A method for preparing conductive polystyrene particles with core-shell structure by using waste polystyrene

A technology of polystyrene particles and waste polystyrene, which is applied in the field of environmental protection, can solve the problems of high percolation threshold value of conductive polystyrene materials, decreased mechanical properties and processing performance, large filling amount of conductive fillers, etc., and can prevent electromagnetic waves. and radio frequency interference, low preparation cost and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

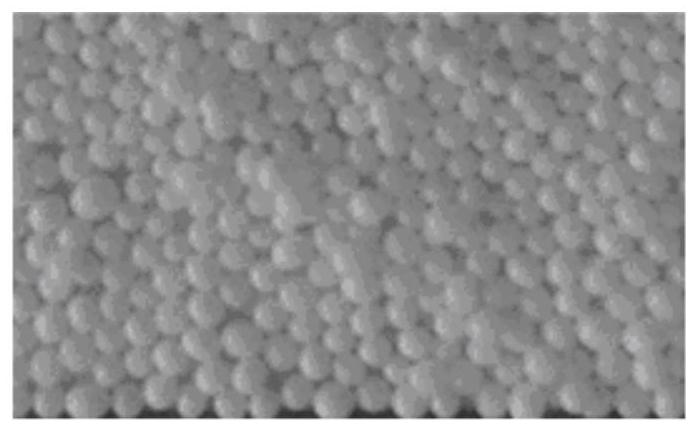

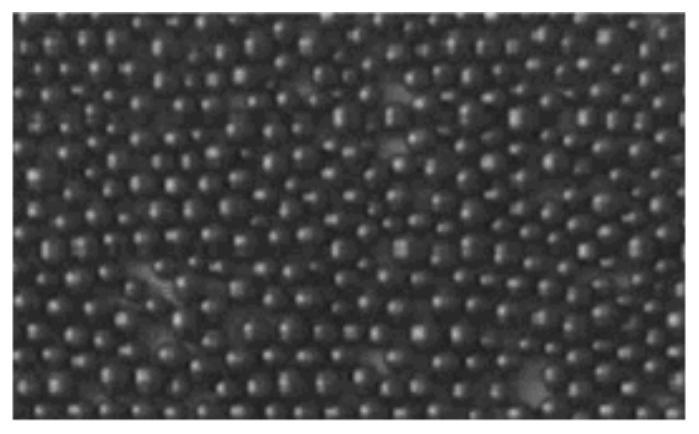

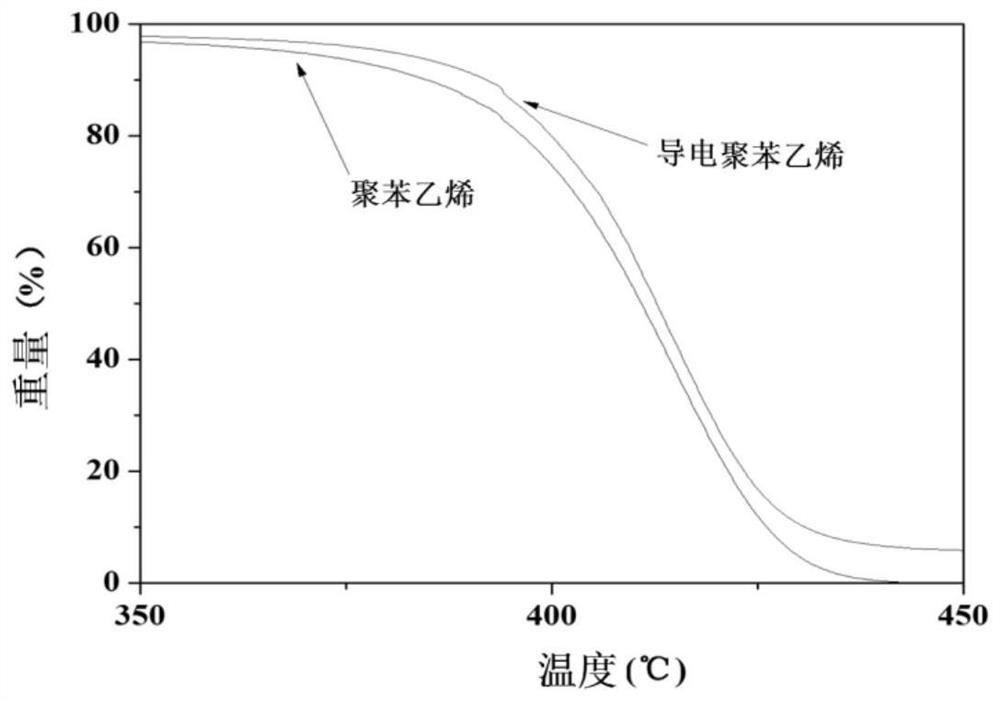

[0045]In a three-neck flask with a capacity of 1 liter, a stirring paddle is installed in the middle port, a condenser is installed in one side port, and condensed water is introduced. Add 300ml of absolute ethanol and 160ml of dichloromethane from the other side port, and add 40g of graphene under stirring to obtain a mixed system of dichloromethane and ethanol of graphene, and stir evenly. Add 200 g of polystyrene particles with a diameter of 1 mm, prepared by functionalized remodeling of waste polystyrene, stir for 2 hours, add 200 ml of absolute ethanol, filter and dry to obtain black conductive polystyrene particles.

Embodiment 2

[0047] In a 100-liter reactor, open the cold water inlet valve and outlet valve of the reflux condenser, add 33L methanol and 20L benzene from the feed pipeline, turn on the stirrer switch, adjust the stirring speed to 90rpm, and add 5kg 1000 mesh graphite powder from the feed inlet , continue to stir until uniform, add 40kg 1.0-1.2mm expandable polystyrene particles from the feed port, prepared by the method of functional remodeling of waste polystyrene, add 15L methanol after stirring for 2 hours, filter out and dry to obtain Black graphite expandable polystyrene conductive particles.

Embodiment 3

[0049] In a 1-liter three-necked flask, a stirring paddle is installed in the middle port, a condenser is installed in the side port, and condensed water is introduced. Add 200ml of chloroform and 240ml of methanol from the other side port, stir evenly, add 30g of 1500 mesh conductive carbon black and continue stirring to obtain a mixed solution of chloroform and methanol of conductive carbon black. Add 100g of polystyrene particles with a diameter of 1 mm from the other side port, prepared by the method of functionalized remodeling of waste polystyrene, stir for 2 hours, add 200ml of methanol, and filter out black polystyrene particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com