-feeding manner, which can well maintain the fiber structure of the plant fiber, thereby improving the mechanical properties of the polypropylene composite material.

Embodiment 1

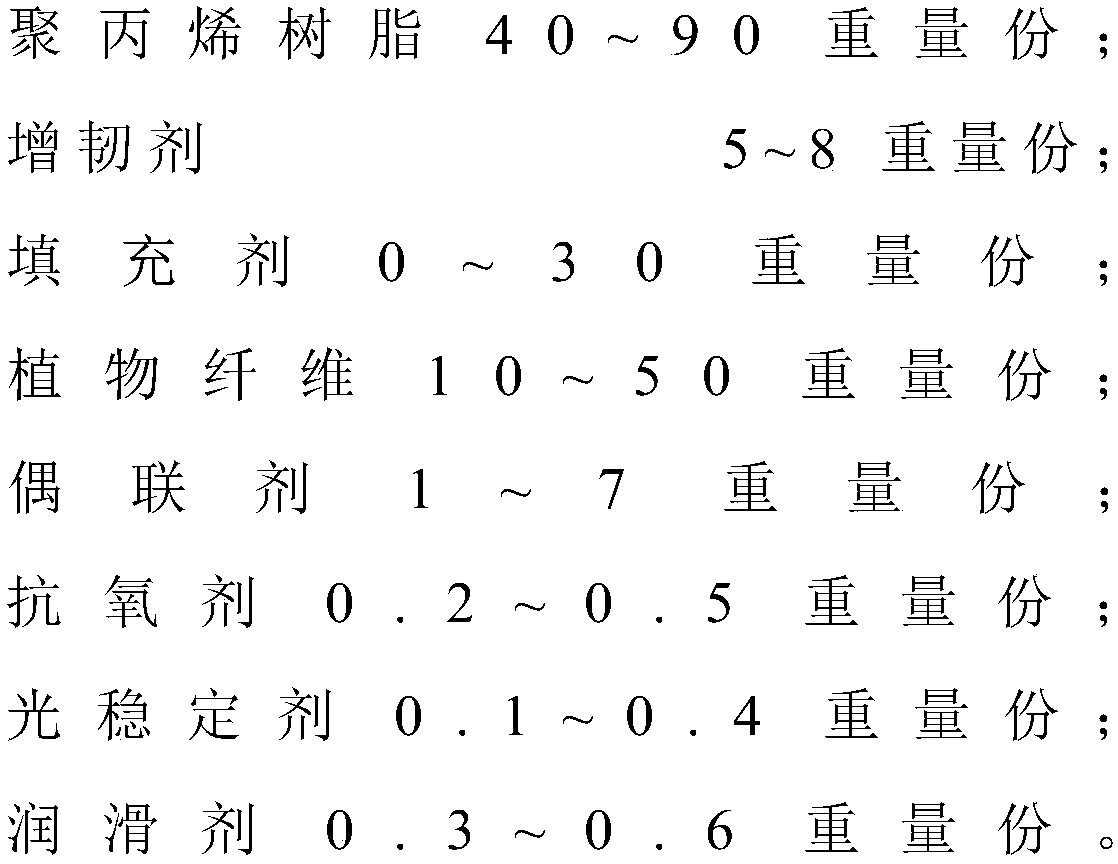

[0034] A segregation-resistant vegetable fiber modified polypropylene composite material made of:

[0035]

[0036] The preparation method of the anti-separation plant fiber modified polypropylene composite material, the steps are as follows:

[0037] (1) 37 parts by weight of wheat straw fiber, 5 parts by weight of talcum powder HTPultra5L, and 3 parts by weight of zirconium aluminate coupling agent were mixed in a high-speed mixer for 3 minutes to obtain a mixture A;

[0038] (2) 50 parts by weight of copolymerized polypropylene resin, 8 parts by weight of toughening agent POE8842, 0.3 parts by weight of antioxidant 1076, 0.2 parts by weight of antioxidant 168, 0.2 parts by weight of light stabilizer 3808PP5, and 0.5 parts by weight of lubricant TR451 Mix in a high-speed mixer for 5 minutes to obtain mixture B;

[0039] (3) Add compound A into the twin-screw extruder from the side feeding hopper, and add compound B into the twin-screw extruder from the main feeding hoppe...

Embodiment 2

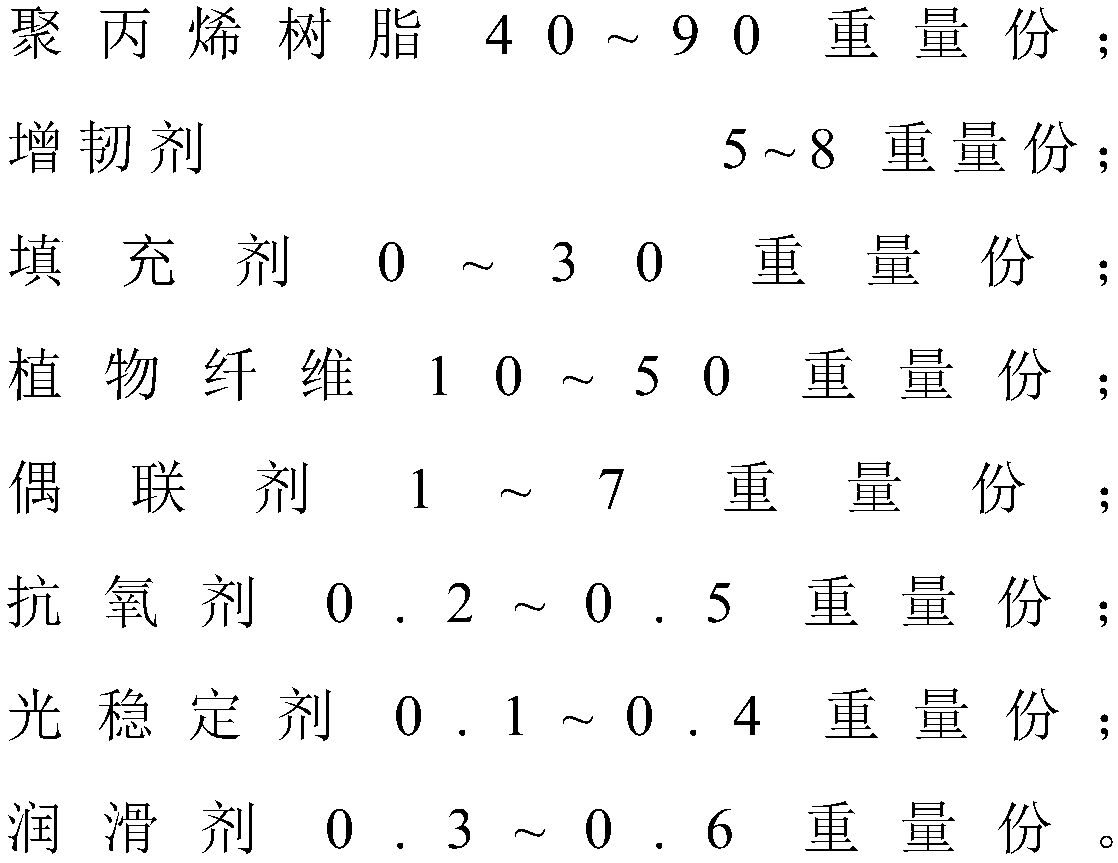

[0041] A segregation-resistant vegetable fiber modified polypropylene composite material made of:

[0042]

[0043] The preparation method of the anti-separation plant fiber modified polypropylene composite material, the steps are as follows:

[0044] (1) 25 parts by weight of hemp fiber, 20 parts by weight of talcum powder HTPultra5L, and 1 part by weight of zirconium aluminate coupling agent were mixed in a high-speed mixer for 3 minutes to obtain compound A;

[0045] (2) 70 parts by weight of homopolypropylene resin, 5 parts by weight of toughening agent POE875L, 0.3 parts by weight of antioxidant 1076, 0.2 parts by weight of antioxidant 168, 0.4 parts by weight of light stabilizer 5585, and 0.6 parts by weight of lubricant Mix TM-2153 in a high-speed mixer for 5 minutes to obtain mixture B;

[0046] (3) Add compound A into the twin-screw extruder from the side feeding hopper, and add compound B into the twin-screw extruder from the main feeding hopper, and then melt, e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com