Modified recycled coarse aggregate and method for preparing recycled concrete using modified recycled coarse aggregate

A technology of recycled coarse aggregate and recycled concrete, applied in the fields of recycled concrete and concrete, can solve the problems of low surface roughness of modified recycled coarse aggregate, low slump of recycled concrete, low dry shrinkage and creep, etc. , to achieve the effect of increasing strength, reducing water-binder ratio and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

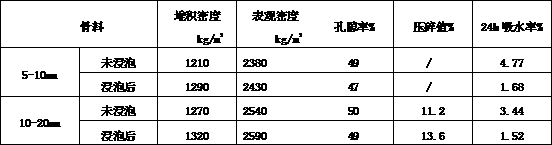

Embodiment 1

[0012] Embodiment 1, the modified recycled coarse aggregate of this embodiment is made by the following method: use a sand maker to crush the hardened waste concrete into recycled coarse aggregates of 5-10mm and 10-20mm . Soak the two kinds of regenerated coarse aggregate in the waste mud slurry with a solid content of 5% produced by the washing mixer truck and the mixing station, and circulate and soak for more than 24 hours according to the requirement of stirring for at least 5 minutes within 1 hour. Lay flat and sieve to prevent aggregates wrapped in waste mud liquid from sticking to each other to form large-volume cement blocks, and cool the under-sieve until the surface is dry. Mix the treated modified recycled coarse aggregate with a particle size of 5-10mm and the modified recycled coarse aggregate with a particle size of 10-20mm in a ratio of 40%:60%, and mix to form a particle size of 5-20mm Modified recycled coarse aggregate. The method for preparing recycled conc...

Embodiment 2

[0015] Embodiment 2, the other features of the modified regenerated coarse aggregate of this embodiment are the same as those of Embodiment 1, except that the solid content of the waste mud slurry is 9%, and the modified regenerated coarse aggregate with a particle size of 5-10mm after treatment The mixing ratio of raw material and modified recycled coarse aggregate with a particle size of 10-20mm is 45%: 55%. The other characteristics of the method for preparing recycled concrete in this embodiment are the same as those in Example 1, except that the volume ratio of the modified recycled coarse aggregate equal volume to replace the natural coarse aggregate is 25; the mixed coarse aggregate accounts for 45.79%, and the natural sand accounts for 32.45% , cement accounted for 10.00, fly ash accounted for 2.75, blast furnace slag powder accounted for 4.08, water reducing agent accounted for 0.31, and drinking water accounted for 7.96.

Embodiment 3

[0016] Embodiment 3, other features of the modified regenerated coarse aggregate of this embodiment are the same as those of Embodiment 1, except that the solid content of the waste mud slurry is 1%, and the modified regenerated coarse aggregate with a particle size of 5-10mm after treatment The mixing ratio of raw material and modified recycled coarse aggregate with a particle size of 10-20mm is 35%: 65%. Other characteristics of the method for preparing recycled concrete in this embodiment are the same as those in Example 1, except that the volume ratio of the modified recycled coarse aggregate equal volume to replace the natural coarse aggregate is 5; the mixed coarse aggregate accounts for 48.61, and the natural sand accounts for 30.56 , cement accounted for 9.8, fly ash accounted for 2.65, blast furnace slag powder accounted for 3.92, water reducing agent accounted for 0.29, and drinking water accounted for 7.64.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com