Flame-retardant conductive nylon composite material and preparation method thereof

A nylon composite material and nylon technology, applied in the field of flame-retardant conductive nylon composite materials and their preparation, can solve the problems of composite material molding processing performance and mechanical performance degradation, and achieve improved electronic mobility, good conductivity, and excellent static elimination effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation method of modified conductive mica powder comprises the following steps:

[0025] 1) Calculated in parts by weight, weigh 40 parts of conductive mica powder, 10 parts of aluminum borate whiskers, 20 parts of conductive carbon black, 0.4 part of lubricating base oil and 0.6 part of aminopropyltrimethoxysilane for use;

[0026] 2) Mix conductive mica powder and aluminum borate whiskers evenly and roast in a vacuum furnace at 1100°C for 6 hours, cool the roasted product to room temperature, disperse the roasted product with chitosan aqueous solution, filter, and bake the filtered product Just dry;

[0027] 3) Stir and react the dried filtrate in step 2), conductive carbon black, aminopropyltrimethoxysilane and lubricating base oil at 75°C for 60 minutes.

Embodiment 2

[0029] The preparation method of modified conductive mica powder comprises the following steps:

[0030] 1) Calculated in parts by weight, weigh 50 parts of conductive mica powder, 5 parts of aluminum borate whiskers, 30 parts of conductive carbon black, 1.2 parts of lubricating oil base oil and 2.4 parts of isopropyltriethoxysilane for later use;

[0031] 2) Mix conductive mica powder and aluminum borate whiskers evenly and roast in a vacuum furnace at 1300°C for 3 hours, cool the roasted product to room temperature, disperse the roasted product with chitosan aqueous solution, filter, and bake the filtered product Just dry;

[0032] 3) Stir and react the dried filtrate in step 2), conductive carbon black, isopropyltriethoxysilane and lubricating base oil at 85°C for 30 minutes.

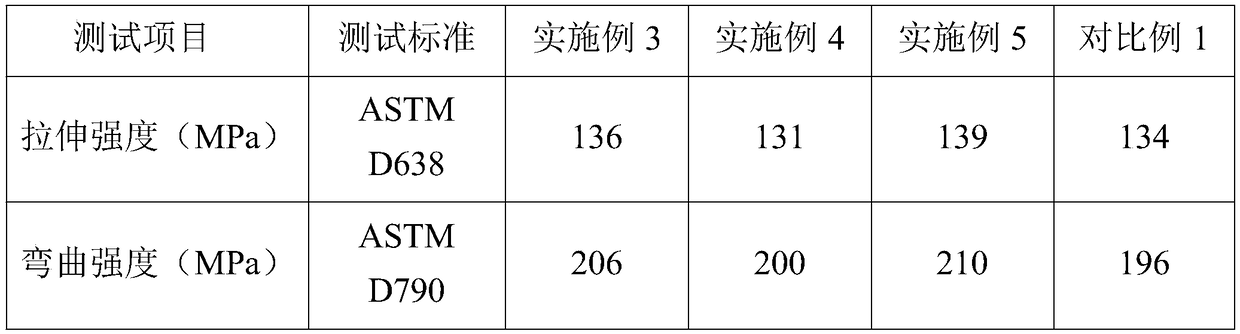

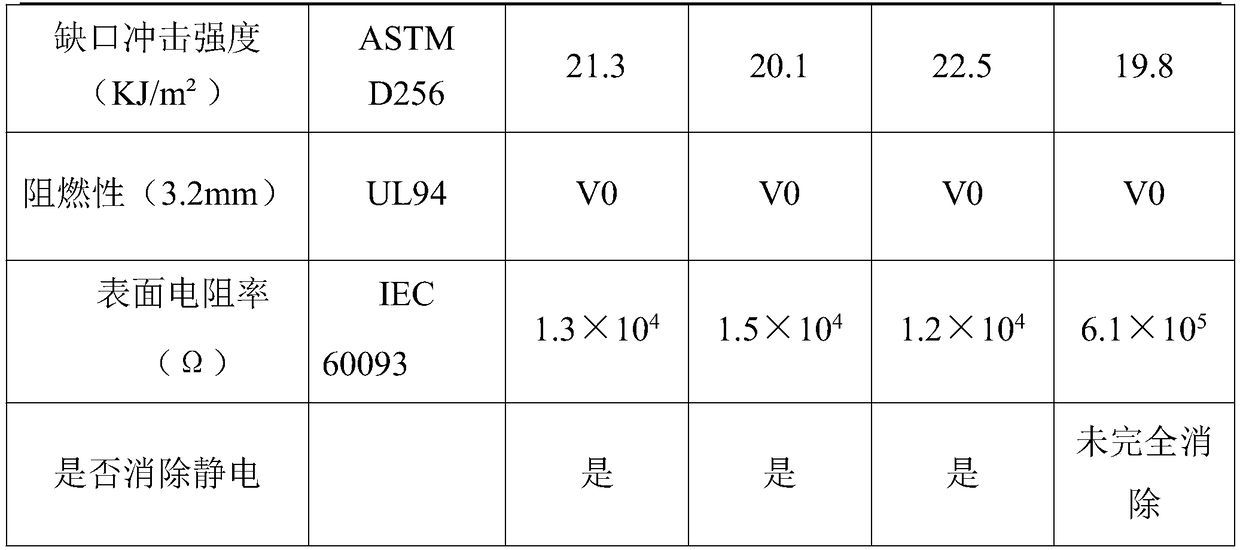

Embodiment 3

[0034] A flame-retardant conductive nylon composite material, calculated in parts by weight, includes the following raw materials:

[0035] 70 parts of nylon 610 resin, 118 parts of nylon, 15 parts of modified conductive mica powder of embodiment 1, 3 parts of aramid fiber, 2 parts of chromium oxide, 3 parts of zirconium oxide, 3 parts of decabromodiphenylethane, maleic anhydride 6 parts of grafted ethylene-octene copolymer, 0.8 part of styrene-maleic anhydride copolymer and tris[2,4-di-tert-butylphenyl]phosphite.

[0036] The preparation method of flame-retardant conductive nylon composite material comprises the following steps:

[0037] 1) First mix chromium oxide, zirconium oxide, the modified conductive mica powder of Example 1, nylon 610 resin, nylon 11 and maleic anhydride grafted ethylene-octene copolymer, and prepare master batches with a twin-screw extruder ;

[0038] 2) Mix the masterbatch obtained in step 1) with aramid fiber, antimony trioxide, tris[2,4-di-tert-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com