Chitosan/calcium alginate needleless electrospinning nanofiber membrane for medical dressings and preparation method thereof

A nanofiber, chitosan technology, applied in the chemical characteristics of fibers, textiles and papermaking, conjugated rayon, etc., can solve the problem of low use efficiency, achieve high processing efficiency, improve performance, and good hemostatic effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

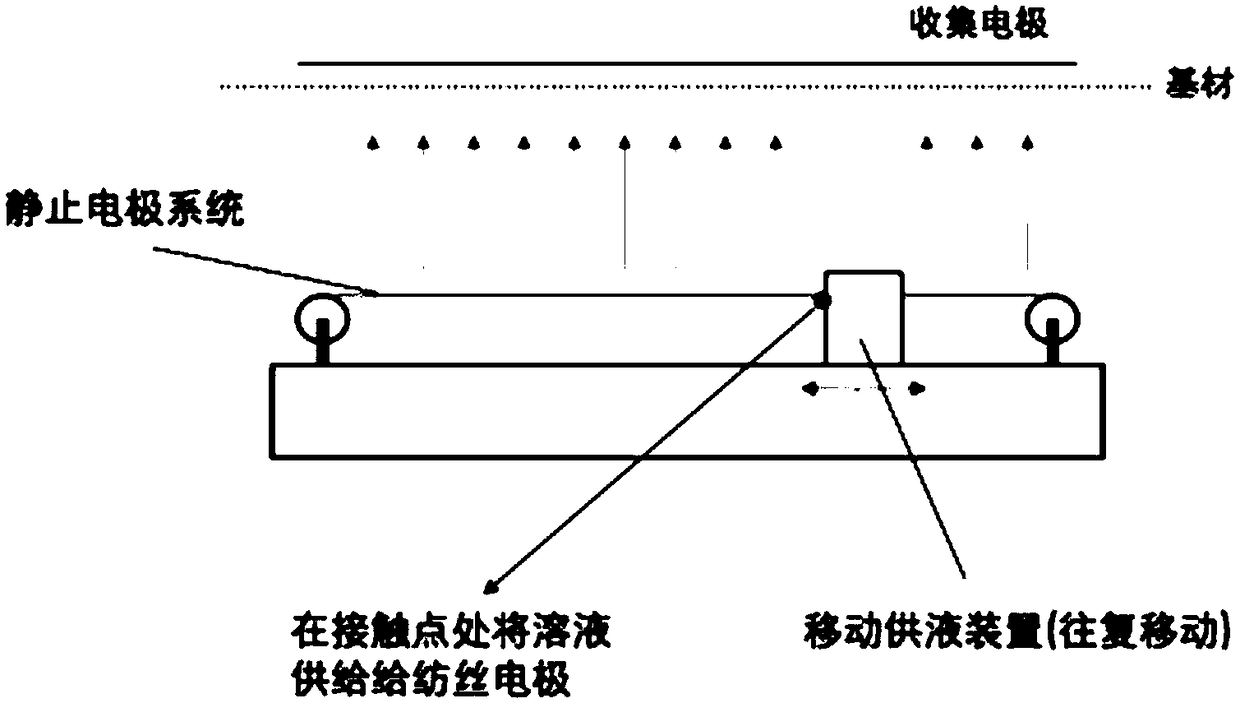

Embodiment 1

[0037]Sodium alginate was directly dissolved in deionized water to make a 1wt% solution, and stirred at 80°C until the solution was transparent; chitosan was directly dissolved in 50wt% acetic acid solution in water, and made into a 1.5wt% solution at room temperature Stir at low temperature until the solution is transparent; dissolve PEO in deionized water to prepare an 8wt% solution, and stir at room temperature until the solution is transparent; mix the aqueous solution of sodium alginate and the aqueous solution of PEO at a volume ratio of 2:8, and stir for 10 hours to obtain Uniform sodium alginate / PEO solution; mix chitosan acid solution and PEO aqueous solution at a volume ratio of 5:5, and stir for 10 hours to obtain a uniform chitosan / PEO solution; mix chitosan / PEO solution with alginic acid Sodium / PEO solution was placed in needle-free electrospinning ( figure 1 As shown) the left and right sides of the solution box (at this time, the volume ratio of the three soluti...

Embodiment 2

[0040] Sodium alginate is directly dissolved in deionized water, prepared into a 1.5wt% solution, stirred at 80°C until the solution is transparent; chitosan is directly dissolved in 50wt% acetic acid solution, prepared into a 2wt% solution, in Stir at room temperature until the solution is transparent; dissolve PVP in deionized water to prepare a 10wt% solution, and stir at room temperature until the solution is transparent; mix sodium alginate aqueous solution and PVP aqueous solution at a volume ratio of 5:5, and stir for 10 hours. Obtain a uniform sodium alginate / PVP solution; mix chitosan acid solution and PVP aqueous solution at a volume ratio of 3:7, and stir for 10 hours to obtain a uniform chitosan / PVP solution; mix chitosan / PVP solution with seaweed NaCl / PVP solutions were placed in needle-free electrospinning ( figure 1 As shown) the left and right sides of the solution box (at this time, the volume ratio of the three solutions of sodium alginate aqueous solution, c...

Embodiment 3

[0042] Sodium alginate was directly dissolved in deionized water to make a 2wt% solution, and stirred at 80°C until the solution was transparent; chitosan was directly dissolved in 50wt% acetic acid solution to make a 1.5wt% solution at room temperature Stir under low pressure until the solution is transparent; dissolve PEO in deionized water to prepare an 8wt% solution, stir at room temperature until the solution is transparent; mix the aqueous solution of sodium alginate and the aqueous solution of PEO at a volume ratio of 1:9, and stir for 10 hours to obtain Uniform sodium alginate / PEO solution; mix chitosan acid solution and PEO aqueous solution at a volume ratio of 1:9, and stir for 10 hours to obtain a uniform chitosan / PEO solution; mix chitosan / PEO solution with alginic acid The sodium / PEO solution was placed on the left and right sides of the needle-free electrospinning solution box (at this time, the volume ratio of the three solutions of sodium alginate aqueous soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com