Carbon tungsten cobalt composite material and preparation method and application thereof

A composite material, tungsten-cobalt technology, used in other manufacturing equipment/tools, turbines, engine components, etc., can solve the problems of undeveloped high-end tool materials and narrow application range, and achieve increased surface/interface energy, fine and uniform organization , the effect of excellent high temperature wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

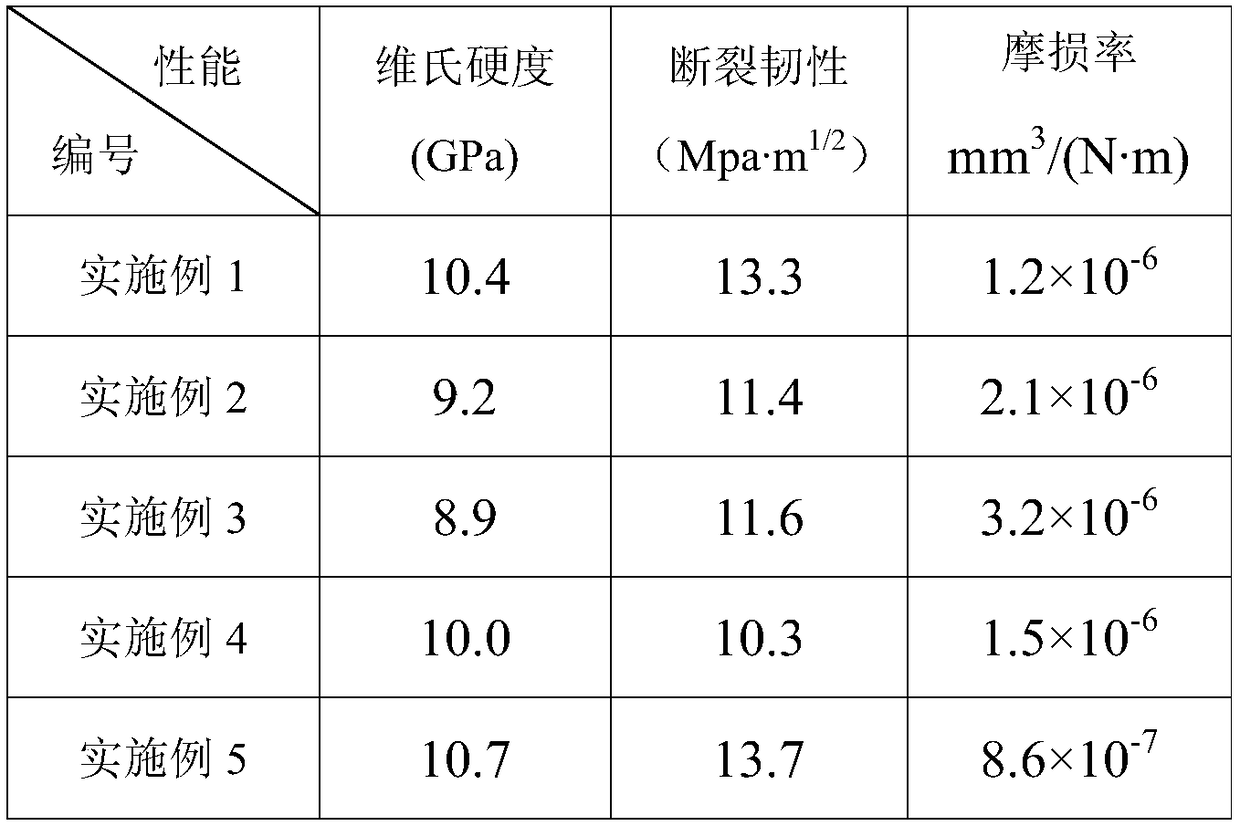

Embodiment 1

[0057] (1) In a glove box filled with argon protection, 30% tungsten powder, 55% cobalt powder and 15% graphite powder are mixed by mole percentage to obtain a mixed powder, tungsten powder, cobalt powder and graphite The purity of the powder was 99.9%, 99.8% and 99.5% respectively; the mixed powder was placed in a high-energy ball mill, the mass ratio of the ball and the mixed powder was controlled to be 5:1, the rotation frequency of the high-energy ball mill fixture was 17Hz, and the rotating speed was 1725r / min, high energy ball milling 15h;

[0058] (2) Put the powder obtained after high-energy ball milling in step (1) into a graphite grinding tool, put it into a discharge plasma sintering furnace, and heat it up to 900°C at a rate of 60°C / min for 5 minutes under 40MPa, and the sintering is completed After cooling with the furnace, a bulk carbon-tungsten-cobalt composite material is obtained.

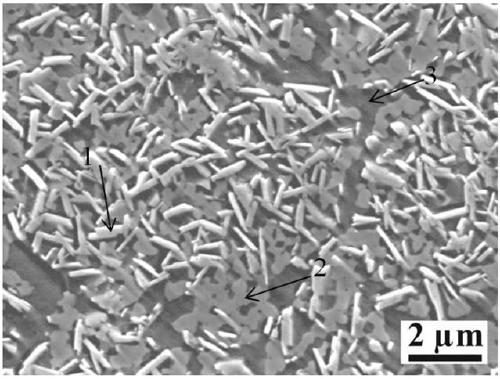

[0059] figure 1 This is the appearance diagram of the carbon-tungsten-cobal...

Embodiment 2

[0062] (1) In a glove box filled with argon protection, 35% tungsten powder, 50% cobalt powder and 15% graphite powder are mixed by mole percentage to obtain a mixed powder, tungsten powder, cobalt powder and graphite The purity of the powder was 99.9%, 99.8% and 99.5% respectively; the mixed powder was placed in a high-energy ball mill, the mass ratio of the ball and the mixed powder was controlled to be 4:1, the rotating frequency of the high-energy ball mill fixture was 18Hz, and the rotating speed was 1650r / min, high energy ball milling 9h;

[0063] (2) Put the powder obtained after high-energy ball milling in step (1) into a graphite grinding tool, put it into a discharge plasma sintering furnace, and heat it up to 800°C at a rate of 100°C / min for 30 minutes under 60MPa, and the sintering is completed After cooling in the furnace, a carbon-tungsten-cobalt composite material is obtained.

[0064] In the carbon-tungsten-cobalt composite material prepared in this example, ...

Embodiment 3

[0066] (1) In a glove box filled with argon protection, 25% tungsten powder, 65% cobalt powder and 10% graphite powder are mixed by mole percentage to obtain a mixed powder, tungsten powder, cobalt powder and graphite The purity of the powder was 99.9%, 99.8% and 99.5% respectively; the mixed powder was placed in a high-energy ball mill, the mass ratio of the ball and the mixed powder was controlled to be 10:1, the rotation frequency of the high-energy ball mill fixture was 15Hz, and the rotating speed was 1600r / min, high energy ball milling 20h;

[0067] (2) Put the powder obtained after high-energy ball milling in step (1) into a graphite grinding tool, put it into a discharge plasma sintering furnace, and heat it up to 1200°C at a rate of 50°C / min for 1min under 10MPa, and the sintering is completed After cooling with the furnace, a carbon-tungsten-cobalt composite material is obtained.

[0068] In the carbon-tungsten-cobalt composite material prepared in this example, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com