Small-molecule hyaluronic acid stock solution

A technology of small molecule hyaluronic acid and stock solution, applied in the field of cosmetics, can solve the problems of no actual protection or repair effect of the dermis layer, and the duration is not long, and achieve the effects of high safety, improved skin repair, and improved compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] A method for preparing a small molecule hyaluronic acid stock solution, specifically comprising the following steps,

[0050] S1: Add the disodium EDTA and deionized water in the above parts by weight into the main pot and heat it at 90-95°C for 15-35 minutes, then lower the temperature to 70-75°C for the first time;

[0051] S2: Homogenize the sodium hyaluronate cross-linked polymer, sodium hyaluronate, acetylated sodium hyaluronate, and hydrolyzed sodium hyaluronate at 2300-2800 R / M for 2-5 minutes and then stir for 15-35 minutes. Minutes followed by the second cooling;

[0052] S3: When the temperature drops to 55-60°C for the second time in S2, add corresponding parts by weight of 1,2 pentanediol, butanediol, sodium polyglutamate, and acetyl glucosamine, and continue to cool down for the third time to After 40-45°C, add corresponding weight of purslane extract or / and gentian extract, 1,3 propylene glycol, glycerin, caprylyl hydroxamic acid, 1,2 hexanediol;

[0053...

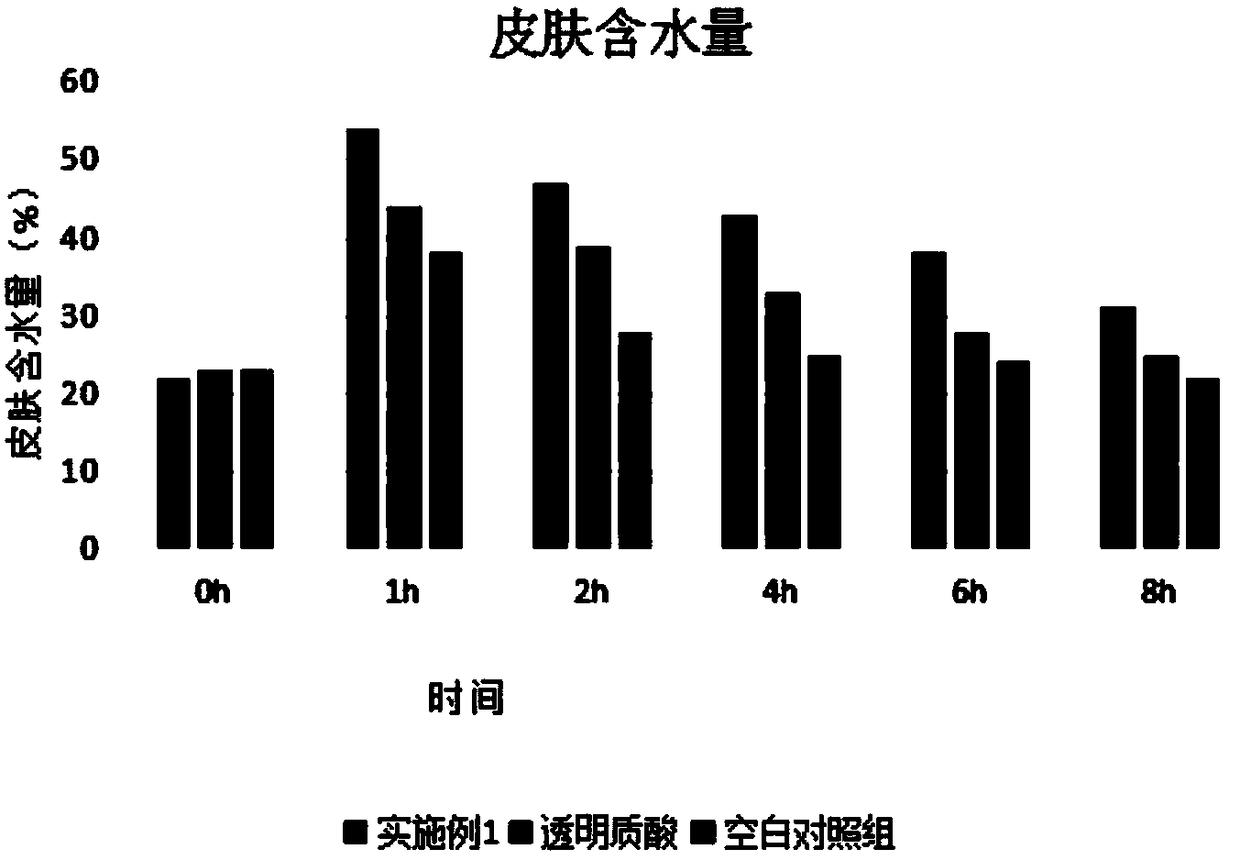

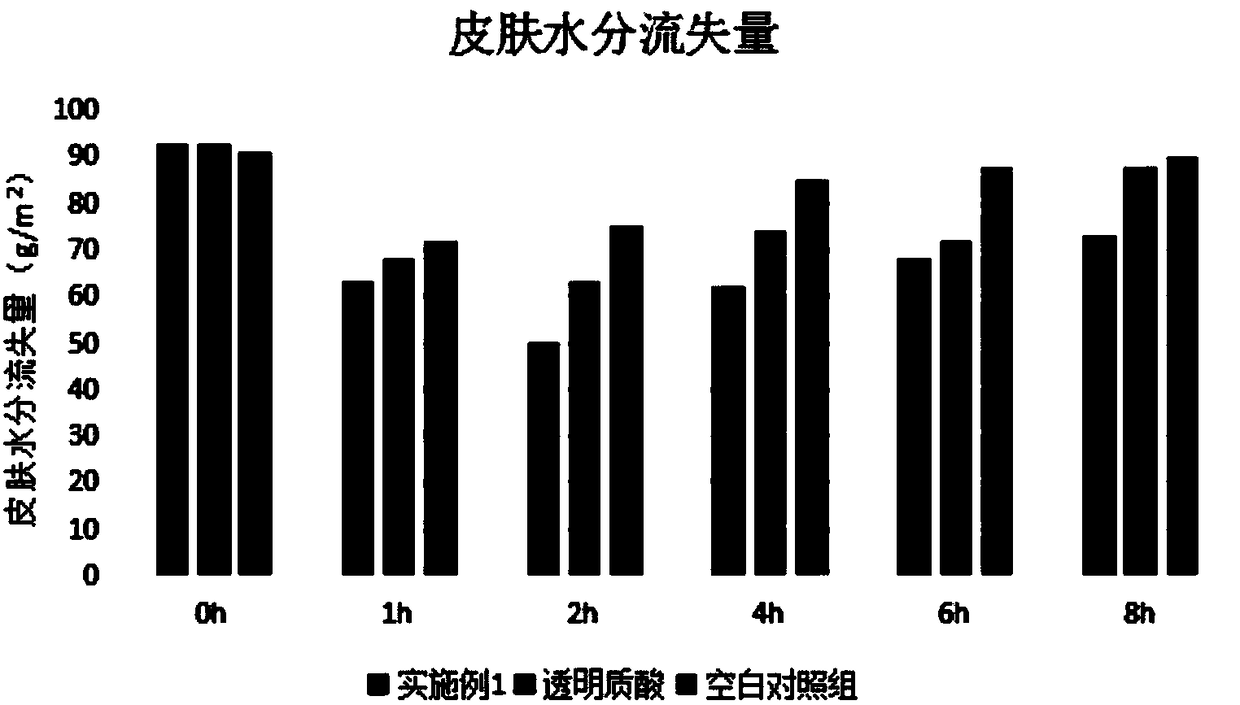

Embodiment 1

[0061] A small molecule hyaluronic acid stock solution, which comprises the following components in parts by weight: 0.05 parts of sodium hyaluronate cross-linked polymer, 10 parts of sodium hyaluronate, 1 part of acetylated sodium hyaluronate, and 3 parts of hydrolyzed sodium hyaluronate , 0.50 parts of 1,2 pentanediol, 5 parts of butanediol, 1 part of 1,3 propylene glycol and 0.5 parts of 1,2 hexanediol, 2 parts of purslane extract, 2 parts of sodium polyglutamate, acetyl shell 2 parts of sugar amine, 0.05 part of disodium EDTA, 1 part of glycerin, 0.05 part of caprylyl hydroxamic acid, 71.4 parts of deionized water.

[0062] The preparation method of the above-mentioned small molecule hyaluronic acid stock solution is:

[0063] S1: Add the disodium EDTA and deionized water in the above parts by weight into the main pot and heat it at 90-95°C for 30 minutes, then lower the temperature to 71°C for the first time;

[0064] S2: Homogenize the sodium hyaluronate cross-linked po...

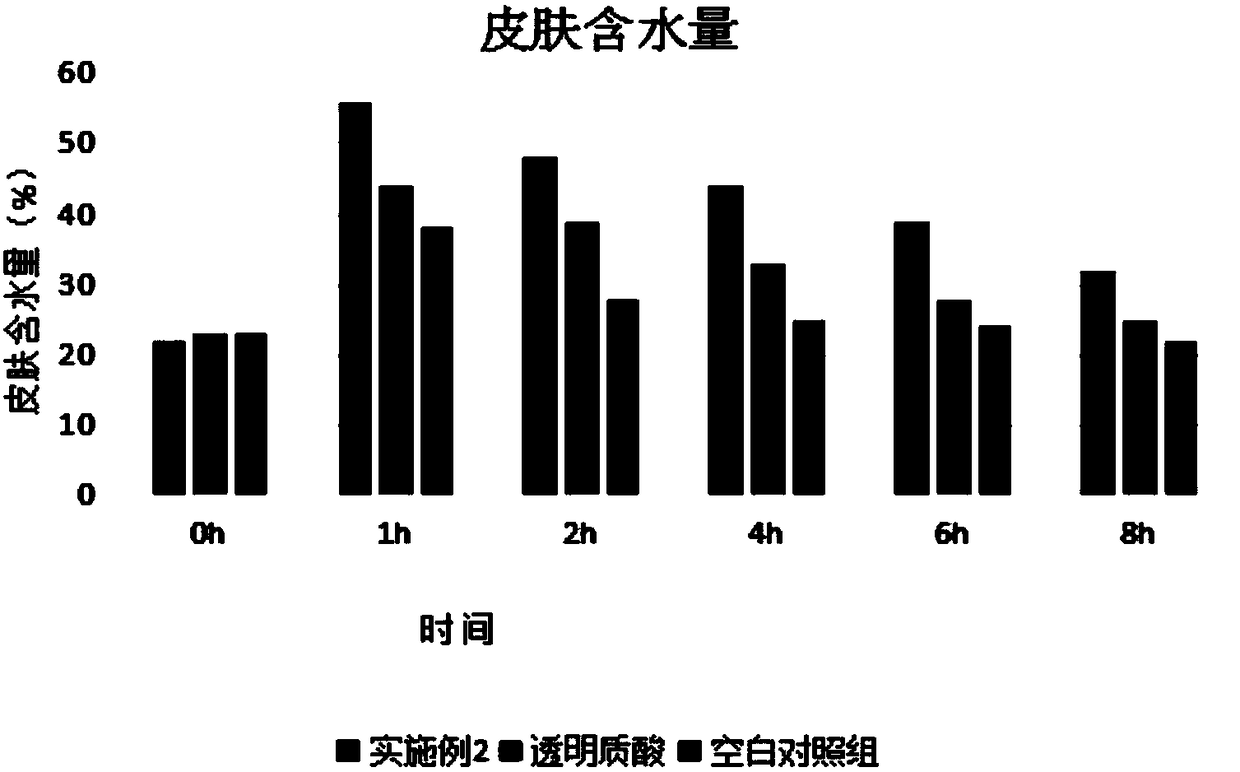

Embodiment 2

[0074] A small molecule hyaluronic acid stock solution, which includes the following components: 0.07 parts of sodium hyaluronate cross-linked polymer, 10 parts of sodium hyaluronate, 0.8 parts of acetylated sodium hyaluronate, 3.2 parts of hydrolyzed sodium hyaluronate, 0.5 parts of 1,2 pentanediol, 3 parts of butanediol, 1.2 parts of 1,3 propanediol and 0.5 parts of 1,2 hexanediol, 0.7 parts of purslane extract, 0.6 parts of gentian extract, polyglutamic acid 2.4 parts of sodium, 2 parts of acetylglucosamine, 0.04 parts of disodium EDTA, 1.2 parts of glycerin, 0.05 parts of caprylyl hydroxamic acid, and 65 parts of deionized water.

[0075] The preparation method of the above-mentioned small molecule hyaluronic acid stock solution is:

[0076] S1: Add the disodium EDTA and deionized water in the above parts by weight into the main pot and heat it at 95°C for 25 minutes, then lower the temperature to 70°C for the first time;

[0077] S2: Homogenize the sodium hyaluronate cro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mass volume concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com