Preparation method of porous boron nitride foam material for water purification

A foam material and boron nitride technology, applied in chemical instruments and methods, applications, water pollutants, etc., can solve the problems of low stability of activated carbon, poor regeneration ability, etc., to overcome poor adsorption capacity, reduce consumption of raw materials, The effect of excellent regeneration and reuse ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Add 1 gram of boric acid into a container containing 1 liter of ethylamine, stir for 0.1 hour, then put the mixed solution into the container of the ultrasonic instrument, keep the water temperature in the container at 75°C, and the ultrasonic power at 5HKz , the ultrasonic time is 0.5 hours; (2) move the obtained product into a reactor with a reflux device, pass through an inert gas protection, and heat to 250 ° C, and keep it warm for 0.5 hours; (3) The obtained product in (2) The product of the product is placed in a reaction vessel, and the ammonia gas with a flow rate of 10 ml / min is fed into it, and the temperature rises to 900 °C at a heating rate of 2 °C / min, and is kept warm for 1 hour. When the temperature is lowered to room temperature, a porous boron nitride foam material for water purification is obtained.

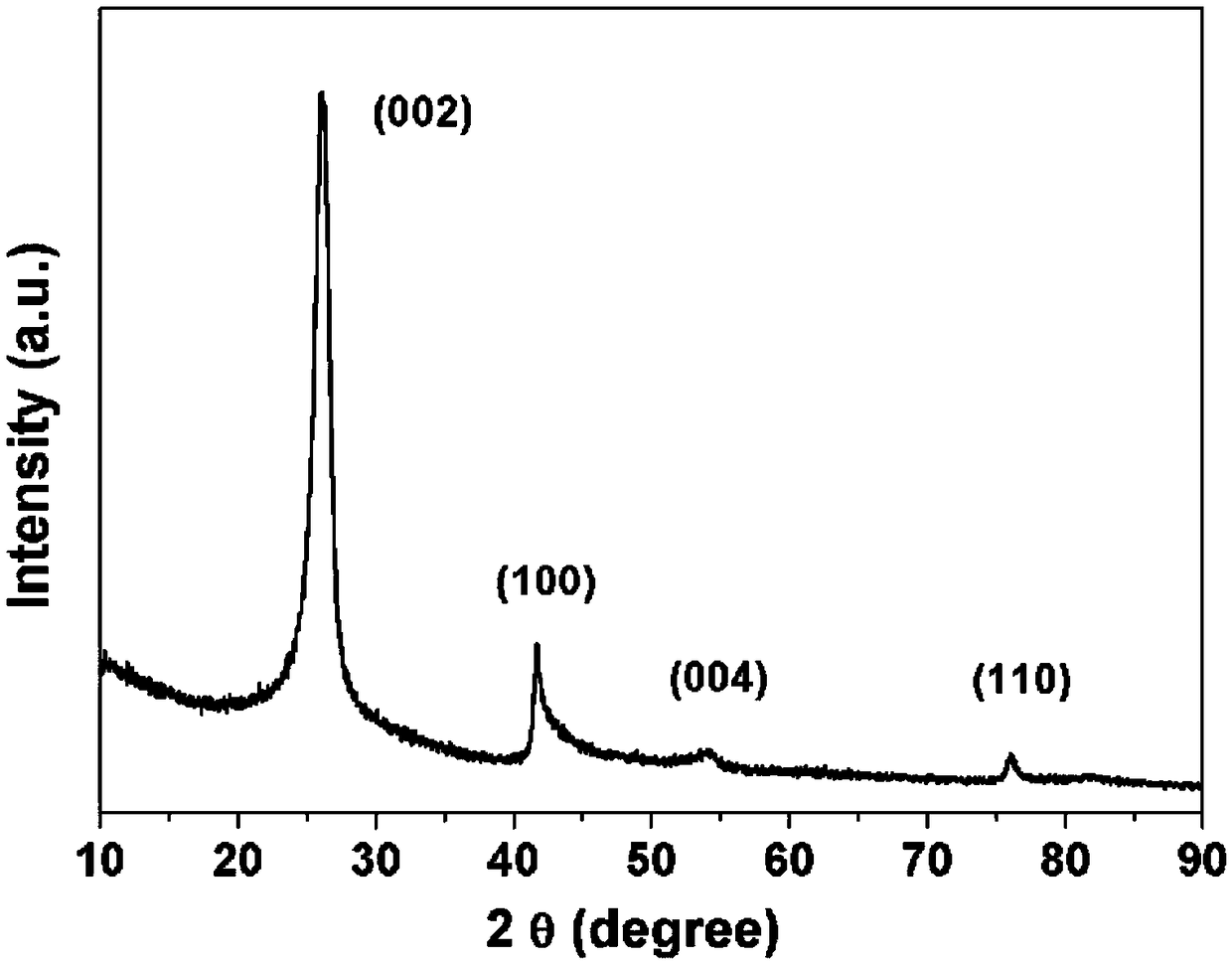

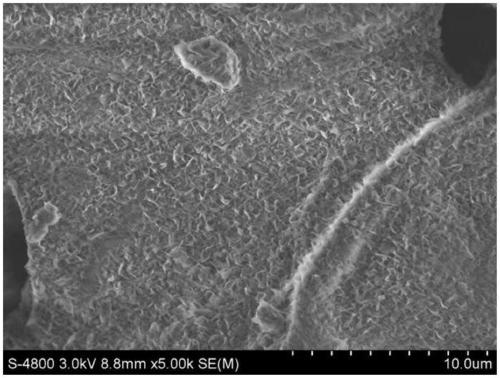

[0026] The porous boron nitride foam material obtained in the above-mentioned embodiment 1 is a foam block structure ( figure 1 ); powder X-ray di...

Embodiment 2、3

[0028] Change step (1) amine organic matter in embodiment 1 into diethylamine and ethylenediamine respectively, and other operations are all the same as in embodiment 1, and the product obtained is the same as in embodiment 1.

Embodiment 4、5

[0030] Change the consumption of step (1) amine organic matter into 20 grams, 50 grams respectively in the embodiment 1, other each operation is all the same with embodiment 1, obtains the product with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com