Surface-modified magnetic halloysite nanotube inner and outer walls simultaneously immobilized chloroperoxidase reactor and its application

A halloysite nanotube, chloroperoxidase technology, applied in the directions of oxidoreductase, immobilized on or in an inorganic carrier, enzyme, etc., can solve the problem of changing the surface electrical properties of halloysite nanotubes, enzyme immobilization The problem of low load is achieved, and the stability and operation stability are improved, objective economic benefits, and the effect of increasing the fixed load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Preparation of magnetic halloysite nanotubes

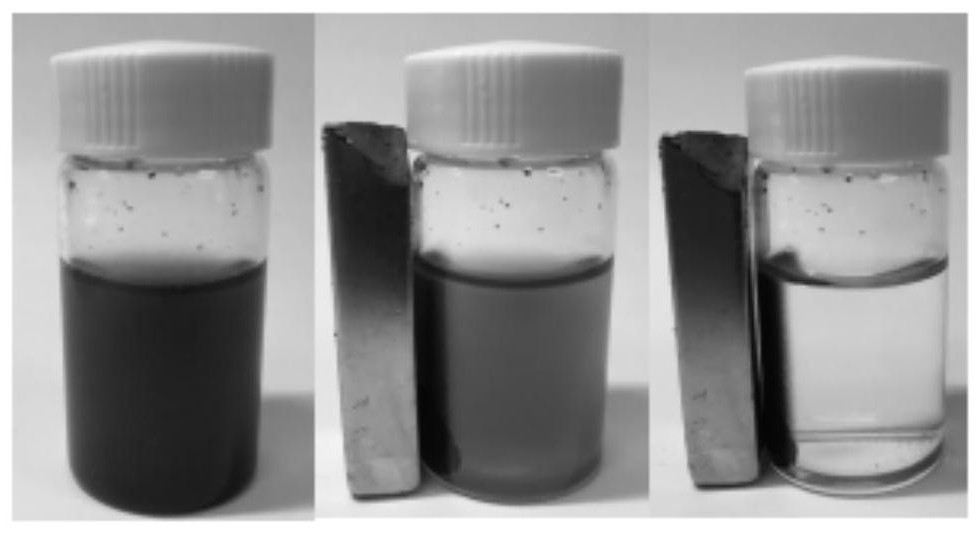

[0023] Weigh 5g of halloysite nanotubes into a 600mL beaker, add 400mL of deionized water, sonicate for 15min, continue to add 3.8g of FeCl 3 ·6H 2 O and 3g FeSO 4 ·7H 2 O, after completely dissolving, transfer to a three-neck flask, add 3 to 5 drops of concentrated hydrochloric acid, and pass through N 2 , After 3 hours in an oil bath at 120°C, stop heating and cool to 50°C. Then add 4moL·L dropwise -1 NaOH aqueous solution, adjust the pH value to 9-10, continue to stir at 50°C for 2.5h, obtain a black solid and collect it with a strong magnet, alternately centrifuge and wash with deionized water and absolute ethanol until the supernatant is colorless, and vacuum dry at 50°C for 6h , to obtain magnetic halloysite nanotubes.

[0024] 2. Preparation of surface-modified magnetic halloysite nanotubes

[0025] Weigh 2g of magnetic halloysite nanotubes into a 250mL beaker, add 100mL of absolute ethanol, and stir at a s...

Embodiment 2

[0055] Adopt the CPO@HNTs-Fe that embodiment 1 prepares 3 o 4 -APTES-PEI degradation of rifaximin

[0056] 1. Preparation of mobile phase

[0057] Weigh KH 2 PO 4 3.4g, dissolve and make up to volume in a 250mL volumetric flask, weigh 2.05g of NaAc, dissolve and make up to volume in a 250mL volumetric flask, then mix the two in equal volumes. Use 0.1mol·L -1 Aqueous citric acid solution is used to adjust the pH of the solution to 2.6, and this solution is a buffer solution. Acetonitrile, methanol, buffer volume ratio = 44:16:40 as the mobile phase.

[0058] 2. Degradation of rifaximin

[0059] Using distilled water as solvent, prepare samples of rifaximin standard solution (10 μg / mL, 20 μg / mL, 30 μg / mL, 30 μg / mL, 40 μg / mL, 50 μg / mL) with different concentrations; take five 10 mL centrifuge tubes respectively Add 500 μL rifaximin standard solution, 2400 μL PBS buffer solution (pH=2.75), 10 mg CPO@HNTs-Fe 3 o 4 -APTES-PEI, 100 μL of 30% H 2 o 2 Solution, react at room...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Loading capacity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com