Polyurethane foam for preventing electromagnetic radiation

A polyurethane foam, anti-electromagnetic radiation technology, applied in the field of special foam materials, can solve the problems of high cost, poor anti-electromagnetic radiation capability, low electromagnetic shielding efficiency, etc., and achieve the effects of low cost, reduced mixing performance and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

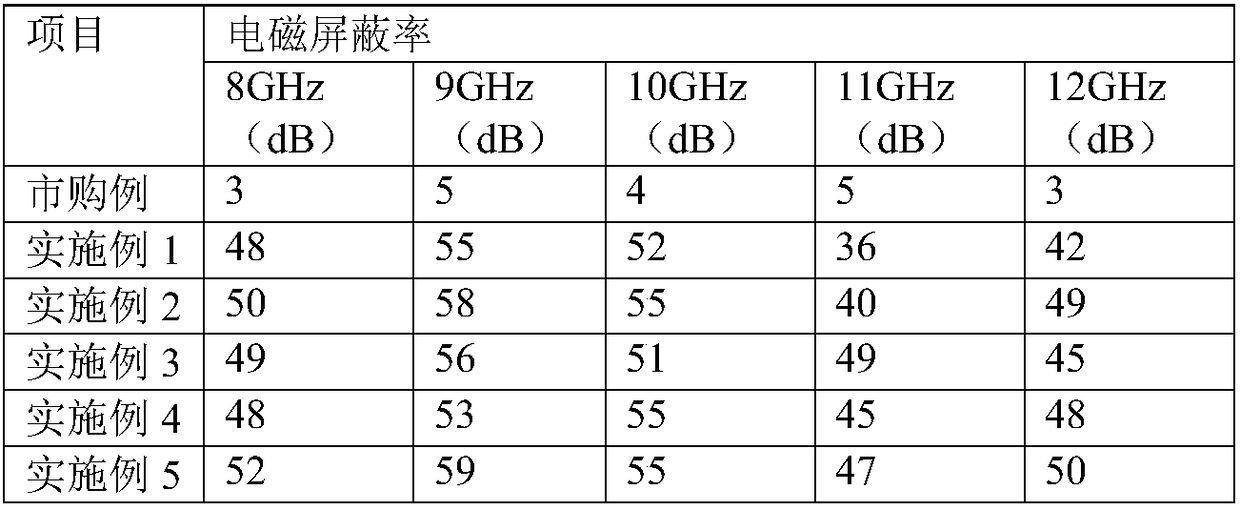

Examples

Embodiment 1

[0029] An anti-electromagnetic radiation polyurethane foam, said foam includes the following components in parts by weight: 100 parts of siloxane-modified phthalic anhydride polyester polyol, 80 parts of dimethylene benzene diisocyanate, nano-lead silicon tungstate 10 parts of gel, 25 parts of powdered graphene microflakes with a thickness of 40-80 nanometers and a width of 5-20 microns, 5 parts of carboxymethyl starch, 3 parts of melamine, 5 parts of ammonium polyphosphate, and 1 part of triethylenediamine , 0.5 parts of water, and 0.05 parts of dibutyltin dilaurate.

[0030] The preparation method of described siloxane modified phthalic anhydride polyester polyol is as follows:

[0031] (1) Preparation of silicone-modified polyol: take 100 parts of propylene glycol according to parts by weight, then add 5 parts of tetraethyl orthosilicate to it and stir evenly, then continue to add 0.5 part of glacial acetic acid and water 10 parts, and then stirred and reacted at 40°C for ...

Embodiment 2

[0036]An anti-electromagnetic radiation polyurethane foam, said foam comprises the following components in parts by weight: 100 parts of siloxane-modified phthalic anhydride polyester polyol, 100 parts of 1,4-cyclohexane diisocyanate, nano-tungstic acid 25 parts of lead-silica gel, 35 parts of powdered graphene microflakes with a thickness of 40-80 nanometers and a width of 5-20 microns, 15 parts of carboxymethyl starch, 8 parts of melamine, 10 parts of ammonium polyphosphate, triethylenediamine 3 parts, 3 parts of water, 0.25 parts of dibutyltin dilaurate.

[0037] The preparation method of described siloxane modified phthalic anhydride polyester polyol is as follows:

[0038] (1) Preparation of silicone-modified polyols: take 100 parts of propylene glycol in parts by weight, then add 10 parts of tetraethyl orthosilicate to it and stir evenly, then continue to add 2 parts of glacial acetic acid and water 15 parts, then stirred and reacted at 60°C for 5 hours, and evaporated ...

Embodiment 3

[0043] An anti-electromagnetic radiation polyurethane foam, said foam comprises the following components in parts by weight: 100 parts of siloxane-modified phthalic anhydride polyester polyol, 85 parts of isocyanate, 15 parts of nano-lead tungstate silica gel, thickness 25 parts of powdered graphene microflakes of 40 to 80 nanometers and a width of 5 to 20 microns, 10 parts of carboxymethyl starch, 5 parts of melamine, 8 parts of calcium polyphosphate, 1 part of triethylenediamine, 0.5 parts of water parts, 0.05 parts of dibutyltin dilaurate.

[0044] The preparation method of described siloxane modified phthalic anhydride polyester polyol is as follows:

[0045] (1) Preparation of silicone-modified polyols: take 100 parts of propylene glycol in parts by weight, then add 8 parts of tetraethyl orthosilicate to it and stir evenly, then continue to add 1 part of glacial acetic acid and water 12 parts, and then stirred and reacted at 50°C for 3 hours, and evaporated under reduced...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com