Functionalized polystyrene microspheres and preparation method and application thereof

A polystyrene microsphere, functionalized technology, applied in chemical instruments and methods, inorganic chemistry, alkali metal compounds, etc., can solve the problems of low metal ion removal efficiency and poor resin stability, and achieve improved stability. , to achieve the effect of recycling and reducing total nitrogen emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0021] According to a preferred embodiment of the present invention, the unsaturated acid is a mixture of unsaturated phosphoric acid and unsaturated sulfonic acid and / or unsaturated carboxylic acid, that is, the unsaturated acid is unsaturated phosphoric acid and unsaturated sulfonic acid or a mixture of unsaturated phosphoric acid and unsaturated carboxylic acid, or a mixture of unsaturated phosphoric acid, unsaturated sulfonic acid and unsaturated carboxylic acid, at this time, the corresponding functionalized polystyrene microspheres have a higher stability and removal efficiency of aluminum ions. Further, the weight ratio of the amount of unsaturated phosphoric acid to the total amount of unsaturated sulfonic acid and unsaturated carboxylic acid is preferably 1:(1-6), more preferably 1:(2-4). It should be noted that when the unsaturated acid contains only one of unsaturated sulfonic acid and unsaturated carboxylic acid, the total amount of unsaturated sulfonic acid and un...

Embodiment 1

[0032] (1) Preparation of functionalized polystyrene microspheres:

[0033] Add vinylphosphoric acid (30g), vinylsulfonic acid (30g), polystyrene microspheres (280g, particle size 0.5-3μm) and deionized water (500mL) into a 1L round bottom flask, magnetically stir, and nitrogen gas 20 minutes to remove oxygen from the solution, seal. The above-mentioned round bottom flask was then placed in 60 Irradiate 100kGy under the Co irradiation source. After the irradiation, the flask was opened, and the mixture in the bottle was packed into a column, washed with deionized water to remove unreacted monomers and homopolymers, and set aside. When packing the column, air bubbles should be prevented from remaining in the packing layer.

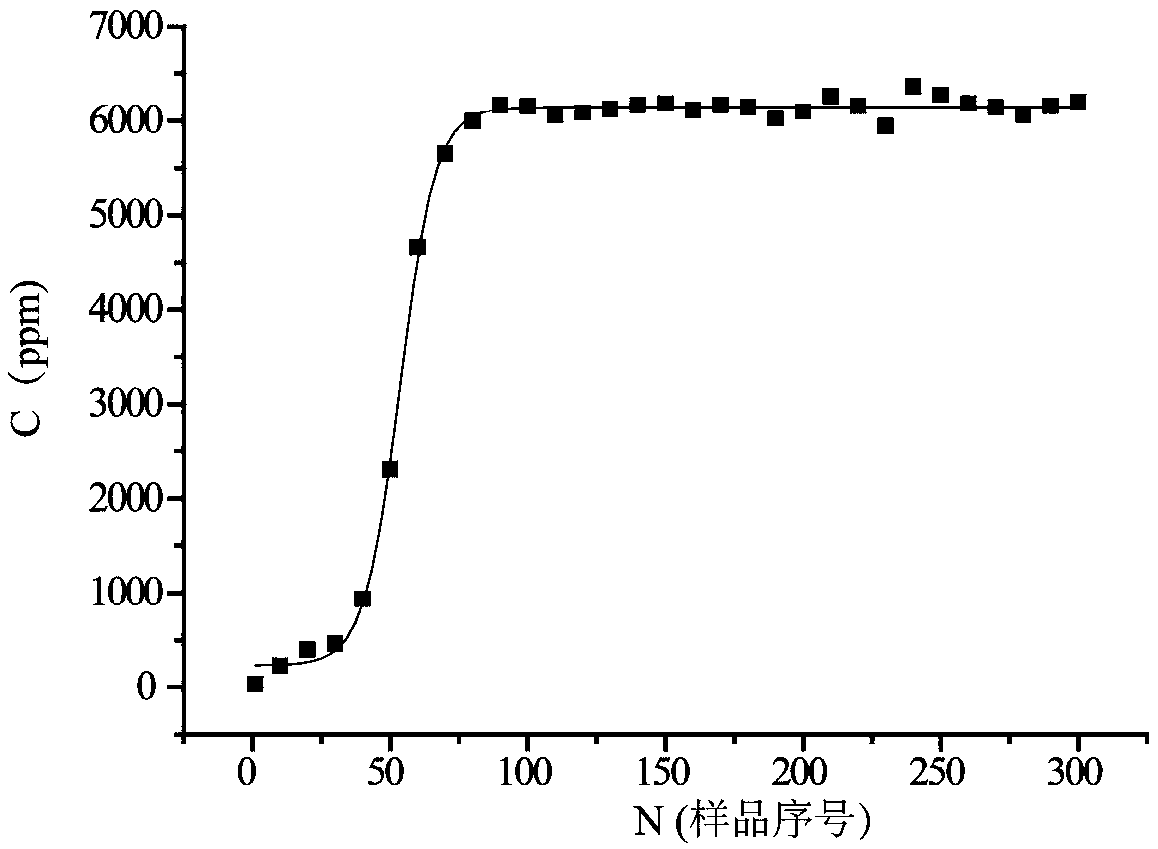

[0034] (2) Adsorption and removal of aluminum ions in aqueous nitric acid solution:

[0035] Nitric acid wastewater containing aluminum ions ([H + ]=0.1-2mol / L, [Al 3+]=0.2-1.0mol / L) from the top of the column to the packed column at a flow rate of 60...

Embodiment 2

[0042] (1) Preparation of functionalized polystyrene microspheres:

[0043] Into a 1 L round bottom flask were added vinyl phosphoric acid (10 g), vinyl sulfonic acid (30 g), acrylic acid (30 g), polystyrene microspheres (280 g, particle size 0.5–3 μm) and deionized water (500 mL), Stir magnetically, pass nitrogen gas for 20 minutes to remove oxygen in the solution, and seal. The above-mentioned round bottom flask was then placed in 60 Irradiate 100kGy under the Co irradiation source. After the irradiation, the flask was opened, and the mixture in the bottle was packed into a column, washed with deionized water to remove unreacted monomers and homopolymers, and set aside. When packing the column, air bubbles should be prevented from remaining in the packing layer.

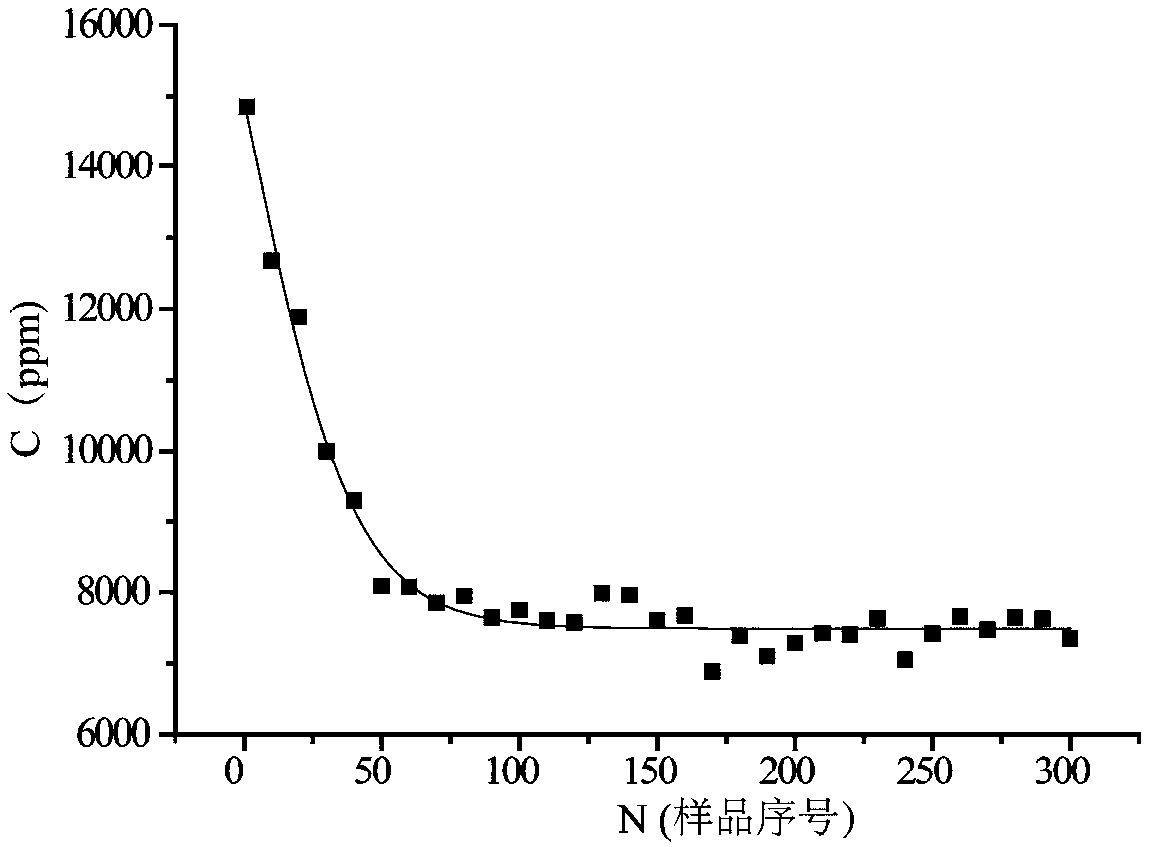

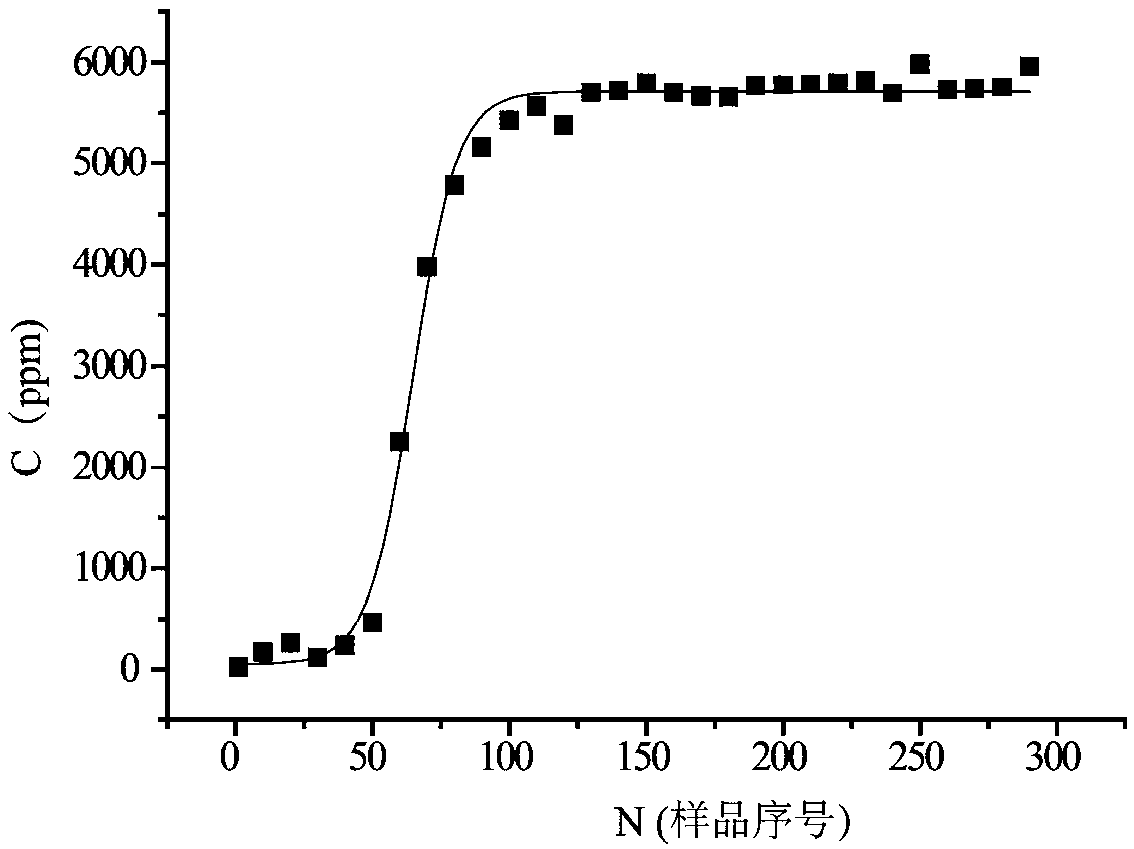

[0044] (2) Adsorption and removal of aluminum ions in aqueous nitric acid solution:

[0045] Nitric acid wastewater containing aluminum ions ([H + ]=0.1-2mol / L, [Al 3+ ]=0.2-1.0mol / L) from the top of the colu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com