Method for preparing carotenoid degrading enzyme

A carotenoid and degrading enzyme technology is applied in the field of preparation of carotenoid degrading enzymes to achieve the effects of improving quality, improving quality and high promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

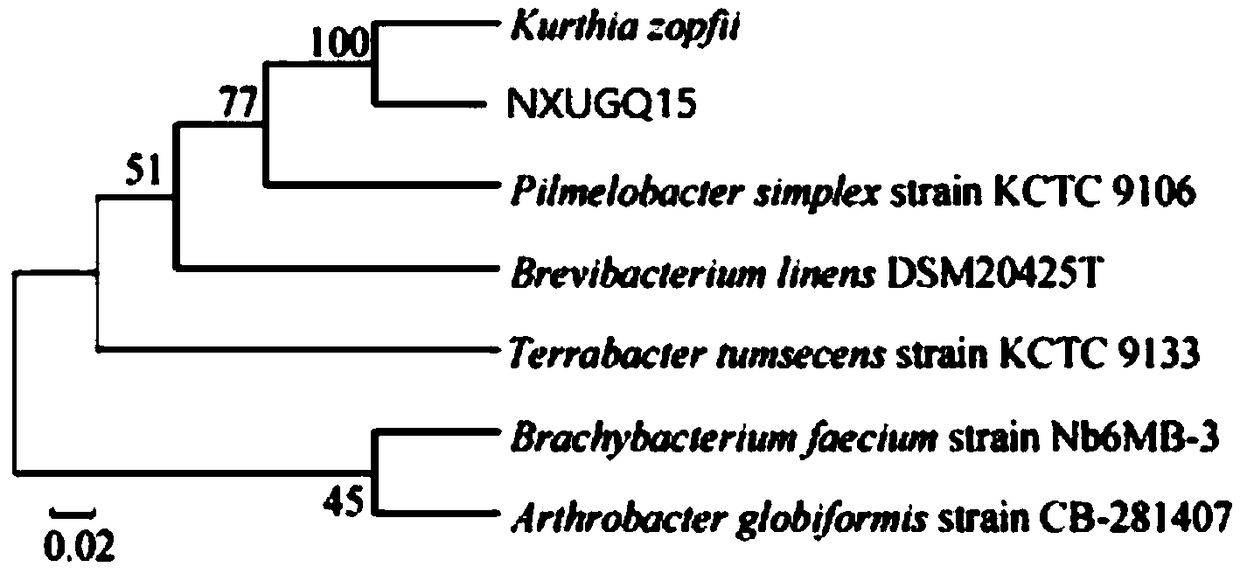

[0052] Isolation and Obtaining of Koutetella Strains

[0053] A carotenoid-degrading strain was isolated from wolfberry juice, and the Kurtella strain NXUGQ15 (Kurthia sp) was screened out by ultraviolet mutagenesis. The carotenoid-degrading enzyme produced by this strain was used to degrade carotenoids in wolfberry pulp Carotenoids can improve the brewing process of wolfberry wine and improve the quality of wolfberry wine. The starting strain of the bacterium was isolated by Zhang Huiling from the wolfberry juice in the planting base of Ningxia Bairuiyuan wolfberry Co., Ltd.

[0054] Kurthia sp. strain NXUGQ15 (Kurthia sp), preservation number CCTCC NO: M2017524, was deposited in China Center for Type Culture Collection (Wuhan) on September 21, 2017, address: China.Wuhan.Wuhan University. The bacteria can degrade β-carotene, the optimum growth temperature is 35-37℃, pH=2-3; the degrading enzyme produced by the bacteria can withstand the temperature of 70-90℃, and the optimal...

Embodiment 2

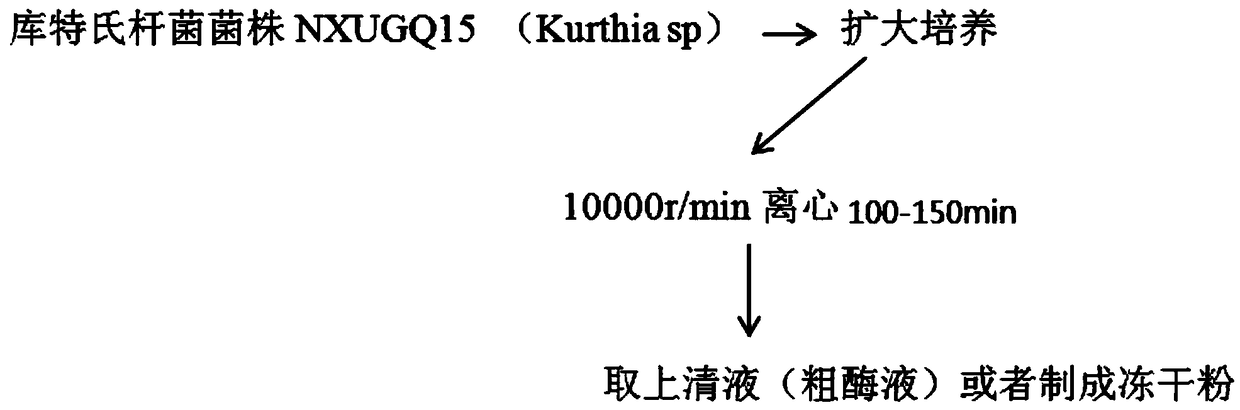

[0084] A preparation method of carotenoid degrading enzyme, comprising the steps of:

[0085] ①Preparation of Koutella liquid

[0086] Liquid medium (g / L): sodium nitrate 3, dipotassium hydrogen phosphate 1, magnesium sulfate 0.5, potassium chloride 0.5, iron sulfate 0.01, sucrose 30, YNB synthetic medium (amino-free yeast nitrogen source medium) 6.7, β-carotene 15; pH=3.2.

[0087] ② Expanded cultivation

[0088] Take a slant test tube of Kurthia sp NXUGQ15 1 ring → 10mL liquid culture medium at 35-37°C, 130r / min for 11h → 100mL liquid medium at 35-37°C, 130r / min for 11h → 3000mL liquid culture Cultivate at 35-37°C and 130r / min for 11h → the concentration of the bacterial solution reaches 10 6 cfu / ml → Kouteria seed solution;

[0089] ③ Fermentation

[0090] Liquid culture medium → inoculate 2% of Koutia seed solution → 33°C, pH=3.3, ferment at 140r / min for 9h → fermented liquid;

[0091] ④ Preparation of carotenoid degrading enzyme

[0092] Fermentation broth → 4°C, c...

Embodiment 3

[0099] A preparation method of carotenoid degrading enzyme, comprising the steps of:

[0100] ①Preparation of Koutella liquid

[0101] Liquid medium (g / L): sodium nitrate 3, dipotassium hydrogen phosphate 1, magnesium sulfate 0.5, potassium chloride 0.5, iron sulfate 0.01, sucrose 30, YNB synthetic medium (amino-free yeast nitrogen source medium) 6.7, β-carotene 15; pH=3.2.

[0102] ② Expanded cultivation

[0103] Take a slant test tube of Kurthia sp NXUGQ151 ring → 10mL liquid culture medium at 35-37°C, 130r / min for 10h → 100mL liquid medium at 35-37°C, 130r / min for 10h → 3000mL liquid medium Cultivate at 35-37°C and 130r / min for 10h → the concentration of the bacterial solution reaches 10 6 cfu / ml → Kouteria seed solution;

[0104] ③ Fermentation

[0105] Liquid culture medium → inoculate 2% of Kuetella seed solution → 30°C-32°C, pH=3.0-3.2, ferment at 140r / min for 10h → ferment liquid;

[0106] ④ Preparation of carotenoid degrading enzyme

[0107] Fermentation broth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com